Waste heat recovery steam production quality improving equipment applicable to industrial enterprises

A waste heat recovery and enterprise technology, applied in lighting and heating equipment, energy industry, steam boilers, etc., can solve the problem of unstable output of waste heat recovery steam turbine generator sets, unstable steam production flow of waste heat recovery, and low effective utilization rate of equipment, etc. problems, to achieve the effect of compact structure, short start-up time, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

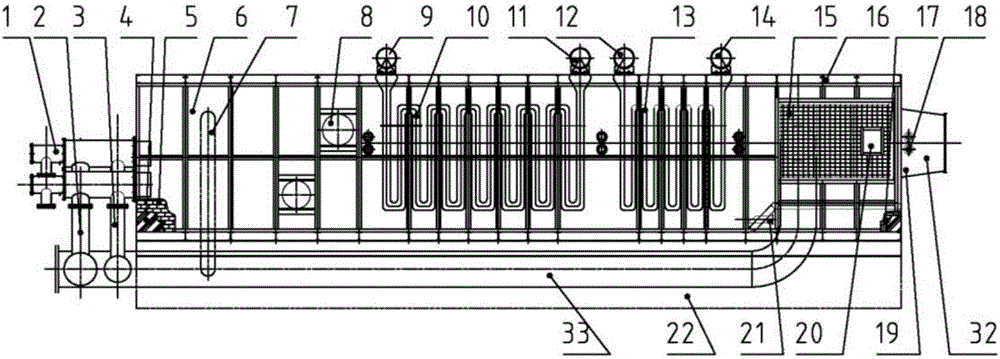

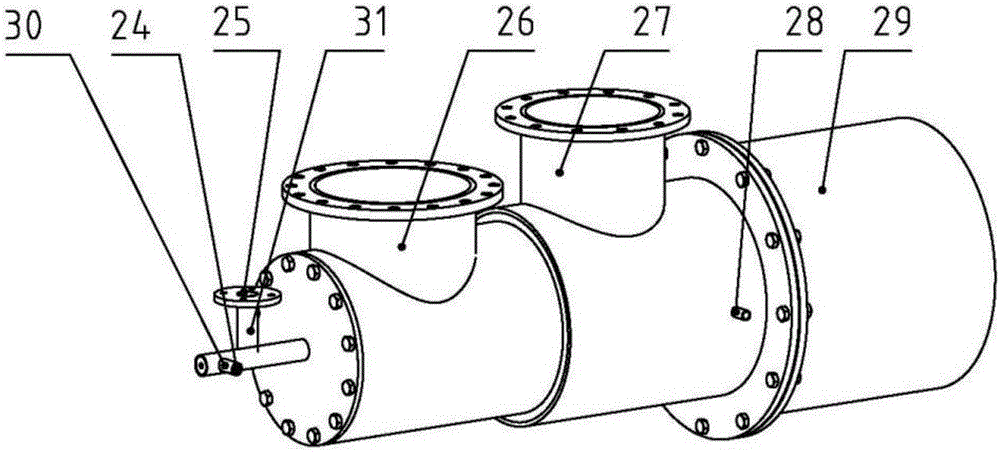

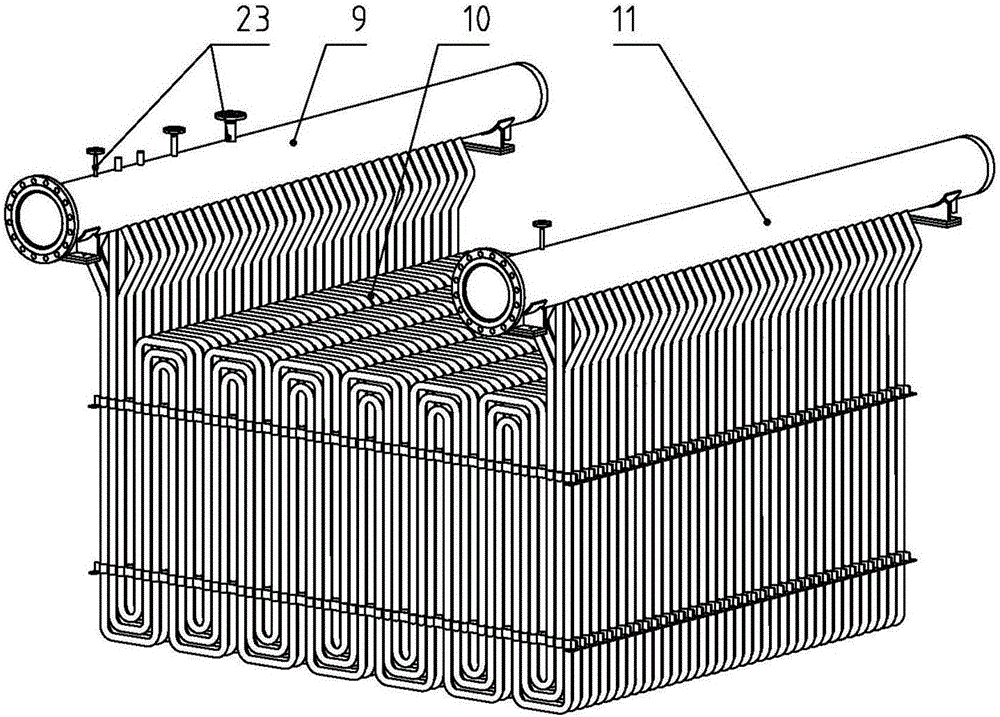

[0025] The present invention is applicable to waste heat recovery steam production quality improvement equipment of industrial enterprises, and its structure is as follows figure 1 As shown, a steel structure body 16 is included. The steel structure body 16 is mainly composed of I-shaped steel, channel steel, angle steel and steel plates through welding. One end of the steel structure body is connected with a combustion-supporting air pipeline 3. The combustion-supporting air pipeline 3 Together with the auxiliary fuel pipeline 2, it is connected to the burner 1, and the other end of the steel structure body opposite to this end is connected with a chimney connecting pipe 32; The refractory brick 5 is covered with an outer guard plate 4, and the refractory brick 5 is used for heat insulation protection of the equipment. The chamber surrounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com