All-inner plastic composite steel pipe and flange assembly and its forming process

A technology of composite steel pipes and assemblies, which is applied in flange connections, pipes/pipe joints/fittings, pipes, etc., can solve problems such as leakage, and achieve the effects of simple forming process, reasonable structure, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

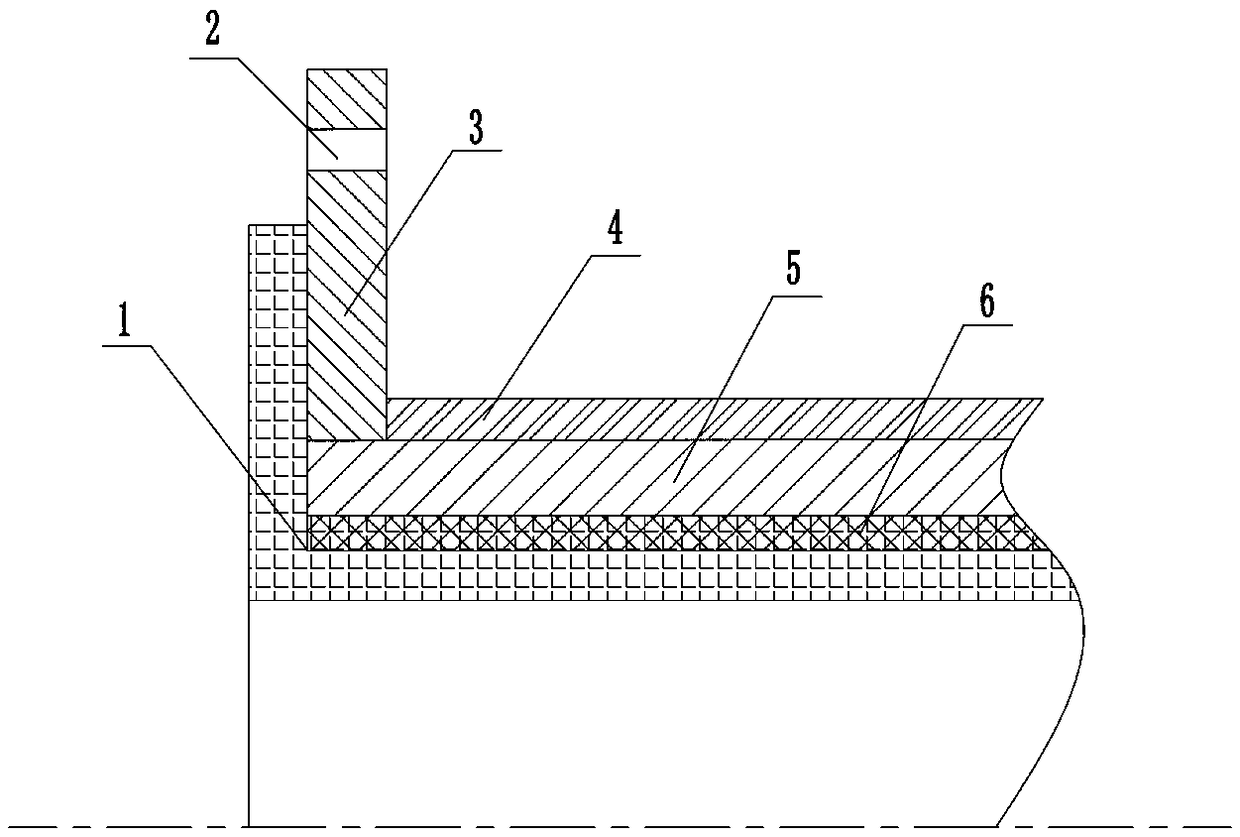

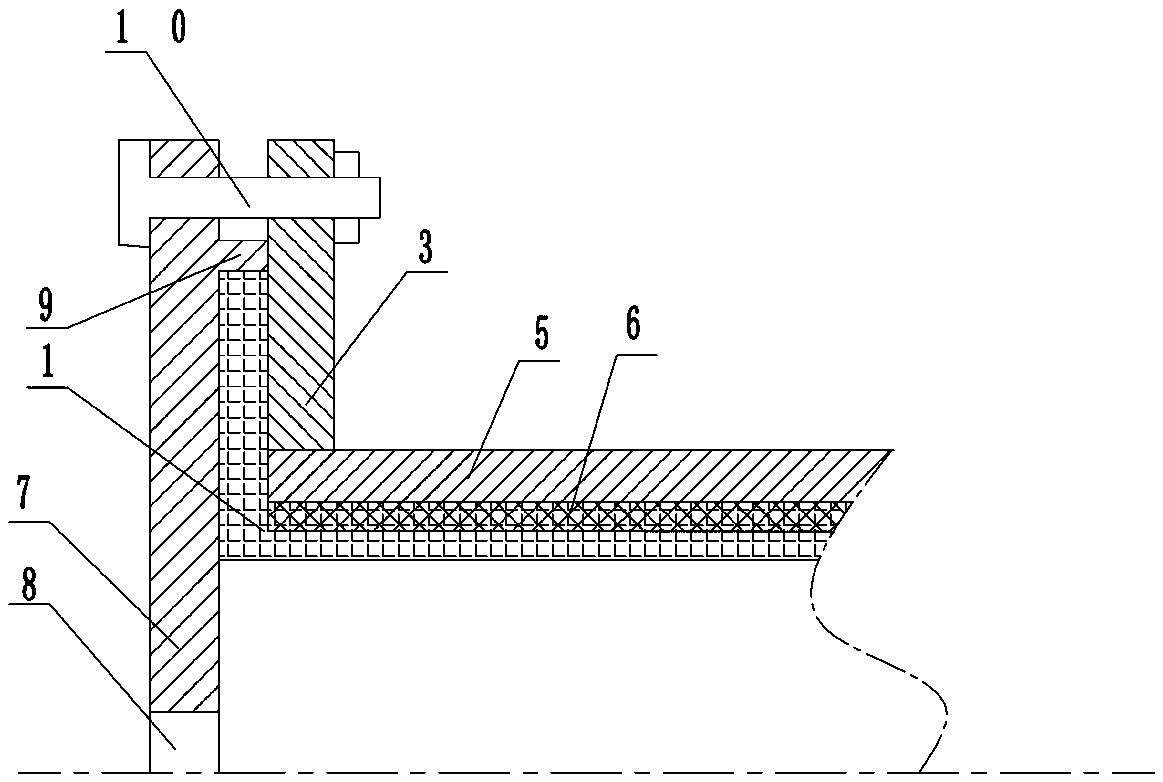

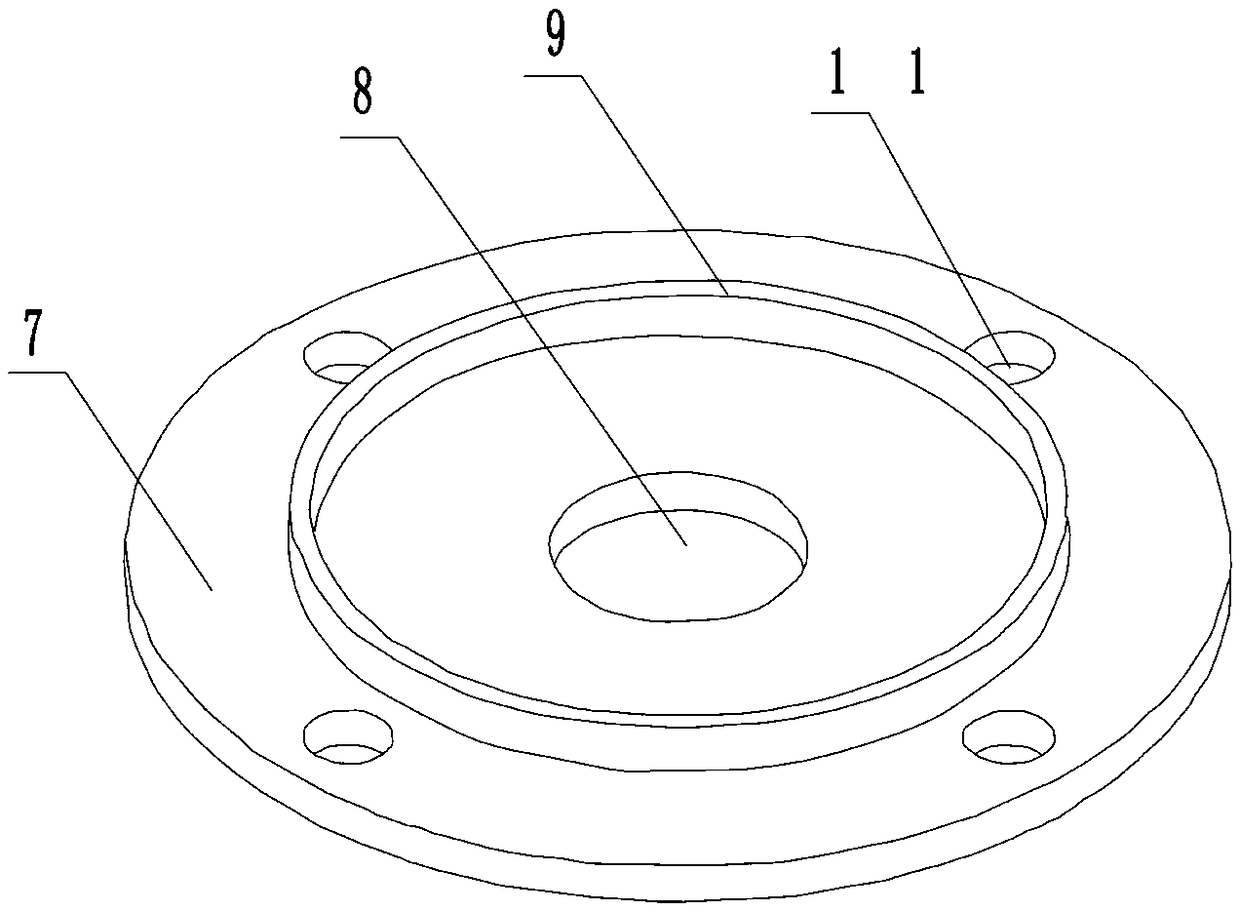

[0029] like figure 1 Shown is an all-inner plastic composite steel pipe and flange assembly. Flange 3 is sleeved on the end of steel pipe 5 and fixed by welding. Flange 3 is provided with a set of flange bolt connection holes 2 for construction connection. Steel pipe 5 The outer wall of the steel pipe 5 is connected with a glass fiber winding layer 4 to prevent the steel pipe 5 from being corroded; The end face of flange 5 and the end face of flange 3 are integrally connected to form a rotational plastic layer 1, which is formed by melting all the built-in plastics and bonding with the relevant mating surfaces of flange 3 and steel pipe 5, and it is connected with the end face of flange 3 and the end face of steel pipe 5 Welding and fixing respectively, the expanded metal mesh 6 is embedded in the rotational plastic layer 1, and the contact surfaces of the rotational plastic layer 1, the steel pipe 5 and the expanded metal mesh 6 are respectively welded and fixed.

[0030] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com