Micro-pulverizer having graded dust recycling function

A micro pulverizer and recovery pipeline technology, applied in feed, grain processing, food science, etc., can solve the problems of limited pulverizer adaptability, fixed and unadjustable output particle size, poor dust removal effect, etc., to achieve small resistance and flexible use , High dust removal efficiency and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

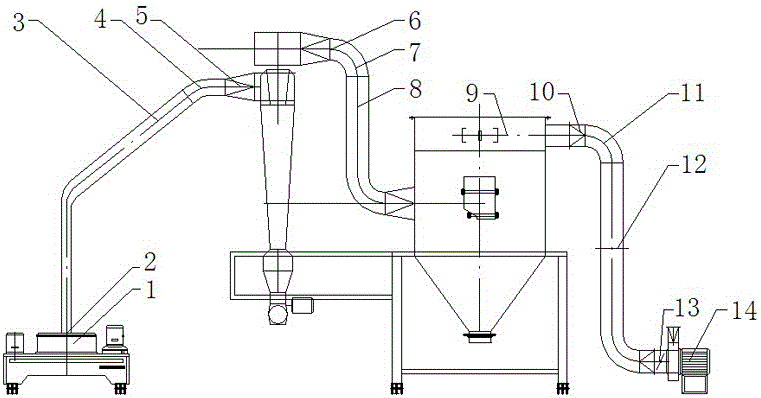

[0014] Embodiment 1: A kind of pulverizer of graded recovery dedusting, its structure diagram is as follows figure 1 As shown, it includes a crushing host 1, a cyclone separator 5, a bag filter 9 and a blower fan 14.

[0015] The crushing main engine 1 is communicated with the cyclone separator 5 through a recovery pipeline, the recovery pipeline includes a straight pipe 3, and the angle of the straight pipe 3 is 120°, and the recovery pipeline is separated from the cyclone The joint of the device 5 is provided with a recovery sealing device 4, and the recovery sealing device 4 is a square-diameter-circular sealing device. The inclination angle of the curved straight pipe ensures the smooth passage of the powder-laden gas and avoids falling back, while the square-diameter-circle sealing device prevents dust from leaking out and protects the working environment. This function will not be described in detail.

[0016] The cyclone separator 5 communicates with the bag filter 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com