Enzymatic hydrolysis alpha-lactalbumin polypeptide and enzymatic hydrolysis alpha-lactalbumin polypeptide nano micelle and preparation thereof

A lactalbumin and nano-micelle technology, which is applied in the field of enzymatic hydrolysis of α-lactalbumin polypeptide and nano-micelle of α-lactalbumin polypeptide, which can solve the problems of toxicity, large micelle particle size, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention further relates to a preparation method of loaded enzymatically hydrolyzed α-lactalbumin polypeptide nanomicelles, which comprises:

[0061] Step A, mixing the hydrophobic substance solution with the above-mentioned enzymatic α-lactalbumin polypeptide or the enzymatic α-lactalbumin polypeptide solution prepared by the above method, and stirring evenly to make loaded enzymatic α-lactalbumin polypeptide nanomicelles Base fluid;

[0062] Step B, the loaded enzymatically hydrolyzed α-lactalbumin polypeptide nano-micelle base solution is reacted at room temperature for 30-60 minutes, preferably 30-40 minutes, and more preferably after 30 minutes, to prepare the loaded enzymatically hydrolyzed α-lactalbumin polypeptide nano micelles;

[0063] Wherein, in the loaded enzymatically hydrolyzed α-lactalbumin polypeptide nanomicelle base fluid, the mass ratio of the hydrophobic substance to the enzymolyzed α-lactalbumin polypeptide is (1-3):5.

[0064] In on...

Embodiment 1

[0082] Example 1: Preparation of enzymatically hydrolyzed α-lactalbumin polypeptide.

[0083] 1) Accurately weigh 6 mg of α-lactalbumin into a 1.5 mL centrifuge tube, add 200 μL of pH=7.5, 75 mM Tris-HCl buffer solution, after dissolving, add 1.2 μL of proteolytic enzyme;

[0084] 2) Draw up the solution with a 2mL syringe, and filter the solution once with a 0.2 μm polyethersulfone syringe filter;

[0085] 3) Heat in a water bath at 50°C for 17 minutes, centrifuge and take the supernatant;

[0086] 4) Freeze-drying the supernatant to obtain the enzymatically hydrolyzed polypeptide.

[0087] After detection, the molecular weight of the enzymatically hydrolyzed α-lactalbumin polypeptide is 9.9-11KDa.

Embodiment 2

[0088] Example 2: Preparation of enzymatically hydrolyzed α-lactalbumin polypeptide nanomicelles.

[0089] 1) Accurately weigh 5 mg of the polypeptide and dissolve it in 5 mL of pH=7.5, 75 mM Tris-HCl buffer;

[0090] 2) Rotate and mix for 30 minutes at a speed of 20 rpm to obtain blank polypeptide nanomicelles.

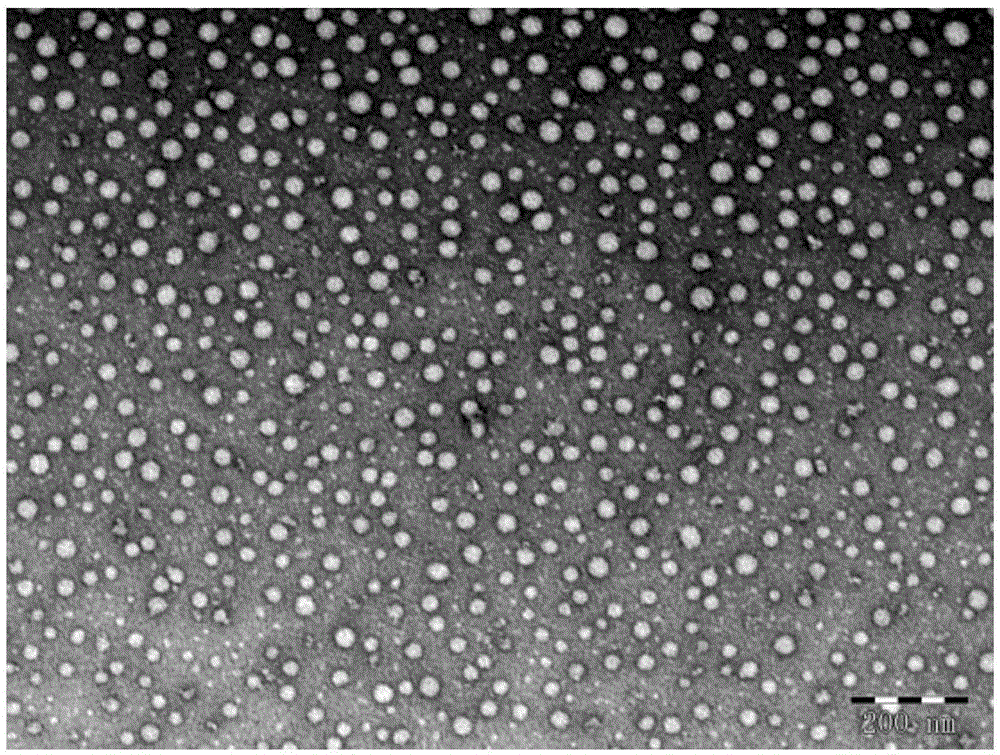

[0091] Observation of these blank polypeptide nanomicelles with a transmission electron microscope, the results are as follows figure 1 shown. from figure 1 It can be seen that the enzymatic hydrolyzed α-lactalbumin polypeptide nano-micelle of the present invention has a small particle size of about 20nm and good dispersibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com