System for improving LNG yield of methane cryogenic separation

A cryogenic separation and methane technology, which is applied in the system field of improving the LNG yield of methane cryogenic separation, can solve the problems of increased synthesis compressor power, increased discharge of purge gas, and decreased LNG production, so as to reduce exhaust emissions , increase production, reduce the effect of formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The Examples described below illustrate the present invention in detail, but the present invention is not limited to the following Examples. The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

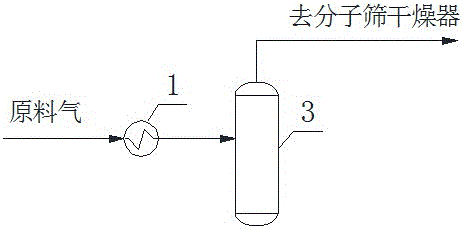

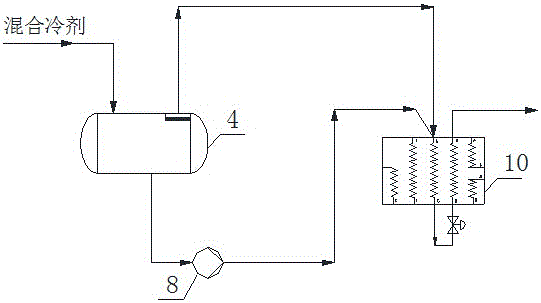

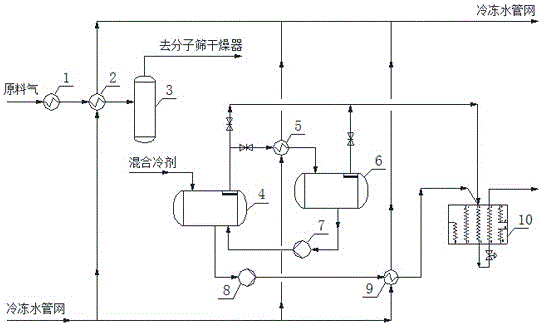

[0027] Such as image 3 A system for improving the yield of methane cryogenic separation of LNG is shown, including a feed gas compression system and a mixed refrigerant circulation system. The feed gas compression system is connected to the compressor outlet cooler 1 inlet through a pipeline, and the compressor outlet is cooled. The outlet of the device 1 is connected to the raw gas inlet chilled water heat exchanger 2, the outlet of the raw gas inlet chilled water heat exchanger 2 is connected to the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com