Method for treating industrial wastewater containing heavy metal contaminants by utilizing industrial fly ash and nano iron

A technology for industrial wastewater and fly ash, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of heavy metal dissolution, difficult recovery, and agglomeration, so as to reduce heavy metal dissolution and production Low cost and the effect of reducing agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

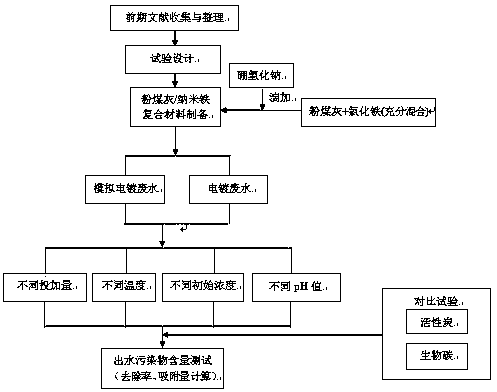

Method used

Image

Examples

Embodiment 1

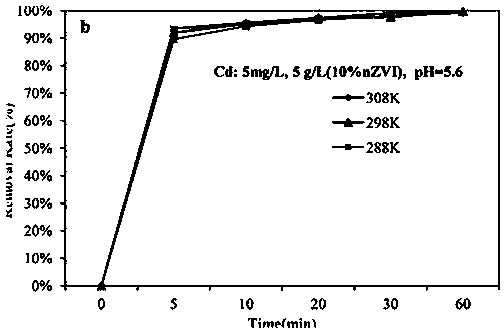

[0059] (1) First weigh a certain amount of industrial fly ash (grade I) at room temperature, soak the fly ash in water, add 10% ferric chloride (calculated as Fe) and mix thoroughly, then add borocyanide dropwise The amount of sodium chloride is 20.8g / (100g composite material) to reduce ferric ions to zero-valent nano-iron, and load it on the fly ash. Add fly ash-nano-iron composite material to industrial wastewater containing heavy metal pollutants such as cadmium, stir and fully react at room temperature, precipitate and separate after reacting for 5 minutes, and recover fly ash-nano-iron composite material, after precipitation The supernatant of the supernatant can meet the relevant comprehensive sewage discharge standards and be discharged directly; the weight ratio of fly ash and nano-zero-valent iron is 1:0.11; the particle size of industrial fly ash is 0.5-10 μm, and the nano-zero-valent iron Iron particle size 80~120 nm;

[0060] The content of nano-zero-valent iron a...

Embodiment 2

[0064] A method for treating industrial wastewater containing heavy metal pollutants using fly ash and nano-iron composite materials:

[0065] (1) First mix industrial fly ash and ferric chloride solution components at room temperature, and then dropwise add sodium borocyanide in the mixed solution at an amount of 20.8g / (100g composite material) to reduce ferric ions into nano Zero-valent iron is loaded onto the fly ash to obtain a fly ash-nanometer iron composite material; wherein the weight and number ratio of fly ash and nano-zero-valent iron is 1:0.11;

[0066] The particle size of the industrial fly ash is 0.5-10 μm, and the particle size of the nano-zero-valent iron is 80-120 nm;

[0067] (2) Then add industrial wastewater containing heavy metal pollutants (Pb and Zn) to the composite material for reaction, stir and fully react at room temperature, and let it stand for 5 minutes (~60 min) to obtain supernatant and sediment; The weight ratio of the material to the indust...

Embodiment 3

[0070] A method for treating industrial wastewater containing heavy metal pollutants using industrial fly ash and nano-iron composite materials:

[0071] (1) First mix industrial fly ash and ferric chloride solution components at room temperature, then add sodium borocyanide dropwise in the mixed solution to reduce ferric ions to nanometer zero-valent iron, and load them on fly ash , so as to obtain industrial fly ash-nano-iron composite material; wherein the mass ratio of industrial fly ash and nano-zero-valent iron is 1:0.22; the particle size of industrial fly-ash is 0.5-10 μm, and the nano-zero-valent iron particles The diameter is 80~120nm; the dosage of sodium borocyanide is 41.6g / (100g composite material.

[0072] (2) Then add industrial wastewater containing heavy metal pollutants (including Cd, Cr, Cu, Pb and Zn) to the composite material for reaction, stir and fully react at room temperature, and let it stand for 30 minutes to obtain supernatant and sediment ; where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com