Water carrier suite and spray irrigation system

A technology of water extractor and kit, which is applied in the field of pasture planting water fetch kit and sprinkler irrigation system, which can solve the problems of inconvenient connection, hindering the development and utilization of triangular land, high cost, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

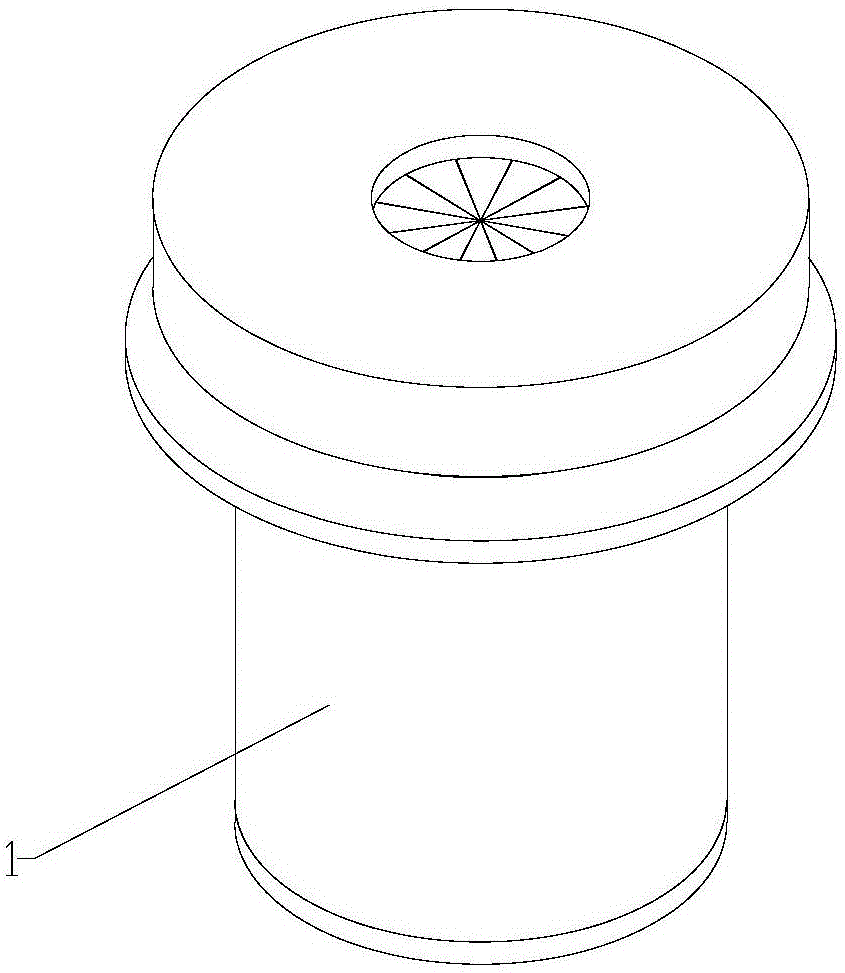

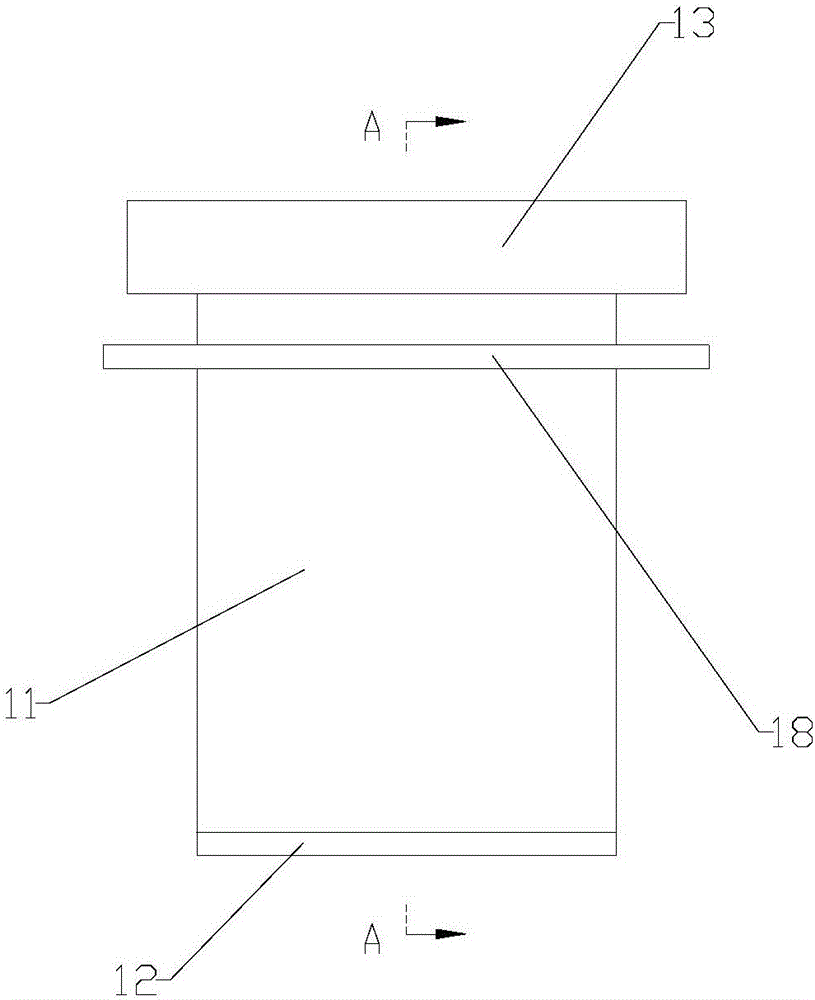

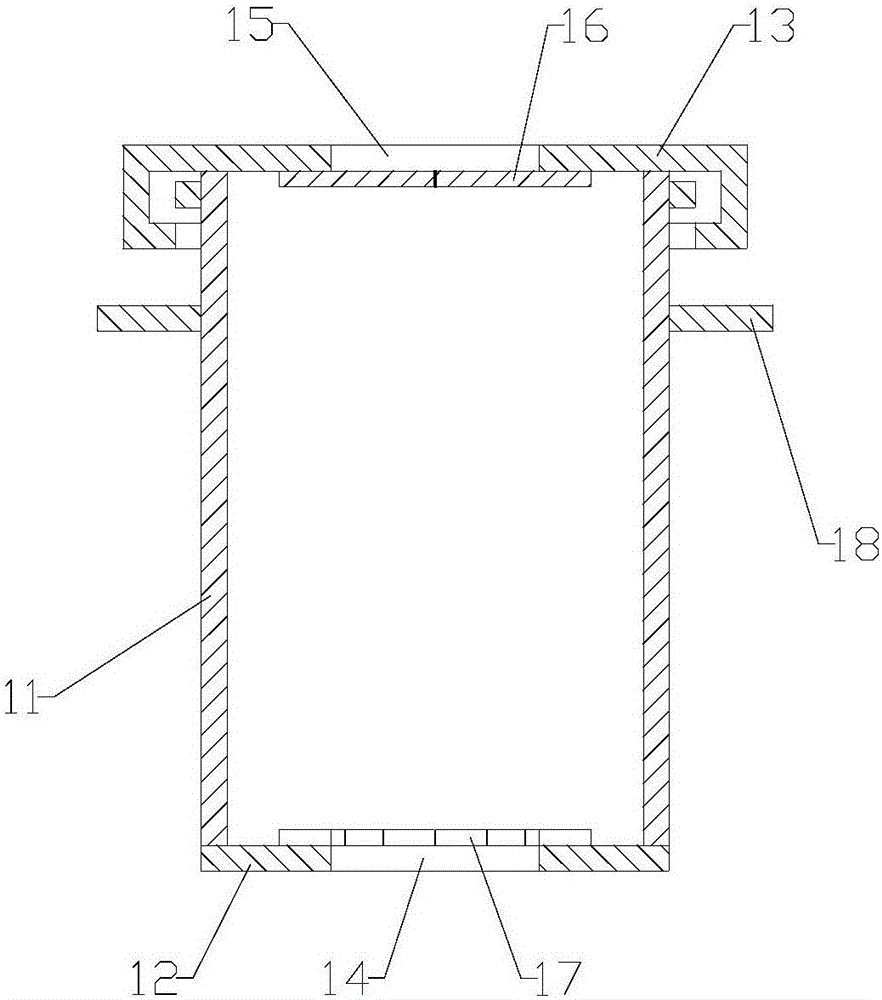

[0036] proper reference Figure 1-Figure 3 As shown, the water dispenser kit of the basic embodiment provided by the present invention may include a pipe body 11 with open upper and lower ends and an upper end cover 13 installed at the upper end opening of the pipe body 11, and the upper end cover 13 closes the upper end cover 13. The upper end of the pipe body 11 is open, and the upper end cover 13 is provided with a second through hole 15 . The through hole 15 is a closing device for closing the second through hole 15 when the vertical rod 6 pulls out the pipe body 11 .

[0037] In the above-mentioned basic embodiment, the pipe body 11 with open upper and lower ends can adopt various shapes of tubular structures, for example, a round pipe, a square pipe, a pipe with a polygonal cross-section, or a pipe with inconsistent upper and lower pipe diameters etc., in the present invention, the pipe body 11 is preferably made of a round pipe with upper and lower openings. Consideri...

no. 2 example

[0048] The difference between this embodiment and the first embodiment is that the closing device installed on the upper end cover 13 is different from the first embodiment.

[0049] In this embodiment, the closing device may include a rotating shaft fixedly installed on the lower end surface of the upper end cover, a baffle plate rotatably installed on the rotating shaft and capable of closing the second through hole, and a baffle fitted on the rotating shaft. One free end of the torsion spring is fixed on the upper end cover, and the other free end is fixedly connected with the baffle. When the pole is not inserted, the torsion spring provides elastic force so that the baffle is pressed against the upper end cover. The second through hole is closed on the lower end surface. When the vertical rod is inserted, the lower end of the vertical rod pushes the baffle to overcome the elastic force of the torsion spring and rotates downward to open the second through hole. The second ...

no. 3 example

[0051] The difference between this embodiment and the first embodiment is that, referring to Figure 1-Figure 4 As shown, the water dispenser kit provided in this embodiment also includes a lower end cover 12 installed at the lower end opening of the pipe body 11, the lower end cover 12 closes the opening of the lower end of the pipe body 11, and the lower end The cover 12 defines a first through hole 14 .

[0052] By installing the lower end cap 12 on the pipe body 11 and opening the first through hole 14 on the lower end cap 12 , the branch pipeline and its joints can be inserted into the pipe body 11 through the first through hole 14 . At the same time, the lower end cover 12 is provided at the lower end of the pipe body 11, which can prevent the sinking of the water dispenser set after a period of use to a certain extent.

[0053] The lower end cover 12 can be fixedly installed on the pipe body 11 by various appropriate methods, such as common connection methods such as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com