An external mixing atomizing sprayer based on special-shaped hole airflow assisting the shape

A sprayer and special-shaped hole technology, applied in spraying devices, spraying devices, etc., can solve the problems of poor droplet distribution uniformity, low atomization quality, waste of pesticide resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, innovative points, and achieved effects of the present invention easy to understand, the present invention will be further elaborated below.

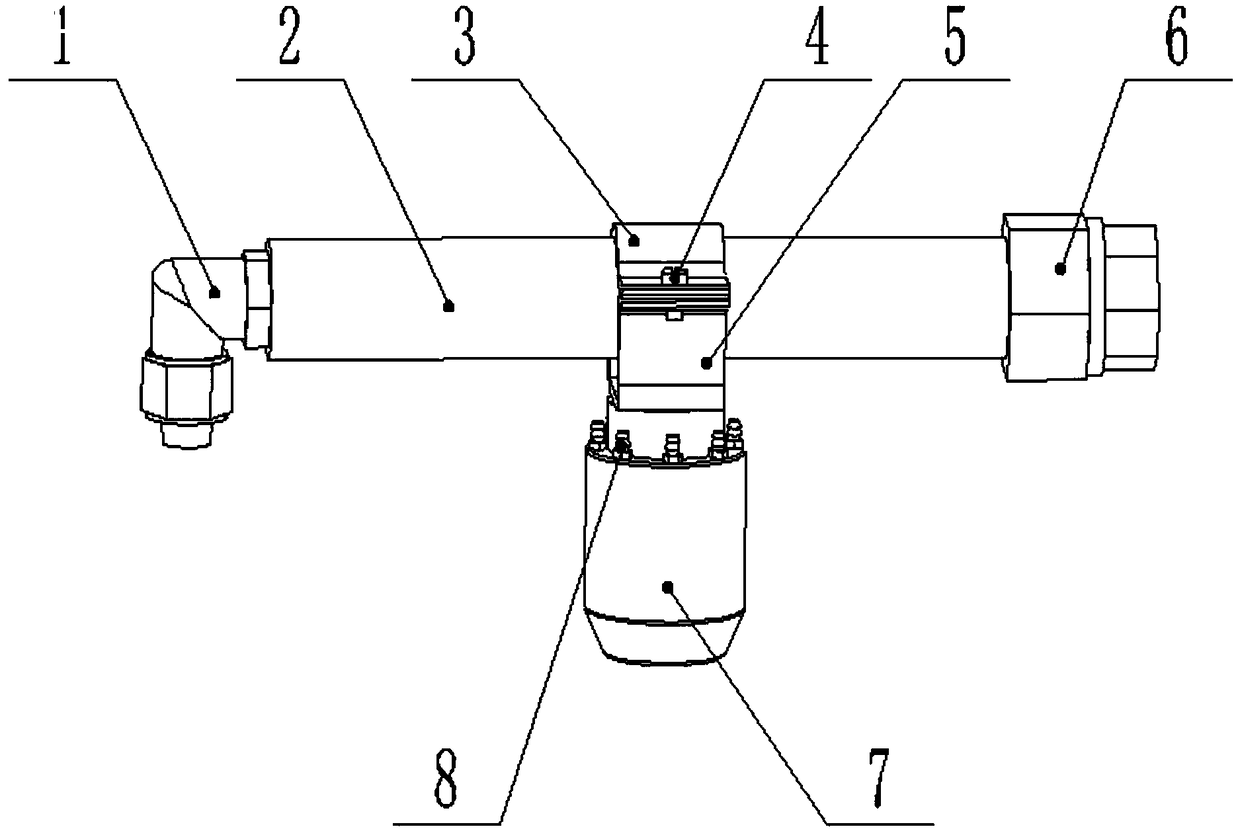

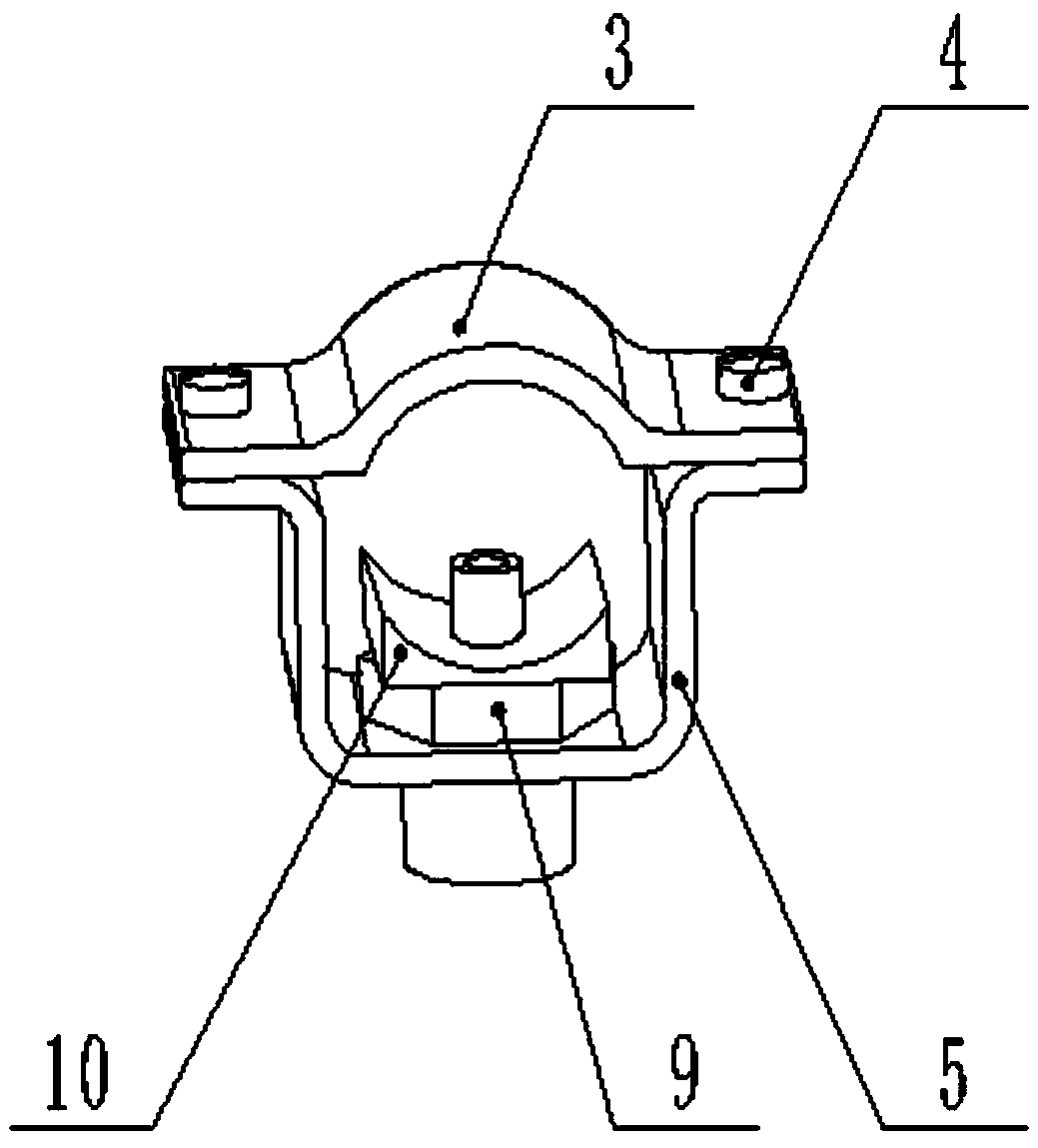

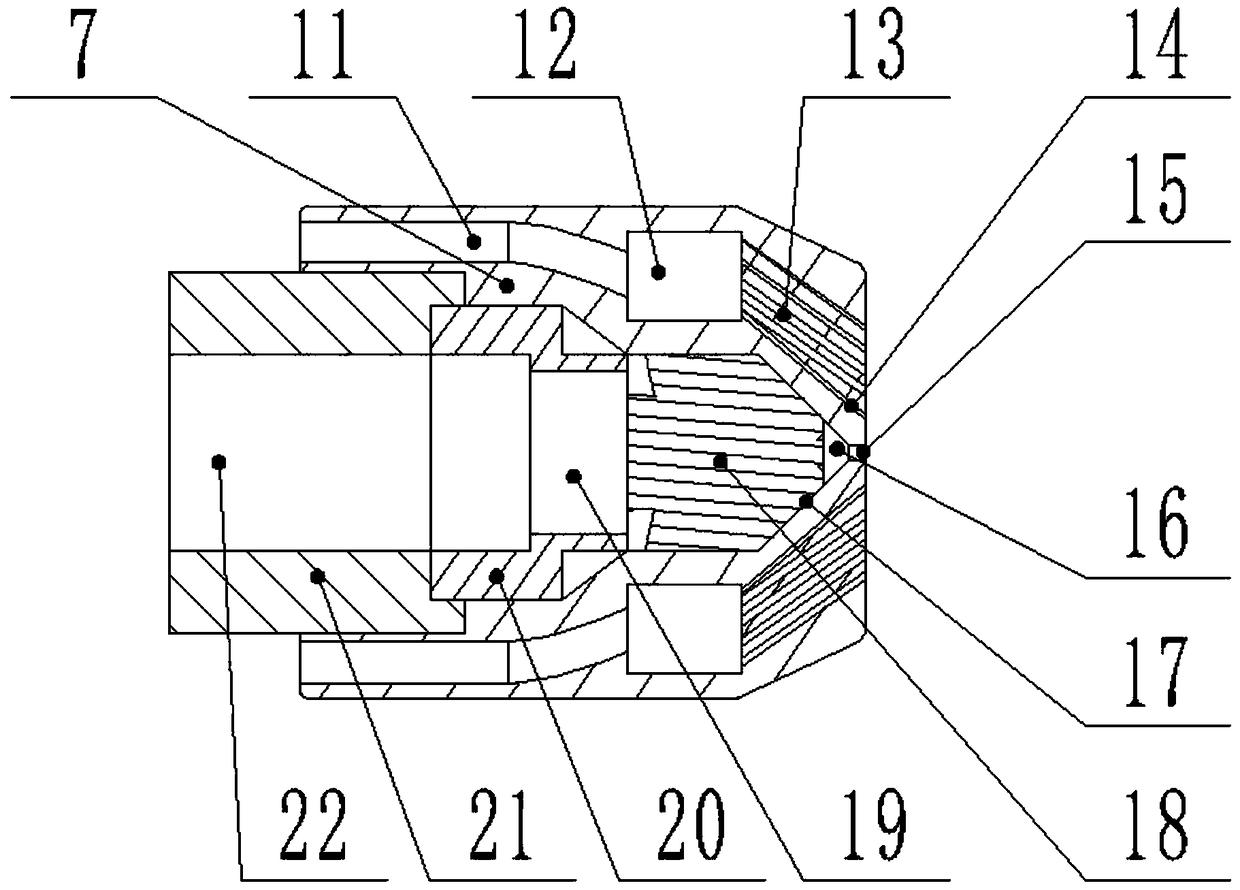

[0029]The present invention is to provide an externally mixed atomizing sprayer based on special-shaped hole airflow assisting shape. What needs to be explained for the patent name of the present invention is: firstly, the special-shaped hole refers to the hole whose shape is non-circular, and secondly, the shape refers to the shape of the folded shape. A droplet group that approximates a solid cone fog distribution can be achieved. The sprayer is formed by assembling a plurality of detachable parts designed in separate parts, which includes a water pipe (2) and its connecting seal, a spliced hole connecting assembly, a pneumatic joint (8) and a nozzle. The present invention can be mainly divided into three parts for introduction: the first is the water pipe (2) and its connecting seal, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com