Method for recovering organic solvent from maleic anhydride wastewater

A technology for organic solvents and wastewater, applied in chemical instruments and methods, water pollutants, extracted water/sewage treatment, etc., can solve the problems of difficult discharge standards, difficult treatment, and inapplicability, and improve biodegradability , Reduce solvent consumption and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

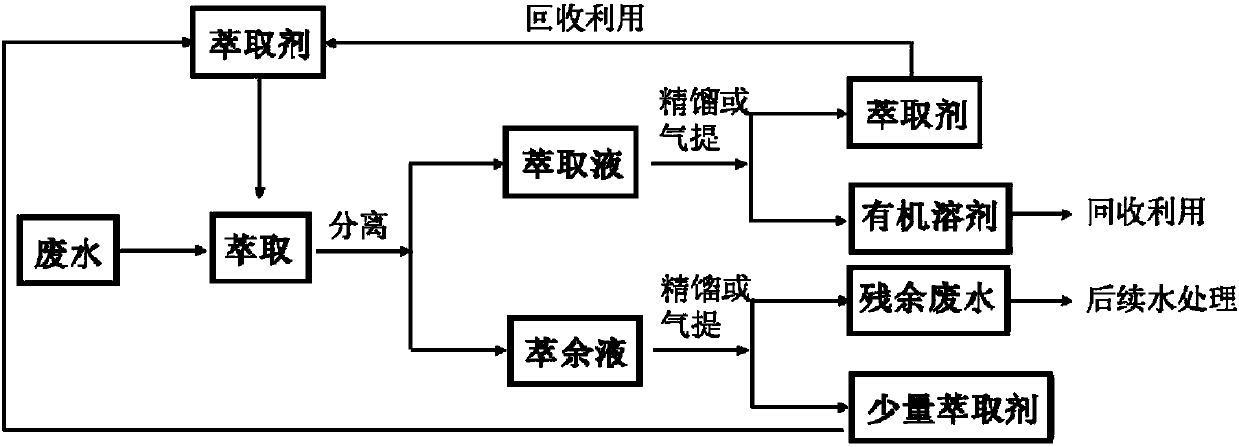

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a kind of method that reclaims organic solvent from maleic anhydride wastewater, comprises the steps:

[0043] S1: Mix 100mL maleic anhydride wastewater and 100mL dichloromethane evenly, place them in a separatory funnel, and let stand for extraction;

[0044] S2: After the layers are clearly separated, the two phases are separated with a separatory funnel to obtain the extract and raffinate;

[0045] S3: nitrogen bubbling is performed on the extract to separate the extractant dichloromethane from the organic solvent, wherein the separated organic solvent includes organic substances that are difficult to biodegrade such as DIBE, DBP and the like;

[0046] S21: The raffinate is bubbled with nitrogen, and the extractant is removed from the raffinate to obtain residual waste water.

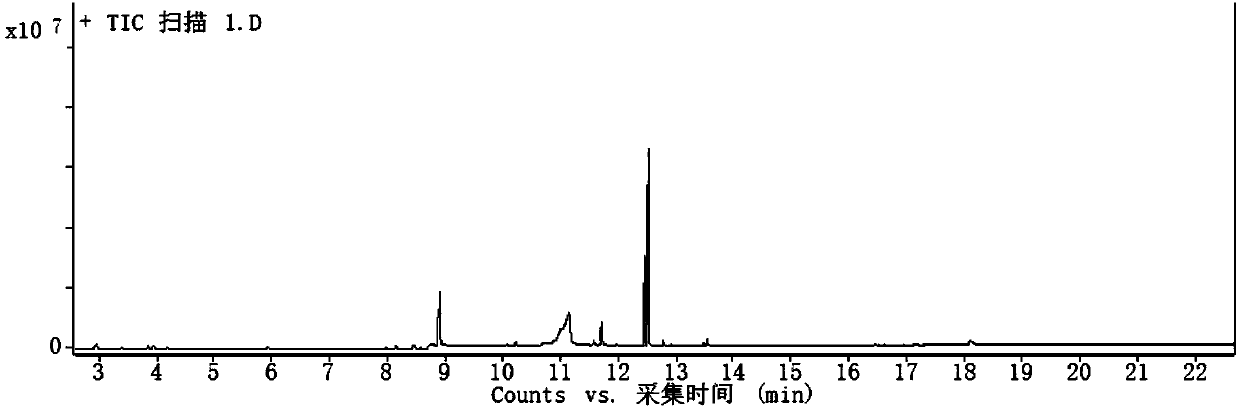

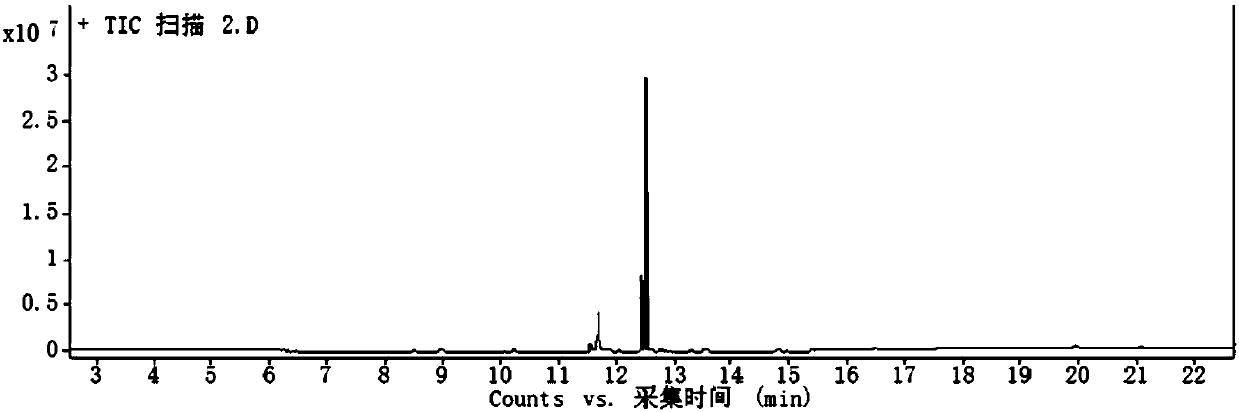

[0047] Effect determination: The extract and raffinate obtained in S2 were analyzed by GC-MS respectively, the specific results are as follows image 3 and ...

Embodiment 2

[0050] The present embodiment provides a kind of method that reclaims organic solvent from maleic anhydride wastewater, comprises the steps:

[0051] S1: Mix 100mL maleic anhydride wastewater and 100mL ethyl acetate evenly, place them in a separatory funnel, and let stand for extraction;

[0052] S2: After the layers are clearly separated, the two phases are separated with a separatory funnel to obtain the extract and raffinate;

[0053] S3: Nitrogen bubbling of the extract by rectification to separate the extractant ethyl acetate from the organic solvent, wherein the separated organic solvent includes organic substances that are difficult to biodegrade such as DIBE, DBP and the like;

[0054] S21: The raffinate is bubbled with nitrogen, and the extractant is removed from the raffinate to obtain residual waste water.

[0055] Effect measurement: The residual wastewater obtained in S21 and the raw material maleic anhydride wastewater in S1 were tested for COD respectively. It ...

Embodiment 3

[0057] The present embodiment provides a kind of method that reclaims organic solvent from maleic anhydride wastewater, comprises the steps:

[0058] S1: Mix 100mL maleic anhydride wastewater and 100mL chloroform evenly, place in a separatory funnel, and let stand for extraction;

[0059] S2: After the layers are clearly separated, the two phases are separated with a separatory funnel to obtain the extract and raffinate;

[0060] S3: Nitrogen bubbling of the extract by rectification to separate the extractant chloroform from the organic solvent, wherein the separated organic solvent includes organic substances that are difficult to biodegrade such as DIBE and DBP;

[0061] S21: The raffinate is bubbled with nitrogen, and the extractant is removed from the raffinate to obtain residual waste water.

[0062] Effect measurement: The residual wastewater obtained in S21 and the raw material maleic anhydride wastewater in S1 were tested for COD respectively. It was found that the CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com