Air separation process and device for improving air separation efficiency and reducing damage ratio of materials

A technology of air separation and material, applied in the fields of food science, tobacco, tobacco processing, etc., can solve the problems of high noise, dust pollution and high labor intensity in the threshing workshop, so as to reduce the crushing rate, reduce the wind resistance, and improve the wind separation. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

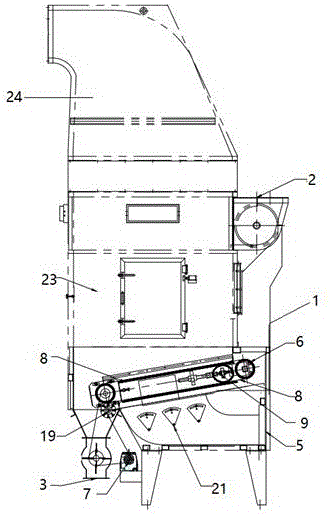

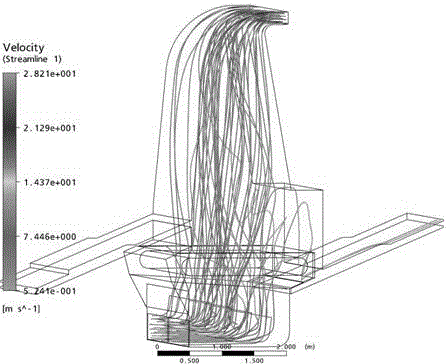

[0044] Embodiment 1: as figure 1 , figure 2As shown, an air separation process that improves the air separation efficiency and reduces the material crushing rate, the air flow wind passes through the wind mesh belt 8 from below and then enters the air separation warehouse 23, the wind mesh belt 8 is a braided mesh belt, The size of the wind mesh is 1.3mm*1.6mm; the mesh belt-type wind-passing mesh belt 8 is used instead of the traditional steel punching mesh plate, thereby canceling the chain-type transmission mode, and the belt-type transmission replaces the chain transmission, which reduces wind resistance and improves wind resistance. field uniformity, improve the accuracy of air distribution, reduce noise, reduce material clamping and return, and adopt roller 6-type transmission, which has the effect of energy saving and low noise, and achieves the purpose of energy saving and environmental protection; the material passes through the air lock from the feed port 2 The fee...

Embodiment 2

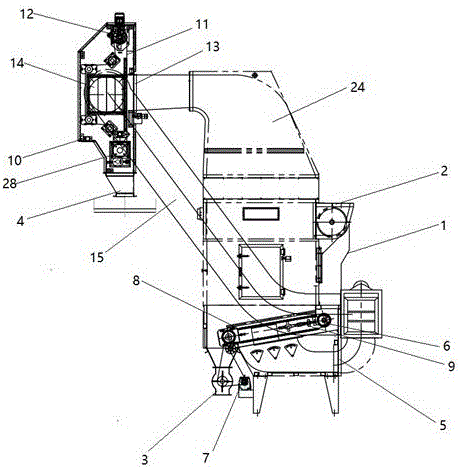

[0046] Embodiment 2: as figure 2 , Figure 4 , Image 6 As shown, an air separation device for improving the efficiency of air separation and reducing the crushing rate of materials comprises an air separation body 1, a feed port 2, and a heavy material discharge port 3 placed at the bottom of the air separation body 1, which is located at the air separation body 1. The light material discharge port 4 above the sub-body 1, the filter screen device is located below the feed port 2 and placed in the lower part of the air sub-body 1, and the air inlet 5 is located at the bottom of the air sub-body 1 and is located under the filter screen device. The filter screen device includes a drum 6 placed at both ends, a transmission motor 7 for providing power, a wind mesh belt 8 for passing the wind filter material, the wind mesh belt 8 is set on the roller 6, and the wind mesh belt 8 is placed below Deviation correction device 9; the light material outlet 4 is connected to the flexibl...

Embodiment 3

[0051] Embodiment 3: as Figure 7 As shown, the device is that at least two groups of devices are connected and combined through a combination system. Pipe 36, qualified material discharge vibrating screen 37;

[0052] Wherein: the flotation blower 32 is installed on the outer bottom of the air separation body 1 and connected to the air inlet 5, and the negative pressure suction pipe 15 is divided into a flotation negative pressure air pipe 35 and a feeding negative pressure air pipe 36 at both ends of the outer cover 10 , the flotation negative pressure air duct 35 is connected to the flotation fan 32, the feeding negative pressure air duct 36 is connected to the feeding fan 33, the qualified material discharge vibrating screen 37 is arranged under the flexible blanking equipment, and the heavy material discharge port 3 Connected to the feeding positive pressure air pipe 34, the bottom of the feeding fan 33 is connected to the flexible blanking device placed on the feed port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com