Hydrotalcite-intercalated flame-retarding-enhanced polypropylene material and preparing method thereof

A polypropylene material and hydrotalcite technology are applied in the field of hydrotalcite intercalation flame retardant reinforced polypropylene material and its preparation, which can solve the problems of poor flame retardant performance, poor thermal stability and low strength, achieve excellent flame retardant performance, improve Strength, the effect of increasing the interfacial interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

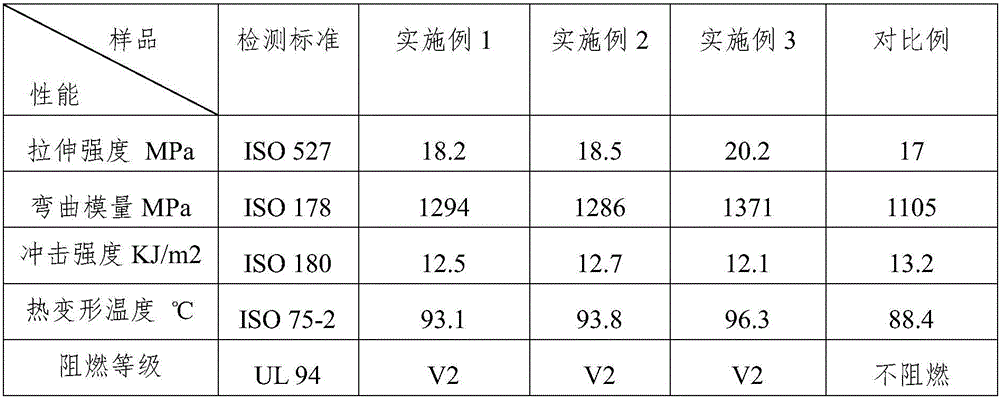

Embodiment 1

[0033] In this example, the hydrotalcite intercalated flame-retardant reinforced polypropylene material is made of the following raw materials in parts by weight: 70 parts of short-chain copolymerized polypropylene, 0.1 part of light stabilizer, 0.3 part of calcium stearate, 10 parts of modified hydrotalcite, Maleic anhydride-styrene co-grafted polypropylene 4 parts, antioxidant 0.2 part; Wherein light stabilizer is light stabilizer 531, antioxidant is antioxidant DSTP;

[0034] Wherein the preparation method of modified hydrotalcite comprises the following steps:

[0035] S1. Put 3g of hydrotalcite and 200mL of absolute ethanol in a 1000mL three-necked flask, and place the three-necked flask in a 65°C water bath and stir for 0.5h;

[0036] S2. Dissolve 4g of itaconic acid in deionized water at 40°C and pour it into the three-necked flask of step S1, adjust the solution to pH 4 with dilute nitric acid with a pH of about 2, then stir for 7 hours, cool, filter, and then use 50 ...

Embodiment 2

[0042] The hydrotalcite intercalated flame-retardant reinforced polypropylene material in this example is made of the following raw materials in parts by weight: 80 parts of short-chain copolymerized polypropylene, 0.4 part of light stabilizer, 0.6 part of ethylene bisstearamide, and 15 parts of modified hydrotalcite 8 parts, 8 parts of maleic anhydride grafted polypropylene, 0.5 part of calcium stearate, 3 parts of titanate; wherein the light stabilizer is light stabilizer UV-TBS, and the antioxidant is antioxidant 626;

[0043] Wherein the preparation method of modified hydrotalcite comprises the following steps:

[0044] S1. Put 4g of hydrotalcite and 250mL of absolute ethanol in a 1000mL three-necked flask, and place the three-necked flask in a 70°C water bath and stir for 15 hours;

[0045]S2. Dissolve 5g of sodium dodecylsulfonate in deionized water at 40°C and pour it into the three-necked flask of step S1, adjust the solution to pH 4 with dilute nitric acid with a pH o...

Embodiment 3

[0051] In this embodiment, the hydrotalcite intercalated flame-retardant reinforced polypropylene material is made of the following raw materials in parts by weight: 80 parts of short-chain copolymerized polypropylene, 0.2 part of light stabilizer, 0.3 part of calcium stearate, 10 parts of modified hydrotalcite, 8 parts of maleic anhydride-styrene co-grafted polypropylene, 0-3 parts of titanate; wherein the light stabilizer is light stabilizer 326 and antioxidant 1076;

[0052] Wherein the preparation method of modified hydrotalcite comprises the following steps:

[0053] S1. Put 3 g of hydrotalcite and 250 mL of absolute ethanol in a 1000 mL three-necked flask, and place the three-necked flask in a water bath at 70°C for 15 hours;

[0054] S2. Mix 3 g of itaconic acid and 3 g of sodium dodecylsulfonate, dissolve it in deionized water at 40° C. and pour it into the three-necked flask of step S1, adjust the solution to pH 4 with dilute nitric acid with a pH of about 2, Stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com