A continuous processing equipment that uses electromagnetic suction to realize automatic cutting and waste collection

A technology of automatic blanking and electromagnetic suction, which is applied in metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problem that waste chips cannot be processed, reclaimed materials and workpieces, waste chips cannot be recycled, and unstable Recycling effect and other issues, to achieve the effect of preventing accumulation, high work efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

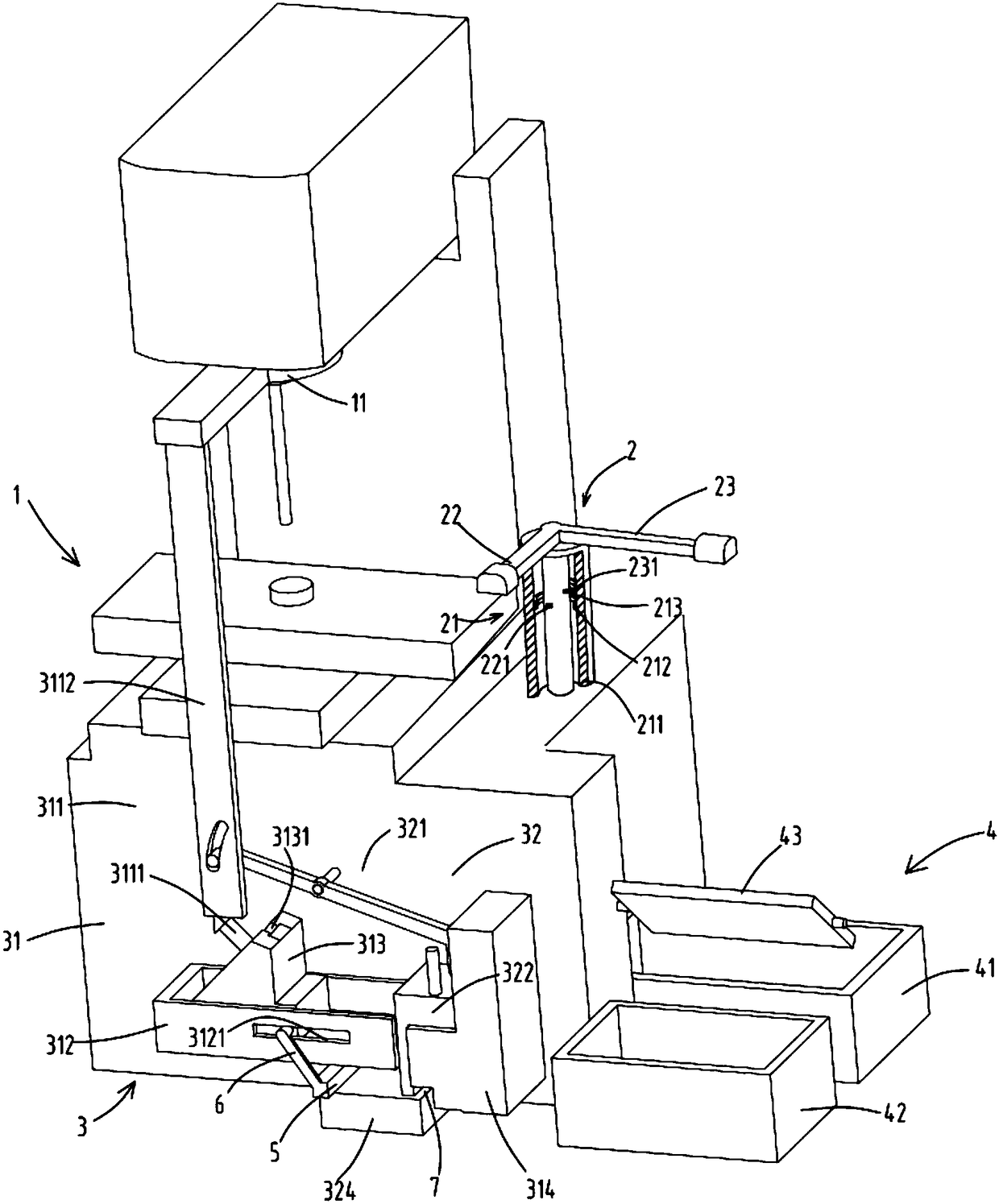

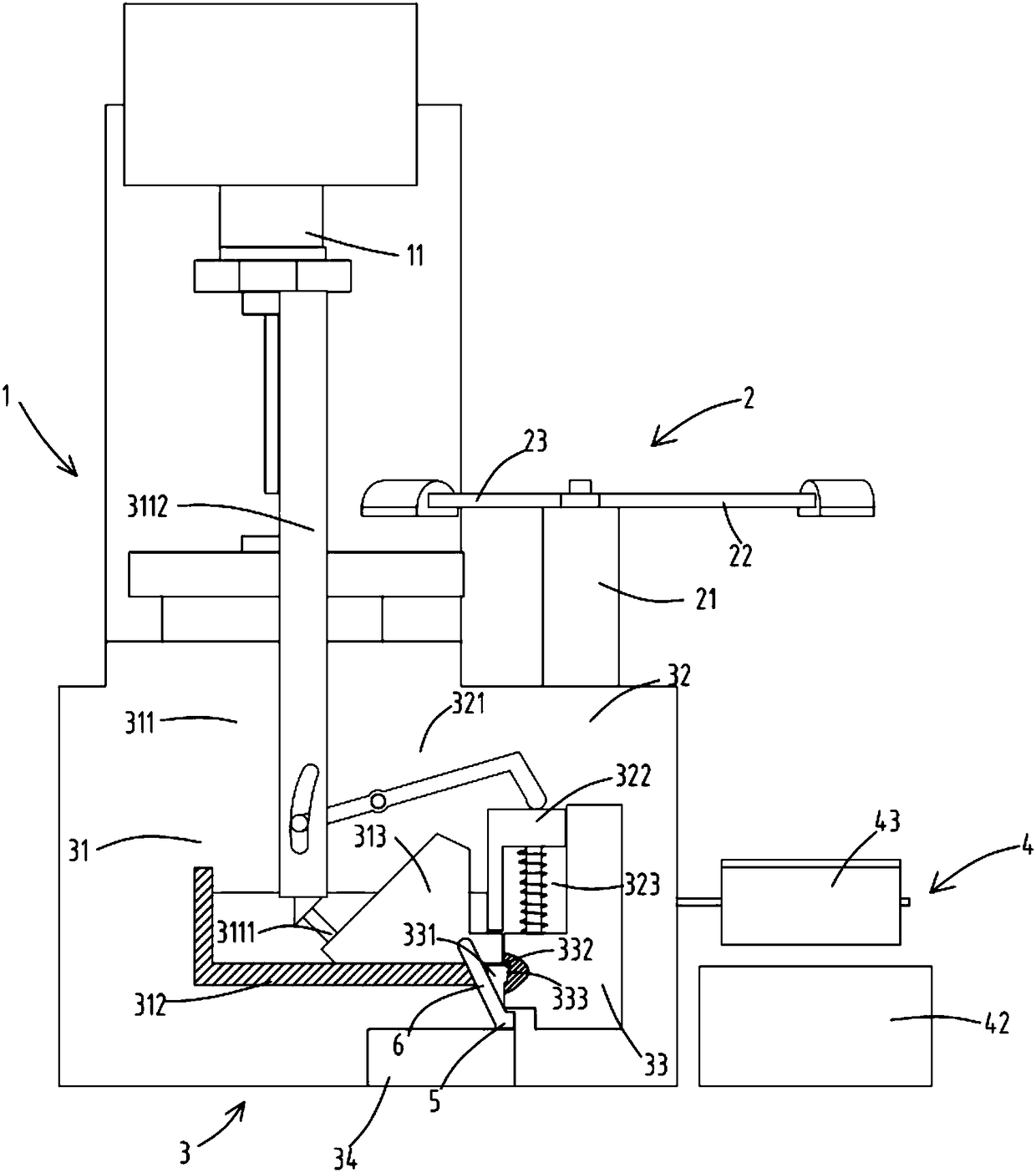

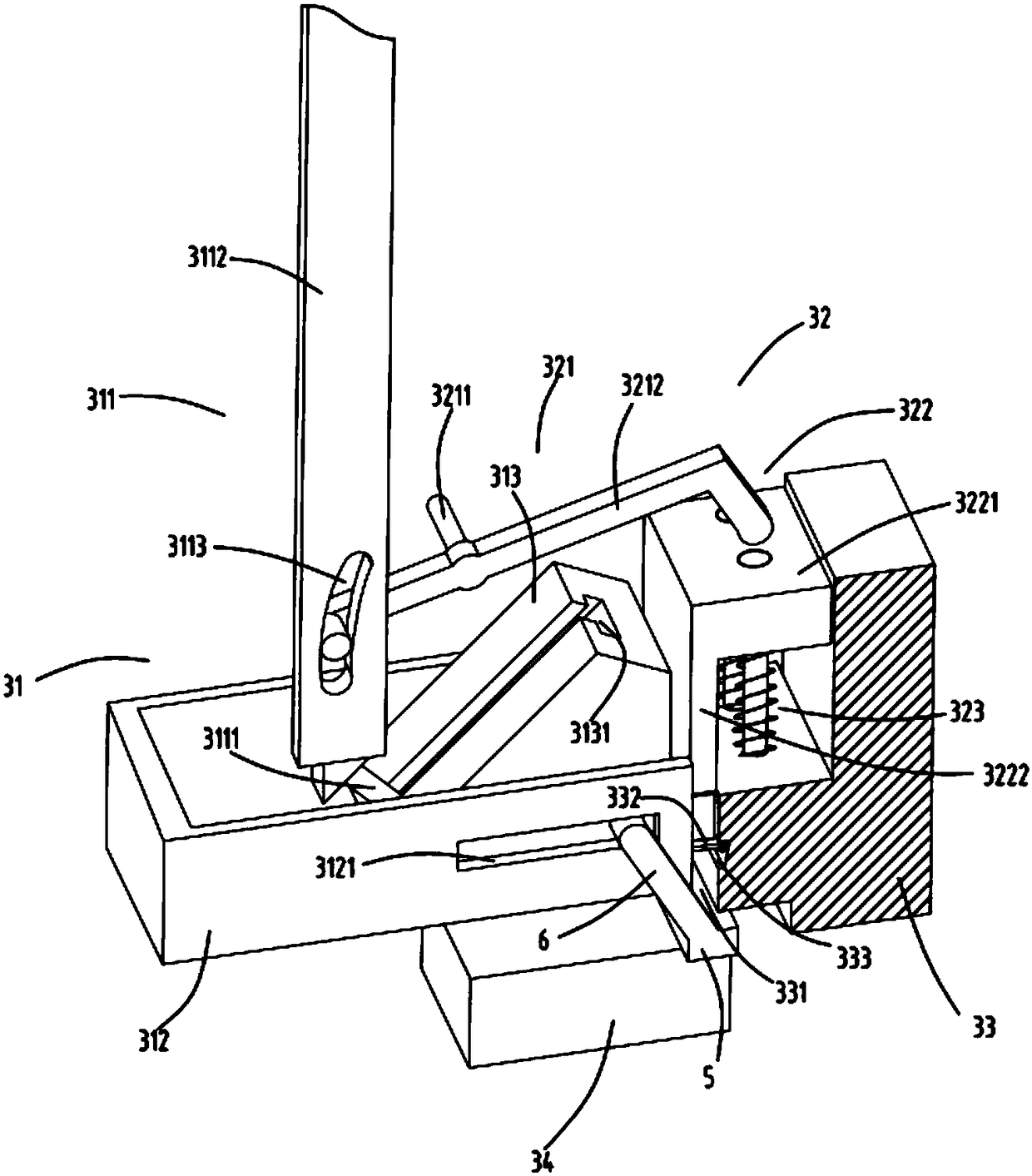

[0035] figure 1 It is a schematic diagram of a continuous processing equipment that uses electromagnetic suction to realize automatic feeding and waste collection. figure 2 It is a schematic front view of a continuous processing equipment that uses electromagnetic suction to realize automatic feeding and waste collection. image 3 It is a partial structural schematic diagram of a continuous processing equipment that uses electromagnetic suction to realize automatic cutting and waste collection. Figure 4 It is a schematic diagram of the structure of the inclined block and the transmission rod, Figure 5 A cross-sectional schematic diagram of the position of the control part, Figure 6 It is a cross-sectional schematic diagram of the position of the control part. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, what is provided in this embodiment is a continuous processing equipment that uses electromagnetic suction to realize au...

Embodiment 2

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the machine tool 1, the waste collection device 3 and the material collection part 4 form an included angle of 120 degrees with the power shaft 24 as the center;

[0048] The setting of this kind of angle can ensure that the two steps of material suction by the material adsorption mechanism 22 and waste removal by the waste adsorption mechanism 23 are carried out at the same time, and the two steps of waste suction by the waste adsorption mechanism 23 and dropping by the material adsorption mechanism 22 Simultaneously, so that the number of tim...

Embodiment 3

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that the material collecting part 4 includes a material box a41, a material box b42, and a receiving plate 43 arranged above the material box a41 and the material box b42; the receiving plate 43 are rotatably arranged on the lathe 1; can control material to fall in which feed box by rotating receiving plate 43, can rotate receiving plate 43 and make material fall in the standby feeding box when one of the feed boxes is full and it is too late to transfer.

[0051] Working process: After the machine tool 1 processes a material, the control mechanism 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com