Transgenic engineering saccharomyces cerevisiae SF4 for efficiently fermenting ethanol using xylose

A technology of transgenic engineering and Saccharomyces cerevisiae, which is applied in the field of genetically engineered Saccharomyces cerevisiae SF4, can solve the problems of low ethanol yield, low tolerance to high-concentration sugar, low tolerance to ethanol and fermentation inhibitors, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

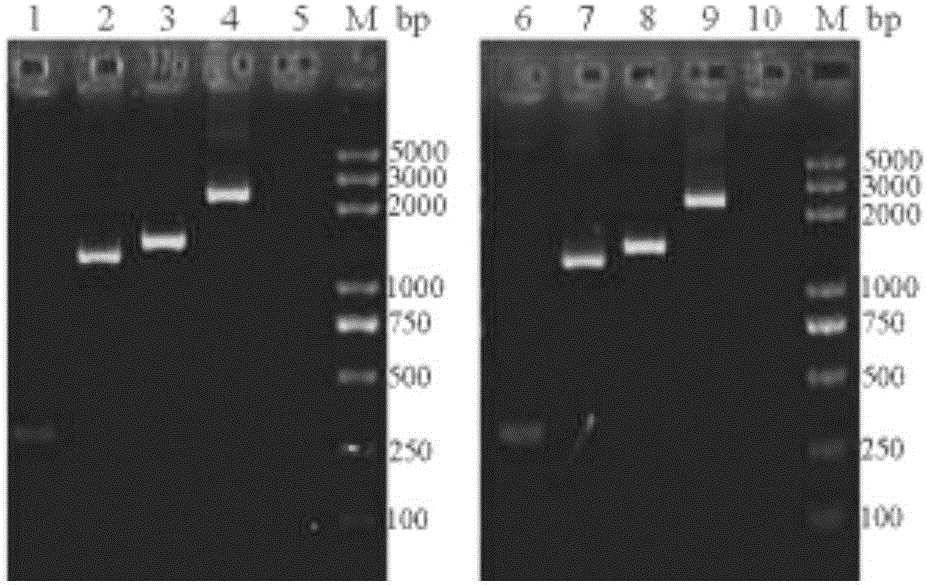

[0060] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0061]1. Application steps of Saccharomyces cerevisiae SF4

[0062] SF4→glycerol tube preservation of strains→YPD medium (2% glucose, 1% yeast extract, 2% peptone, 0.03 g adenine, 2% agar for solids) slope activation→YPD medium liquid triangular flask seeds→according to 0.1 Add ~0.5% of the amount into the straw hydrolyzate or xylose solution → static fermentation for 48-72 hours → distillation of the fermented liquid at 80-100°C → cooling to obtain ethanol.

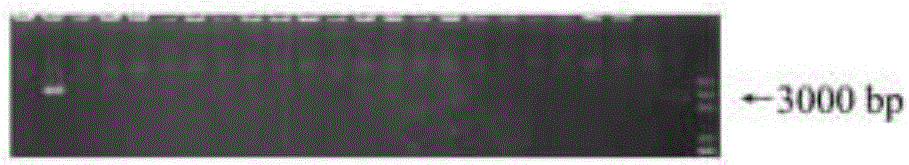

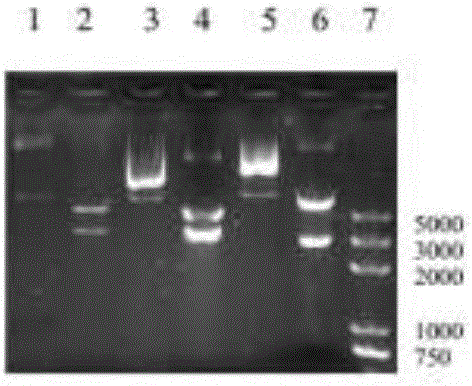

[0063] 2. Methods and technical routes for the construction and verification of recombinant strains

[0064] The sequence listing shows that SF4 contains xyl1-(G 4 S 1 ) 3 - Nucleotide sequence of xyl2 gene (SEQ ID NO: 5).

[0065] 1. Construction of SF4 and verification of its functions

[0066] 1) pYPGE15XYL1-(G 4 S 1 ) 1 -XYL2 vector construction

[0067] Since the construction of this fusion protein needs to add a seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com