A kind of sleeve grouting material for prefabricated building reinforcement connection

A technology for sleeve grouting and building steel bars, which is applied in the field of sleeve grouting materials, can solve the problems of small water consumption bandwidth, uneven quality, insufficient strength, etc., and achieve good initial fluidity, improved mechanical properties, and excellent early strength performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

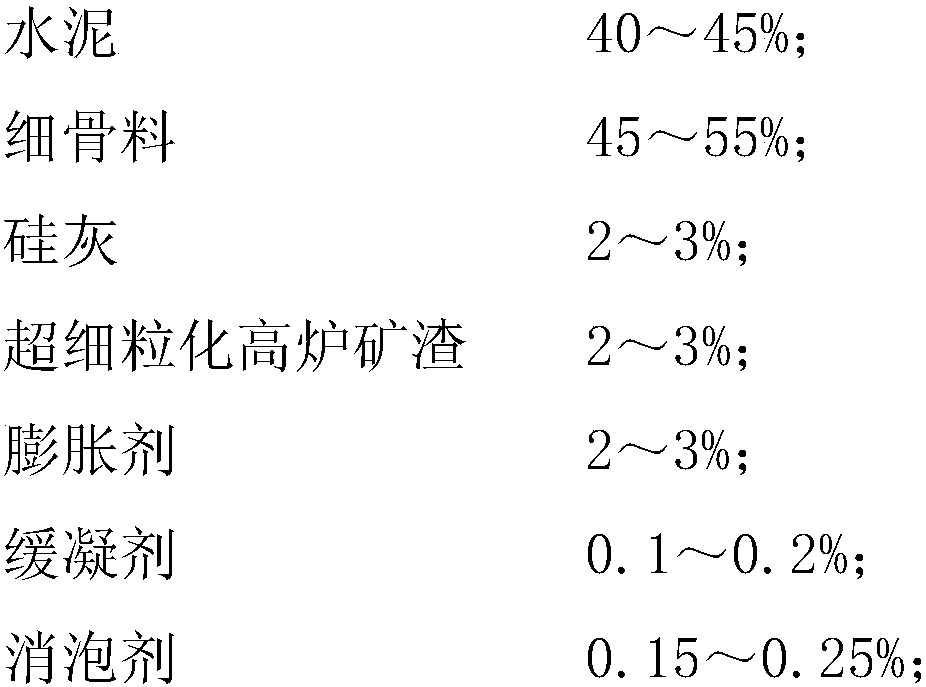

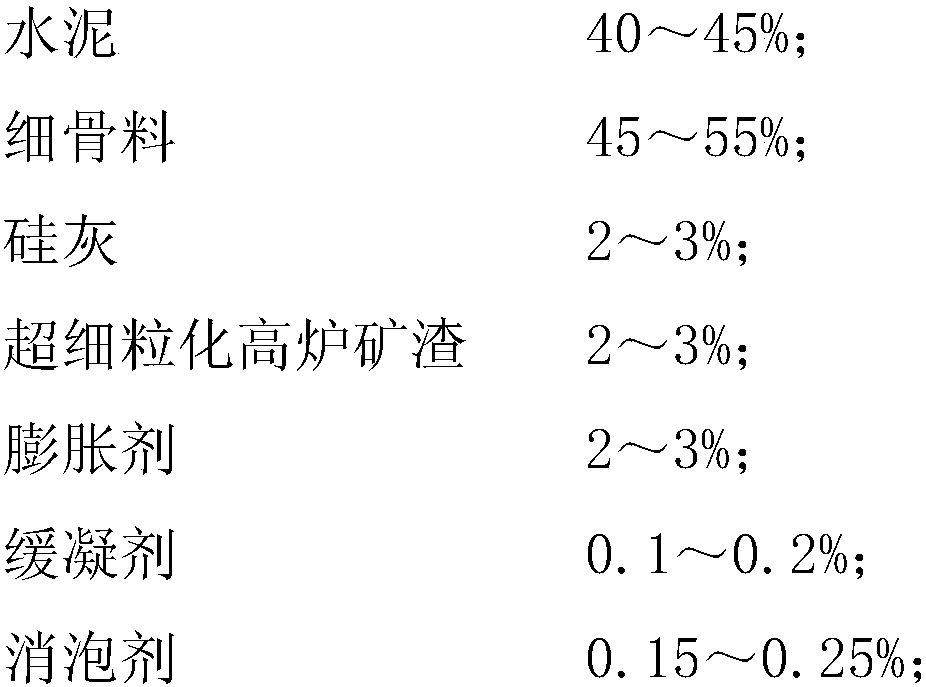

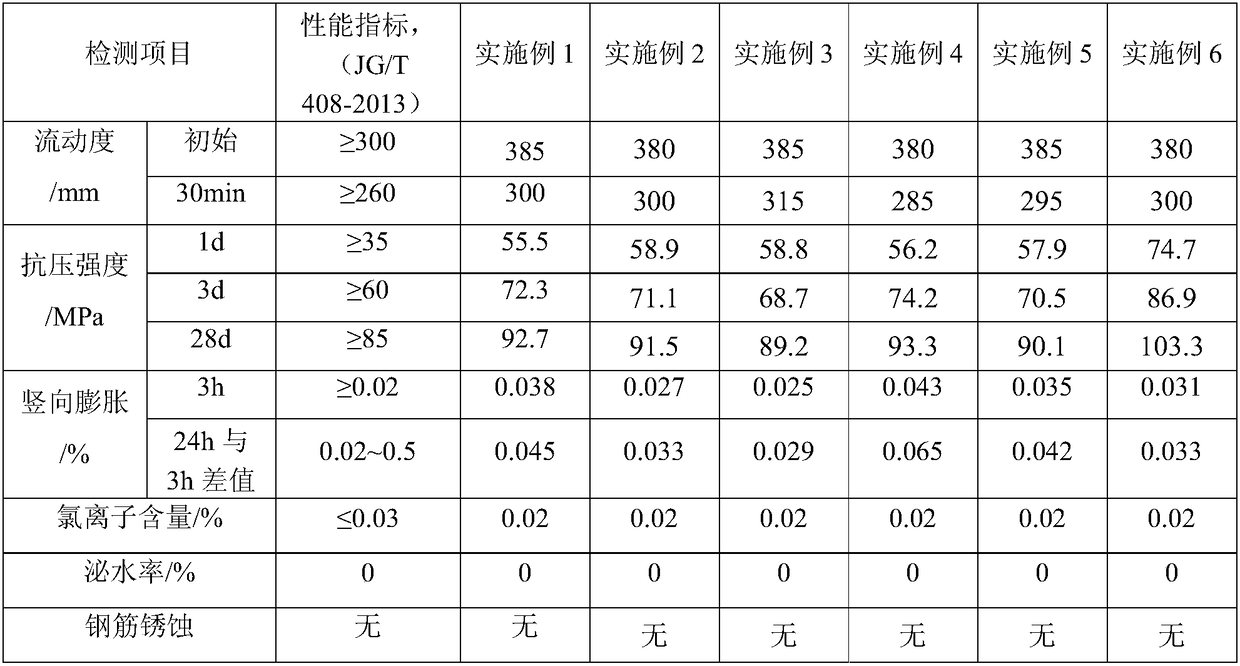

Embodiment 1

[0034] The sleeve grouting material used for steel bar connection in this embodiment is made by mixing grouting material dry powder with water and water reducing agent. The grouting material dry powder is mixed with the following components, and each component is composed as follows according to mass percentage : Cement (the mass ratio of sulphoaluminate cement to Portland cement is 8:92) 42.1%, fine aggregate (quartz sand) 50%, silica fume 2.5%, superfine granulated blast furnace slag 2.5%, expansion agent 2.5%, retarder 0.15%, defoamer 0.25%; water-to-cement ratio 0.25, water-reducing agent mixed with 3.0% of the total amount of cementitious material.

[0035] Mix each component according to the ratio, and use a mortar mixer to stir for 4 to 5 minutes to prepare the grouting material.

Embodiment 2

[0037] The sleeve grouting material used for steel bar connection in this embodiment is made by mixing grouting material dry powder with water and water reducing agent. The grouting material dry powder is mixed with the following components, and each component is composed as follows according to mass percentage : Cement (the mass ratio of sulphoaluminate cement to Portland cement is 7:93) 42.5%, fine aggregate (quartz sand) 50%, silica fume 3.0%, superfine granulated blast furnace slag 2.1%, expansion agent 2.0%, retarder 0.2%, defoamer 0.20%; water-to-cement ratio 0.25, water reducer mixed with 2.5% of the total amount of cementitious materials.

[0038] Mix each component according to the ratio, and use a mortar mixer to stir for 4 to 5 minutes to prepare the grouting material.

Embodiment 3

[0040] The sleeve grouting material used for steel bar connection in this embodiment is made by mixing grouting material dry powder with water and water reducing agent. The grouting material dry powder is mixed with the following components, and each component is composed as follows according to mass percentage : Cement (the mass ratio of sulfoaluminate cement to Portland cement is 7:93) 42.5%, fine aggregate (quartz sand) 50%, silica fume 2.0%, superfine granulated blast furnace slag 2.5%, expansion agent 2.6%, retarder 0.15%, defoamer 0.25%; water-binder ratio 0.26, water-reducing agent mixed with 3.5% of the total cementitious material.

[0041] Mix each component according to the ratio, and use a mortar mixer to stir for 4 to 5 minutes to prepare the grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com