BMW grey finishing coat for motorcycle fuel tank

A technology of motorcycles and BMW, applied in the field of coatings, can solve the problems of high cost of motorcycle topcoats and affect consumer acceptance, and achieve the effect of good effect, guarantee of excellence, stability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

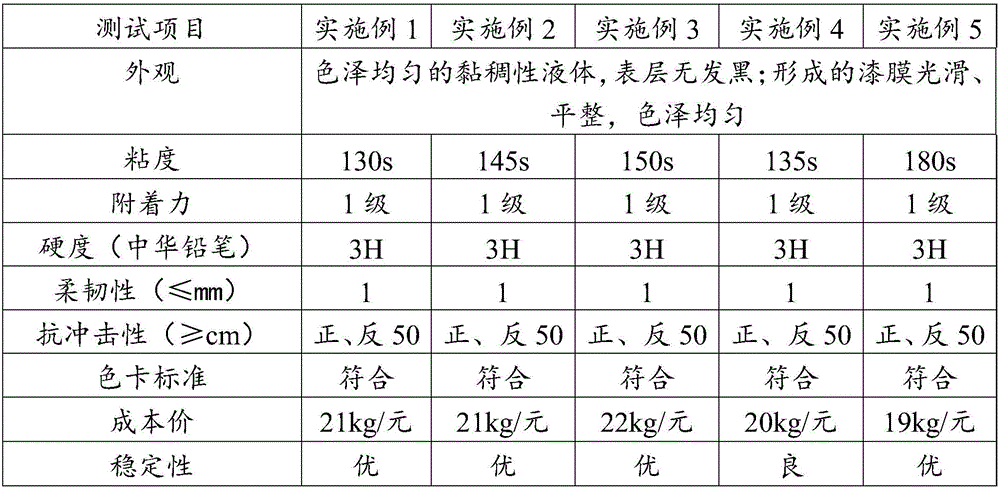

Examples

preparation example Construction

[0027] The present invention is described in detail as follows: a BMW gray topcoat for motorcycle fuel tanks, composed of A component and B component, the mass ratio of the A component to the B component is (10-20): 1, the described Component A includes the following components in parts by weight: pearl powder: 3-8 parts; iron red: 1-2 parts; aluminum silver paste: 1.5-2.5 parts; diluent: 10-20 parts; -85 parts; anti-settling agent: 0.1-1 part; leveling agent: 0.5-1.5 parts; the B component is a polyurethane curing agent; the preparation method of the BMW gray topcoat for the motorcycle oil tank includes the following steps :

[0028] 1) Add the acrylic resin and anti-sedimentation agent in the formulated amount into the disperser, and then stir at a high speed of 1000-3000r / min for 5-10min to obtain the base material;

[0029] 2) Add the formulated amount of aluminum silver paste, iron red, pearl powder, diluent and leveling agent into the stirring tank in sequence, and stir...

Embodiment 1

[0041] A BMW gray topcoat for a motorcycle oil tank, consisting of A component and B component, the mass ratio of the A component to the B component is 20:1, and the A component includes the following components in parts by weight: Pearlescent powder: 3 parts; Iron red: 1 part; Aluminum silver paste: 1.5 parts; Thinner: 15 parts; Hydroxy acrylic resin: 80 parts; Anti-settling agent: 0.5 parts; BASF 190 curing agent; the preparation method of the BMW gray topcoat for the motorcycle fuel tank comprises the steps:

[0042] 1) Add 80 parts of acrylic resin and 0.5 parts of anti-settling agent into the disperser, then stir at a high speed of 1000-3000r / min for 5-10min to obtain the base material;

[0043] 2) Add 1.5 parts of aluminum silver paste, 1 part of iron red, 3 parts of pearl powder, 15 parts of diluent and 0.5 parts of leveling agent into the stirring tank in sequence, and stir for 15-30 minutes at a speed of 20r / min-200r / min , to obtain mixed pigments and fillers;

[00...

Embodiment 2

[0048] A BMW gray finish paint for motorcycle oil tanks, composed of A component and B component, the mass ratio of the A component to the B component is 15:1, and the A component includes the following groups in parts by weight Points: pearl powder: 5 parts; iron red: 1.5 parts; aluminum silver paste: 2 parts; thinner: 15.5 parts; hydroxyacrylic resin: 75 parts; anti-settling agent: 0.5 parts; B component is polyurethane solidifying agent; The preparation method of BMW gray topcoat for described motorcycle fuel tank comprises the steps:

[0049] 1) Add 75 parts of acrylic resin and 0.5 part of anti-settling agent into the disperser, then stir at a high speed of 1000-3000r / min for 5-10min to obtain the base material;

[0050] 2) Add 2 parts of aluminum silver paste, 1.5 parts of iron red, 5 parts of pearl powder, 15.5 parts of diluent and 1 part of leveling agent into the stirring tank in sequence, and stir for 15-30min at the speed of 20r / min-200r / min , to obtain mixed pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com