Subaqueous explosion pressure measurement device based on improved Hopkinson bar

A Hopkinson rod and measuring device technology, applied in the direction of measuring device, measuring blasting force, measuring rapid change, etc., can solve the problems of easy failure, sensor damage, short recording time, etc., and achieves low cost, large measuring range, and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

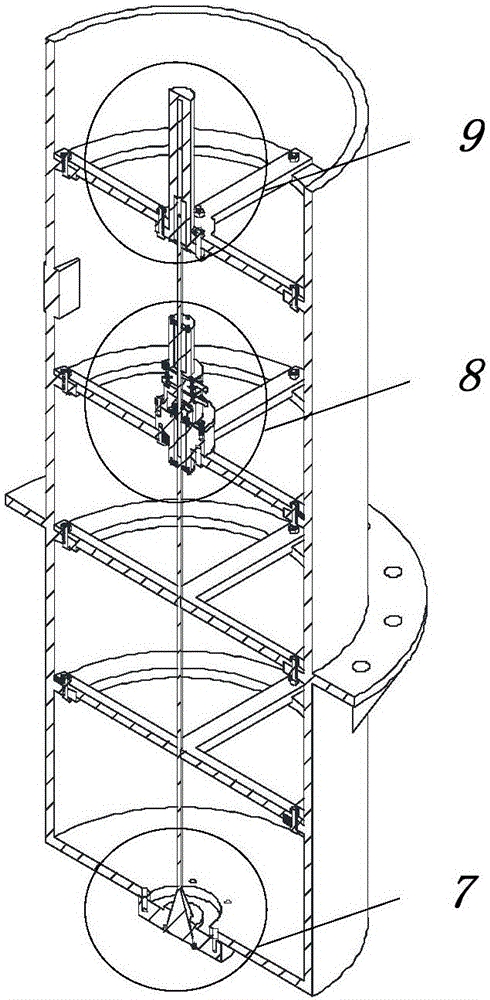

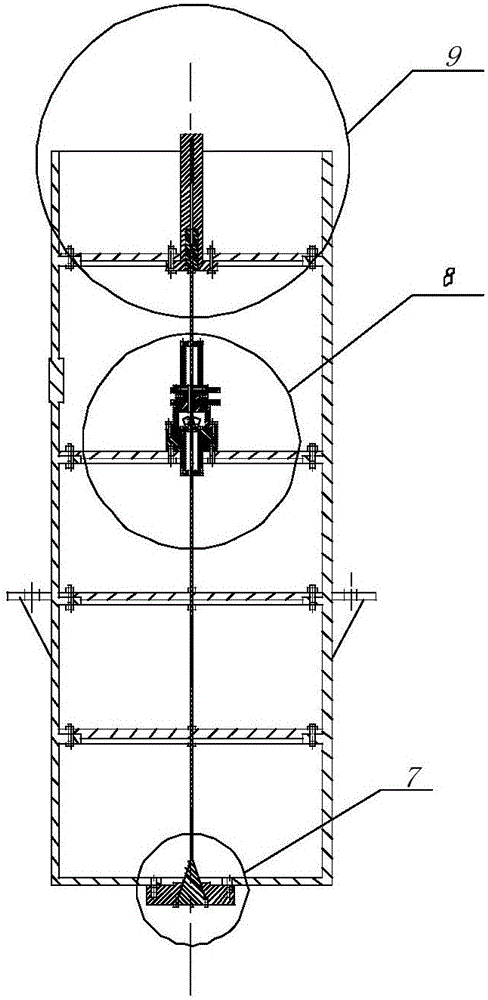

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

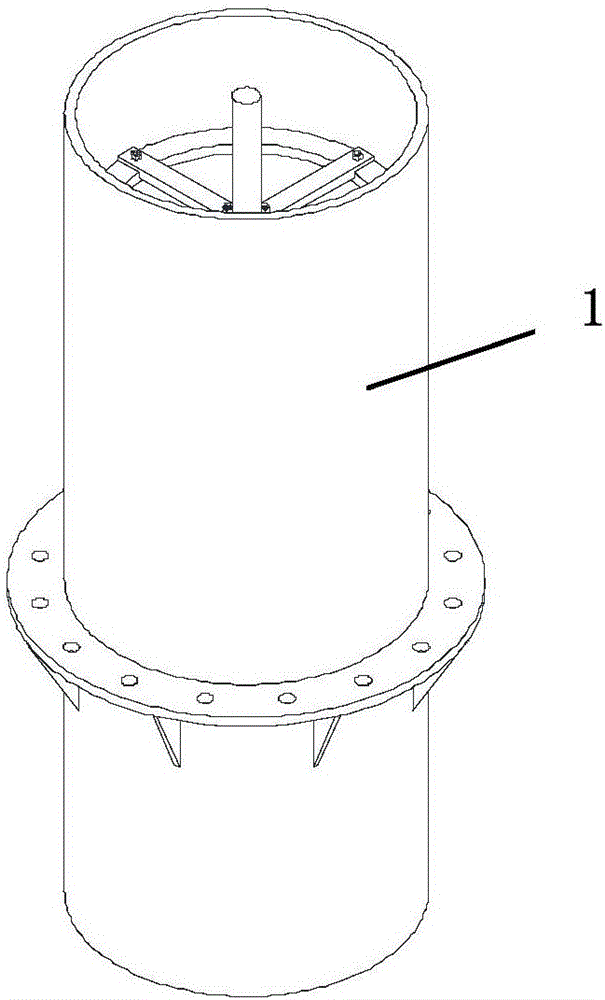

[0018] combine Figure 1~6 , an underwater explosion pressure measurement device based on an improved Hopkinson rod, its test environment, specific structure, measurement process and measurement method are as follows:

[0019] 1. Test use environment

[0020] The use environment of the present invention is as Figure 6 As shown, in addition to the main body of the present invention-the underwater explosion pressure measuring device 1 , the test auxiliary system includes a light source 5 , a cement pouring base 2 , a high-speed camera 4 , a small water tank 3 , and a data acquisition system 6 .

[0021] The underwater explosion pressure measuring device 1 is fixed on the cement pouring base 2 by means of bolt connection. The cement pouring base 2 has the characteristics of low cost and firm structure, and provides support for the und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com