Ribbon spring for sprag-type one-way clutch, and sprag-type one-way clutch

A technology of one-way clutches and wedges, applied in one-way clutches, clutches, gear transmission mechanisms, etc., can solve problems such as abnormal friction, wedge application, peeling, etc., and achieve reliable functions and smooth sliding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

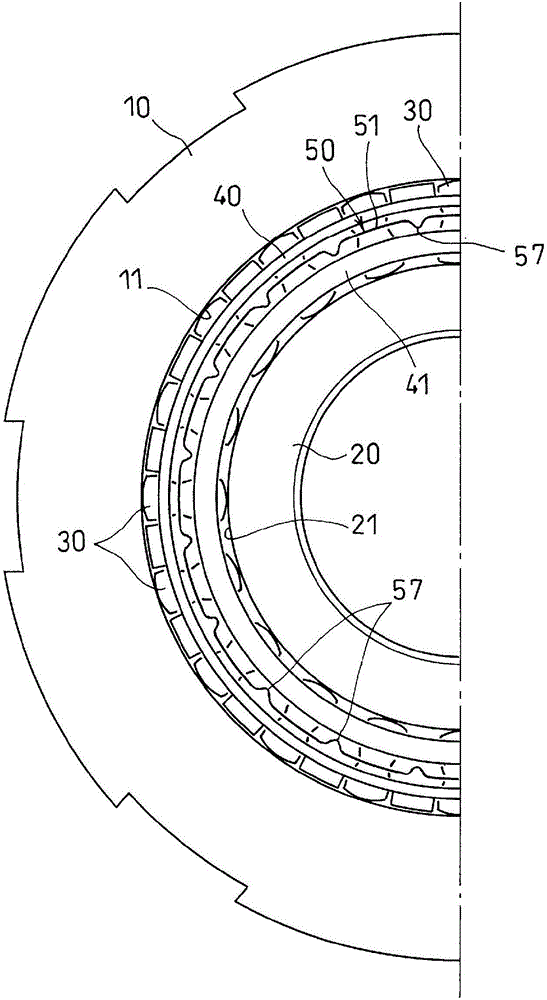

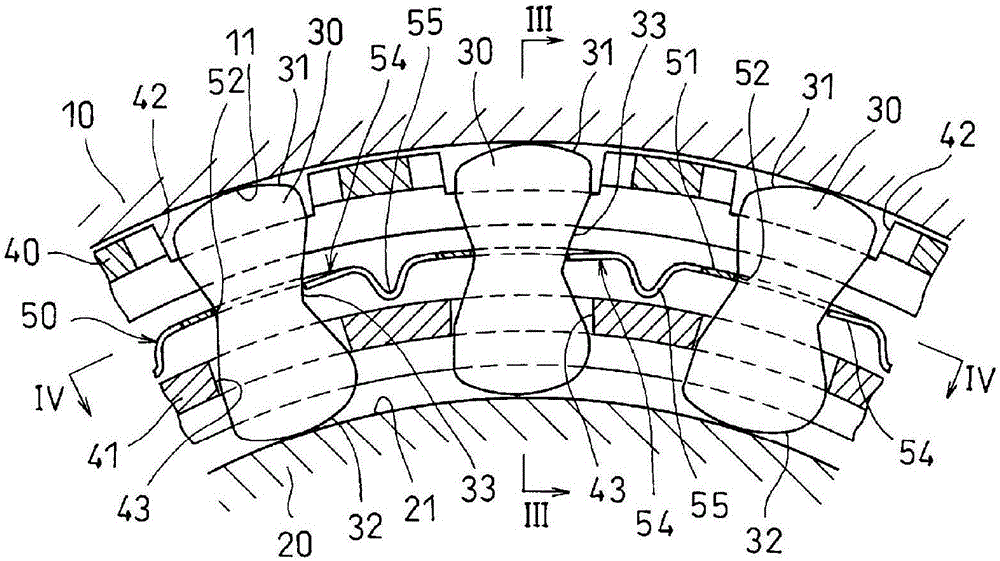

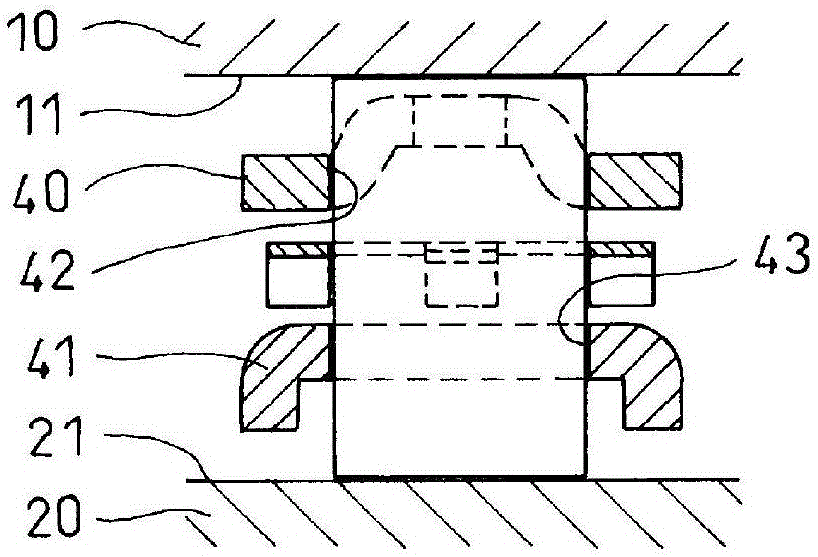

[0026] Hereinafter, embodiments of the present invention will be described based on the drawings. like figure 1 as well as figure 2 As shown, the sprag type one-way clutch has an outer ring 10 and an inner ring 20 assembled inside, and a plurality of sprags 30 are assembled between the outer ring 10 and the inner ring 20 . Further, an outer cage 40 and an inner cage 41 for holding the wedge 30 are assembled between the outer ring 10 and the inner ring 20 , and a belt spring 50 is assembled between the outer cage 40 and the inner cage 41 .

[0027] The inner diameter surface 11 of the outer ring 10 and the outer diameter surface 21 of the inner ring 20 are formed as cylindrical surfaces. The wedge 30 is cocoon-shaped, and one end is provided with an outer ring side cam surface 31 which engages and separates from the inner diameter surface 11 of the outer ring, and the other end is provided with an inner ring side which engages and separates from the outer diameter surface 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com