Soilless polyether amine alkyl glucoside drilling fluid and preparation method thereof

A technology of ether amino alkyl glycoside drilling and polyether amino alkyl glycoside, which is applied in the field of soil-free polyether amino alkyl glycoside drilling fluid and its preparation, can solve the problems of poor suppression performance and reservoir protection, etc. Achieve the effects of good suppression performance, good suppression performance and good reservoir protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention provides a kind of preparation method of soil-free polyether amino alkyl glycoside drilling fluid described in the above technical scheme, comprising:

[0081] Mix polyether amino alkyl glycoside, viscosifier, fluid loss reducer, plugging agent, pH regulator, carbonate, sodium chloride, sulfur-containing antioxidant and water, and then perform aging treatment to obtain no Earth phase polyether amino alkyl glycoside drilling fluid.

[0082] In the present invention, the types of polyether amino alkyl glycosides, viscosifiers, fluid loss control agents, plugging agents, pH regulators, carbonates, sodium chloride, sulfur-containing antioxidants and water , source and dosage are the same as polyetheramino alkyl glycosides, viscosifiers, fluid loss reducers, plugging agents, pH regulators, carbonates, sodium chloride, sulfur-containing antioxidants and The type, source and amount of water are the same, and will not be repeated here.

[0083] In an emb...

Embodiment 1

[0110] Add 44.05g of ethylene oxide, 97g of methyl glucoside, 72g of distilled water and 1.72g of p-toluenesulfonic acid into a high-pressure reactor equipped with a thermometer, a condenser, and a stirrer, and react at 3MPa and 50°C for 0.5 hour, the intermediate product was obtained;

[0111] Neutralize the intermediate product with the neutralizing agent NaOH to a pH value of 6, add 24g of ethylenediamine, react at a temperature of 40°C under normal pressure for 3 hours, remove water from the obtained reaction product to obtain polyetheramine methyl glucoside.

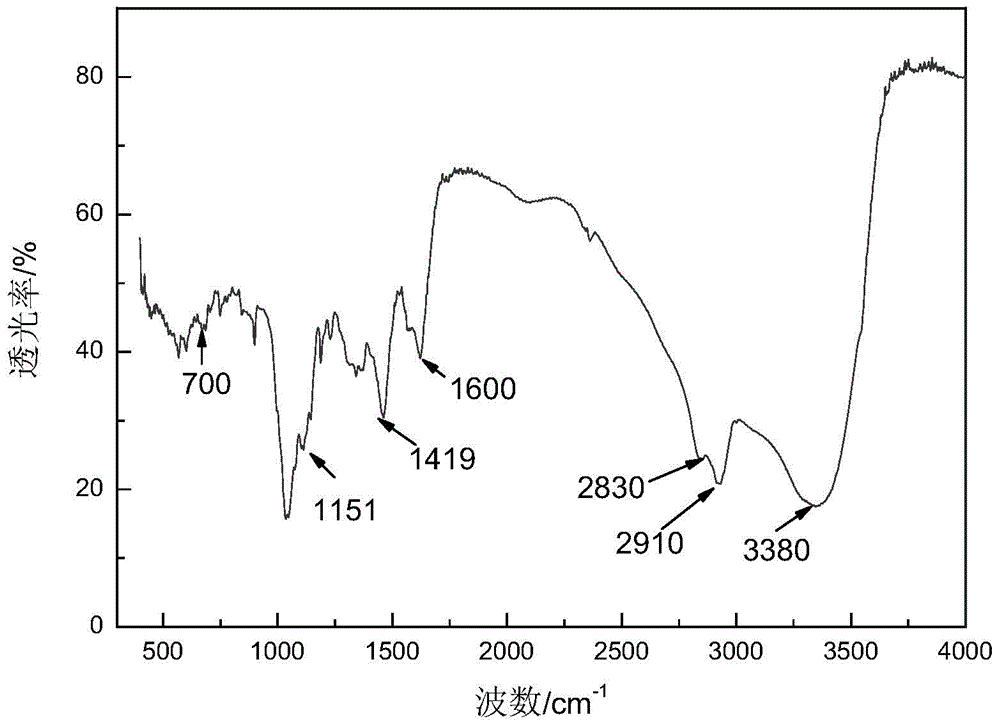

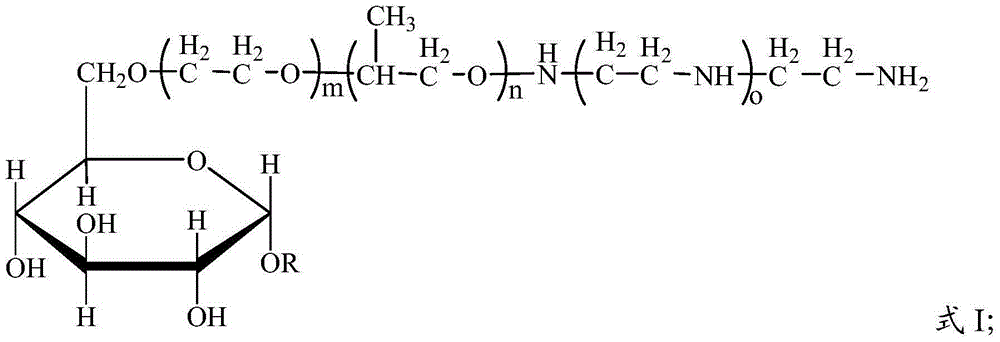

[0112] The polyetheraminomethyl glucoside prepared in Example 1 of the present invention was carried out infrared detection, and the detection results were as follows: figure 1 as shown, figure 1 For the infrared spectrogram of the polyether aminomethyl glycoside prepared in Example 1 of the present invention, by figure 1 It can be seen that the polyether aminomethyl glycoside prepared in Example 1 of the present...

Embodiment 2

[0116] Add 44.05g of ethylene oxide, 104g of ethyl glucoside, 90g of distilled water and 1.96g of sulfuric acid into a high-pressure reactor equipped with a thermometer, condenser, and stirrer, and react at 4MPa and 60°C for 1 hour to obtain mid product;

[0117] The intermediate product was neutralized with a neutralizing agent NaOH to a pH value of 6, 51.59 g of diethylenetriamine was added, and the temperature was 50° C. under normal pressure to react for 4 hours, and the obtained reaction product was dehydrated to obtain a poly Etheraminoethyl Glycoside.

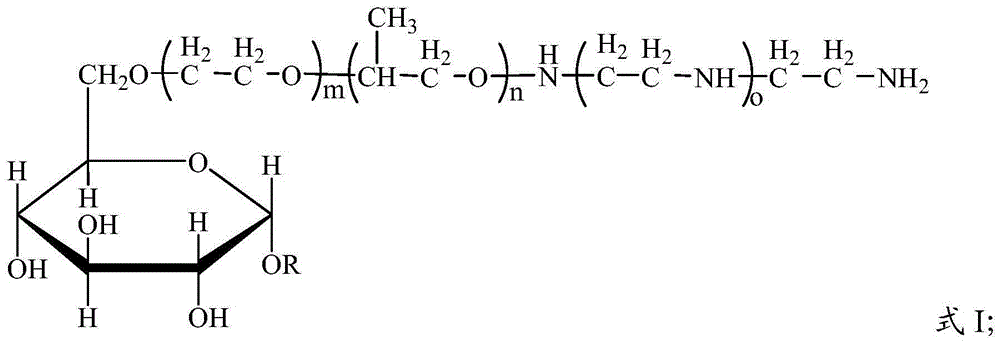

[0118] The polyetheraminoethyl glycoside prepared in Example 2 of the present invention was subjected to infrared detection, and the detection result was that the polyetheraminoethyl glycoside prepared in Example 2 of the present invention had a structure shown in formula 2:

[0119]

[0120] In formula 2, m is 0-3, and o is 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

| Dynamic shear force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com