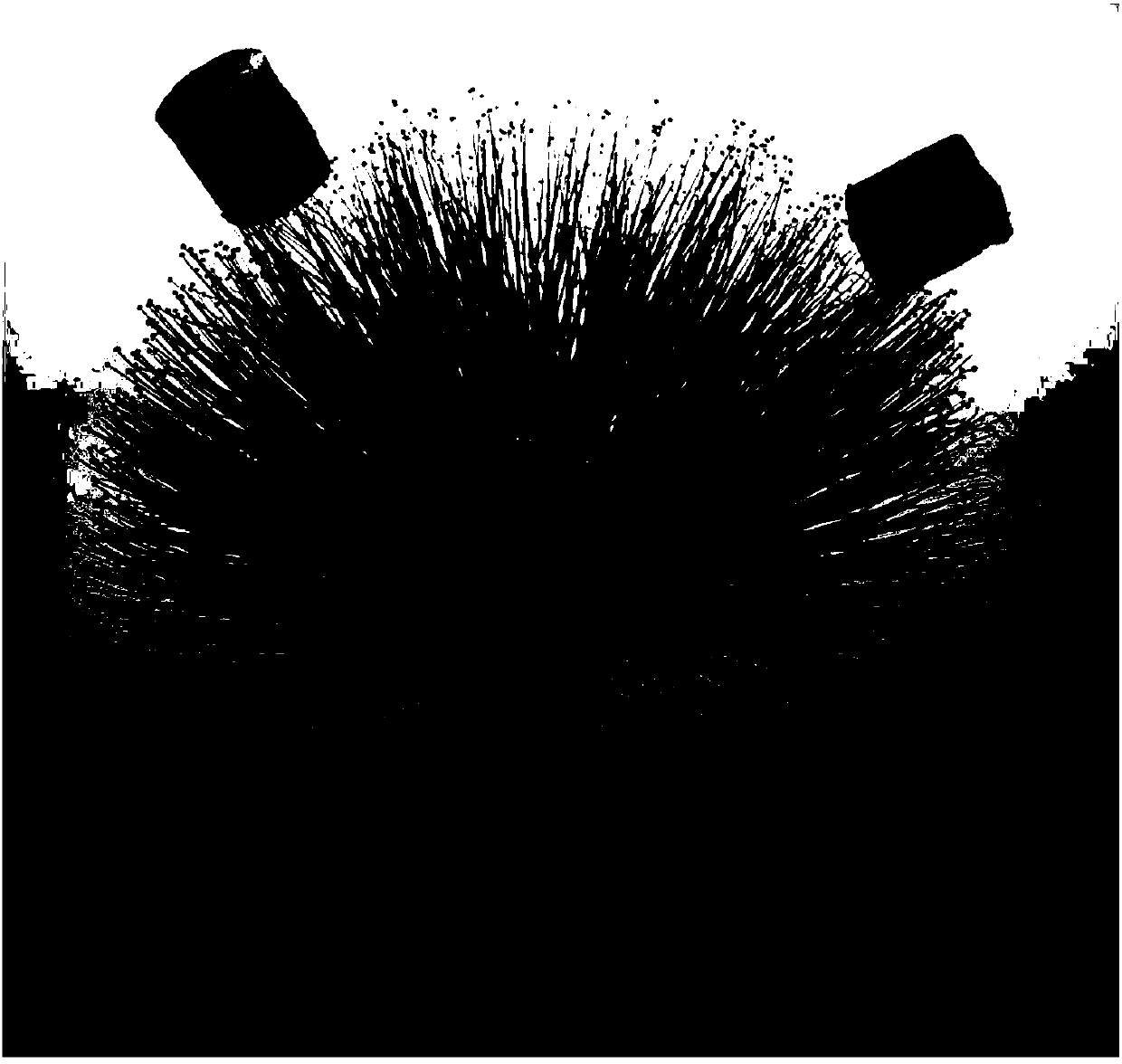

Ultralight ultra-amphiphilic type three-dimensional graphene foam material, and preparation method and application thereof

A graphene foam, super-amphiphilic technology, applied in graphene, chemical instruments and methods, other chemical processes, etc., can solve the problems of poor mechanical strength, single infiltration function, etc., and achieve ultra-light infiltration performance, specific surface area expansion, The effect of enhancing the degree of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

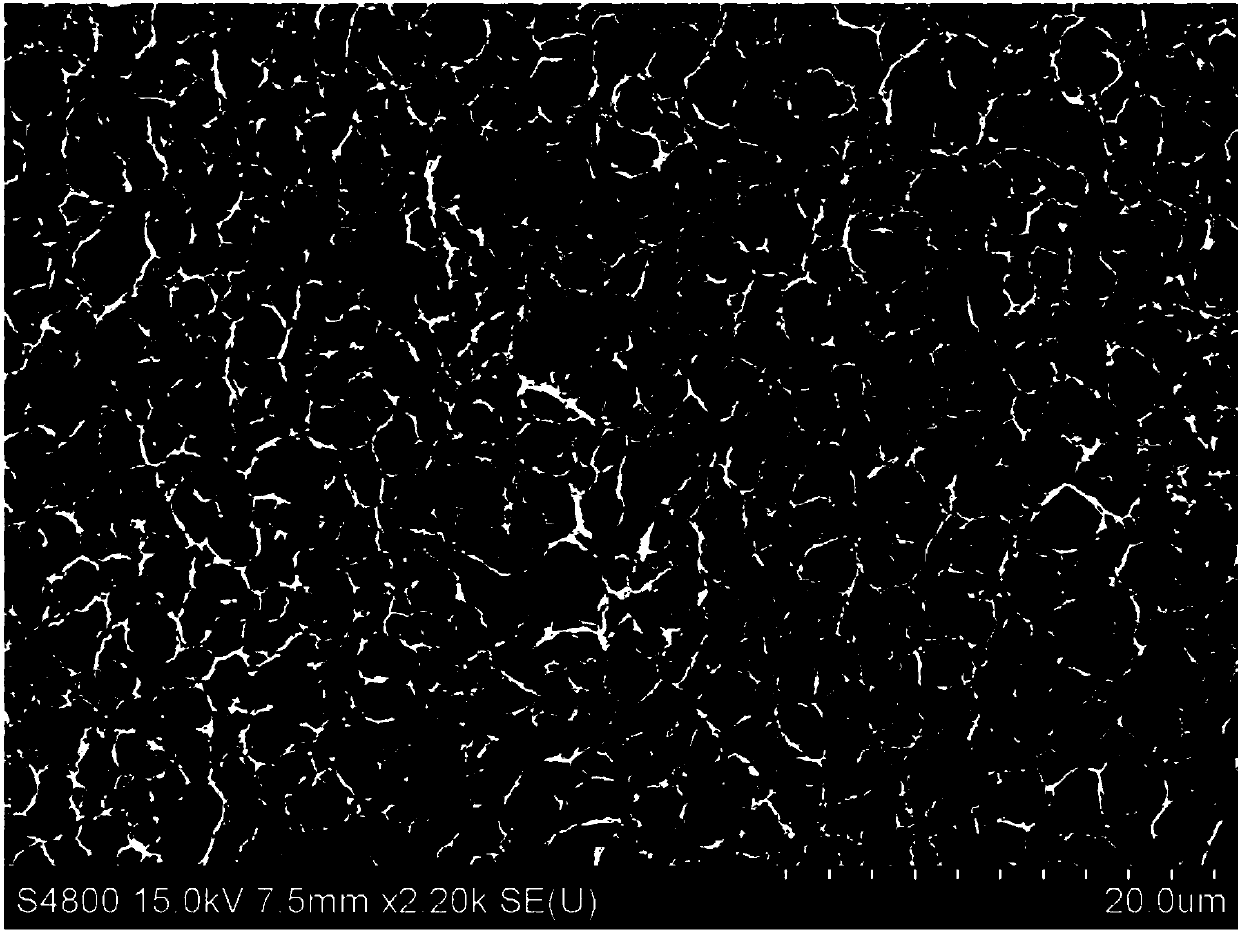

[0029] To prepare a graphene oxide solution, weigh 1 g of graphene oxide solid and add ultrapure water to prepare 500 ml of graphene oxide aqueous solution with a mass concentration of 2 mg / ml, and disperse it by ultrasonic for 1 hour at room temperature.

[0030] Weigh the phosphoethanolamine powder according to the values in Table 1, put it into 15mL, 2mg / ml graphene oxide aqueous solution and ultrasonically disperse it for 1h, then add the mixed solution into a 25mL hydrothermal reaction kettle, and put the hydrothermal reaction kettle into Put it into a stainless steel jacket and screw it tightly, place it in an oven, raise the temperature to 180°C and keep it for 12 hours. Three samples were prepared for each example.

[0031] The above reaction product was naturally cooled to room temperature, washed with ethanol and water, and freeze-dried for 24 hours. In Examples 1 to 5, the samples of each example were respectively annealed at 800°C, 900°C, and 1000°C for 1 hour u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com