Preparation method for non-ferromagnetism cubic-texture nickel-tungsten alloy base band

A nickel-tungsten alloy, cubic texture technology, applied in metal material coating process, solid-state diffusion coating, coating and other directions, can solve the problems of not being a high-performance superconducting tape, difficult to prepare, and low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The steps of the preparation method of the embodiment of the present invention 1 are as follows:

[0031] The nickel block and the tungsten block are proportioned according to the atomic percentage of tungsten being 5%, and the mixed material after the proportioning is placed in a vacuum induction melting furnace for melting to obtain a Ni-5at.%W alloy ingot, and the obtained Ni-5at.%W alloy ingots are forged and hot-rolled to obtain initial alloy ingots;

[0032] Using mechanical polishing, the surface of the initial alloy ingot obtained above is polished, the scale is removed, polished to a high finish, and then cold-rolled to a thickness of 50 μm, with a total deformation of 90%, to obtain a nickel-tungsten alloy cold-rolled base strip;

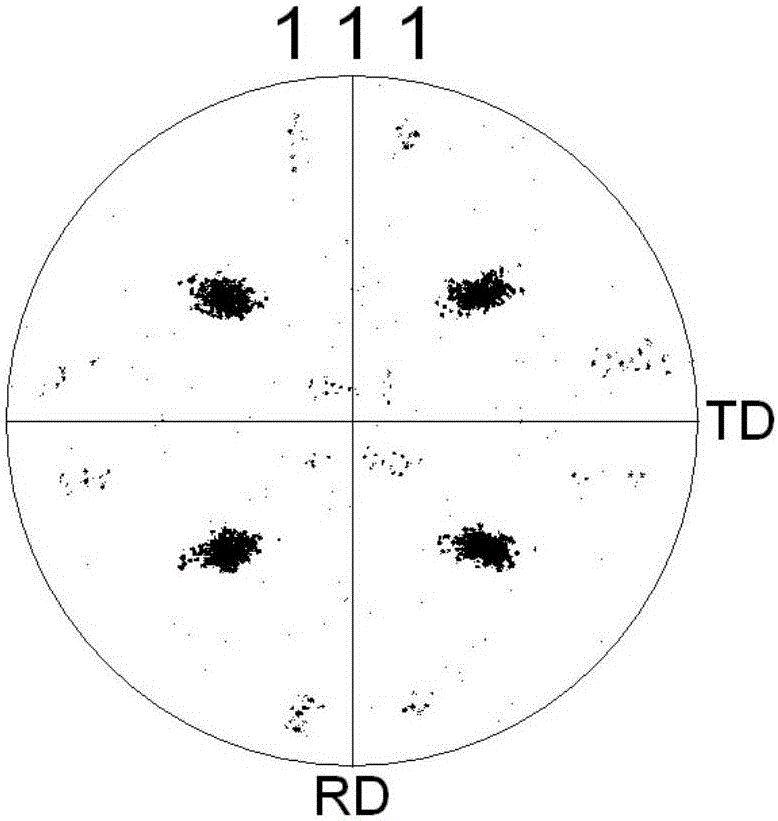

[0033] The obtained cold-rolled alloy base strip is subjected to recrystallization heat treatment to obtain a nickel-tungsten alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1000°C for 0....

Embodiment 2

[0037] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0038] The nickel block and the tungsten block are proportioned according to the atomic percentage of tungsten being 5%, and the mixed material after the proportioning is placed in a vacuum induction melting furnace for melting to obtain a Ni-5at.%W alloy ingot, and the obtained Ni-5at.%W alloy ingots are forged and hot-rolled to obtain initial alloy ingots;

[0039] Using mechanical polishing, carry out surface polishing on the initial alloy billet obtained above, remove scale, polish to high finish, then cold-roll to 70 μ m thick, total deformation is 90%, obtain nickel-tungsten alloy cold-rolled base strip;

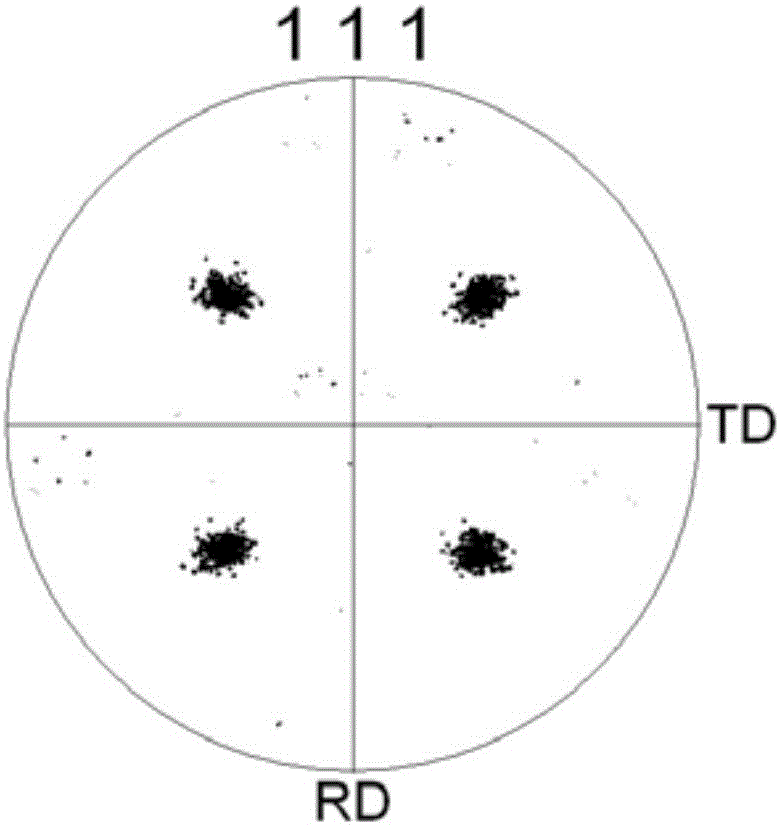

[0040] The obtained cold-rolled alloy base strip is subjected to recrystallization heat treatment to obtain a nickel-tungsten alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1050°C for 0.5 hours, and the heating rate is ...

Embodiment 3

[0044] The steps of the preparation method of the embodiment of the present invention 3 are as follows:

[0045] The nickel block and the tungsten block are proportioned according to the atomic percentage of tungsten being 5%, and the mixed material after the proportioning is placed in a vacuum induction melting furnace for melting to obtain a Ni-5at.%W alloy ingot, and the obtained Ni-5at.%W alloy ingots are forged and hot-rolled to obtain initial alloy ingots;

[0046] Using mechanical polishing, the surface of the initial alloy ingot obtained above is polished, the scale is removed, polished to a high degree of smoothness, and then cold rolled to a thickness of 75 μm, with a total deformation of 90%, to obtain a nickel-tungsten alloy cold-rolled base strip;

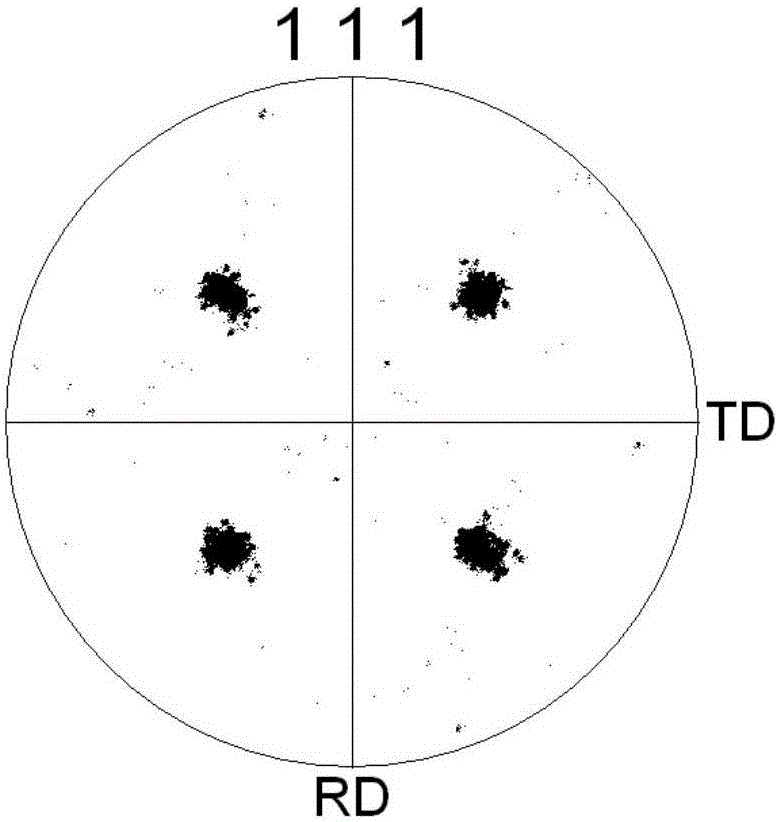

[0047] The obtained cold-rolled alloy base strip is subjected to recrystallization heat treatment to obtain a nickel-tungsten alloy base strip with strong cubic texture. The recrystallization heat treatment process is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com