Ternary lamellar ceramic titanium silicon carbide and metallic nickel diffusion bonding method

A ternary layered, diffusion connection technology, applied in the field of ceramic and metal connection, can solve the problem of few ceramic research, achieve good mechanical properties, expand the scope of application, and achieve good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

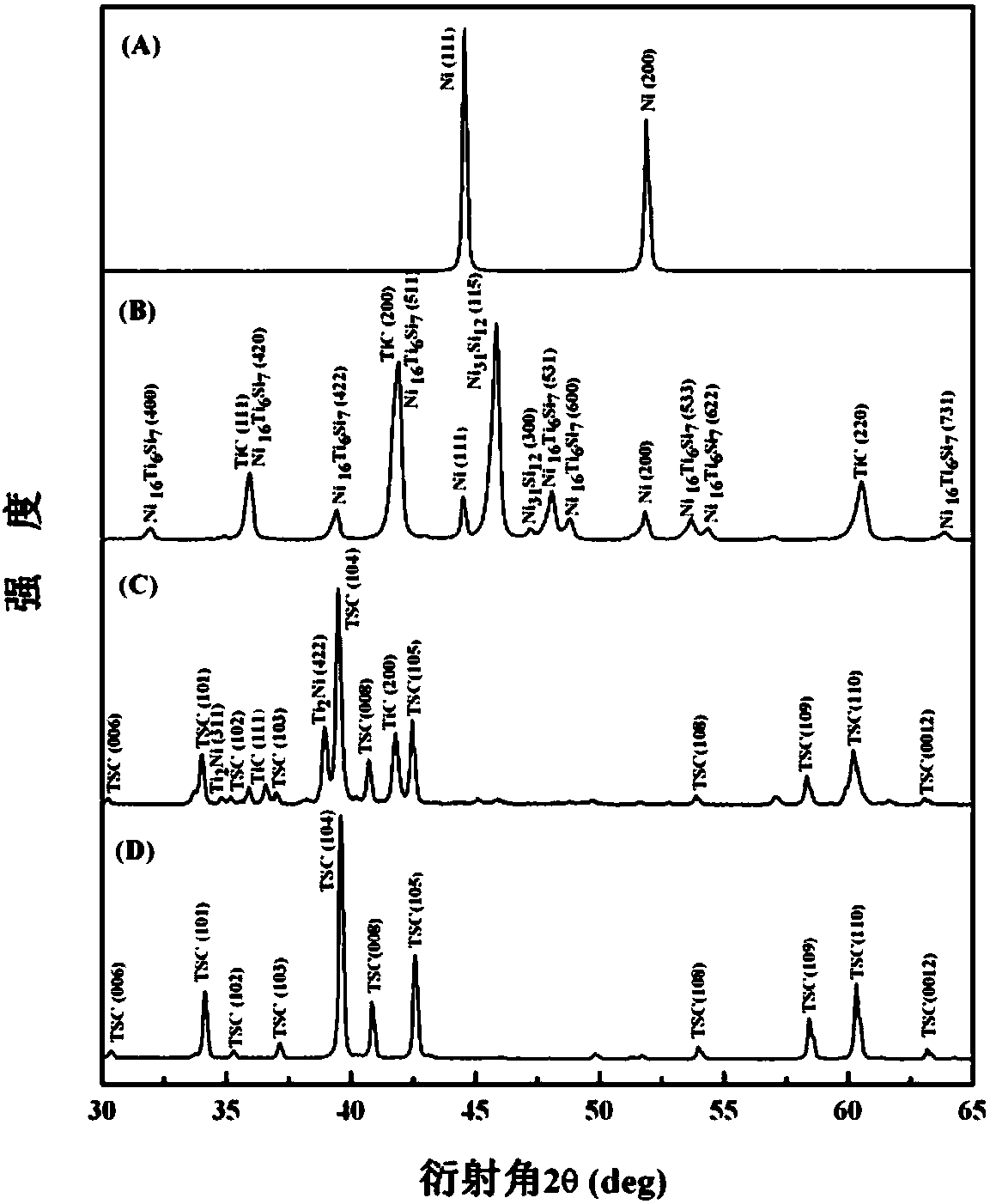

[0013] Embodiment 1: with Ti 3 SiC 2 Ceramic and metallic nickel for surface treatment, Ti 3 SiC 2 Ceramic and metallic nickel are ground, polished, and ultrasonically cleaned. Then the processed Ti 3 SiC 2 Ceramic and metal nickel are installed in a hot-press furnace and vacuumized; when the vacuum reaches 5×10 -2 Heating starts at Pa. At a temperature of 800°C, a pressure of 10MPa, and constant pressure for 90min, Ni and Ti were diffusely bonded. 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, the temperature of the hot-press furnace is slowly lowered under the original vacuum condition, first to 400°C at a rate of 5°C / min, and then to 200°C at a rate of 10°C / min, then stop vacuuming and remove the pressure. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines.

Embodiment 2

[0014] Embodiment 2: with Ti 3 SiC 2 Ceramic and metallic nickel for surface treatment, Ti 3 SiC 2 Ceramic and metallic nickel are ground, polished, and ultrasonically cleaned. Then the processed Ti 3 SiC 2 Ceramic and metal nickel are installed in a hot-press furnace and vacuumized; when the vacuum reaches 5×10 -2 Heating starts at Pa. At a temperature of 900°C, a pressure of 20 MPa, and constant pressure for 30 minutes, Ni and Ti were diffusely bonded. 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, the temperature of the hot-press furnace is slowly lowered under the original vacuum condition, first to 400°C at a rate of 5°C / min, and then to 200°C at a rate of 10°C / min, then stop vacuuming and remove the pressure. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines. The joint shear streng...

Embodiment 3

[0015] Embodiment 3: test piece is carried out surface treatment, Ti 3 SiC 2 Ceramic and metallic nickel are ground, polished, and ultrasonically cleaned. Then install the processed weldment in a hot-press furnace and vacuumize it; when the vacuum degree reaches 5×10 -2 Heating starts at Pa. At a temperature of 1000°C, a pressure of 20MPa, and constant pressure for 10 minutes, Ni and Ti were diffusely bonded. 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, the temperature of the hot-press furnace is slowly lowered under the original vacuum condition, first to 400°C at a rate of 5°C / min, and then to 200°C at a rate of 10°C / min, then stop vacuuming and remove the pressure. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines. The joint shear strength reaches 121MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com