Engine piston capable of saving energy and prolonging service life

A technology for engines and pistons, applied to engine components, machines/engines, pistons, etc., to prevent cylinder scuffing, improve lubrication conditions, and reduce frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

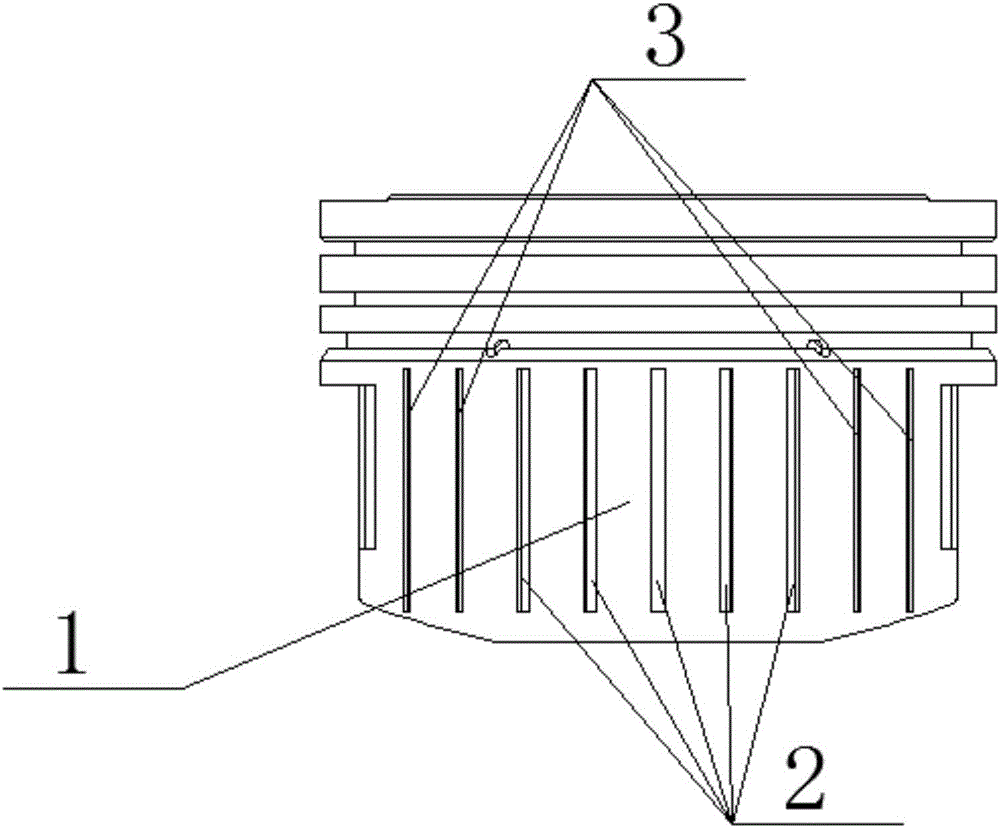

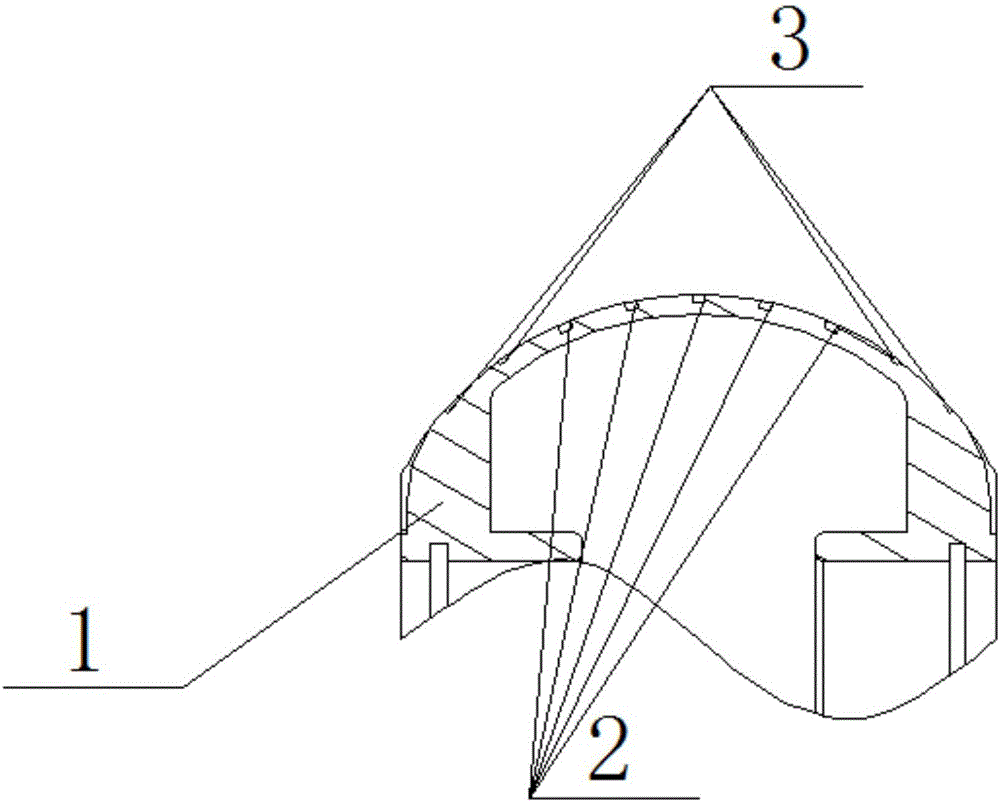

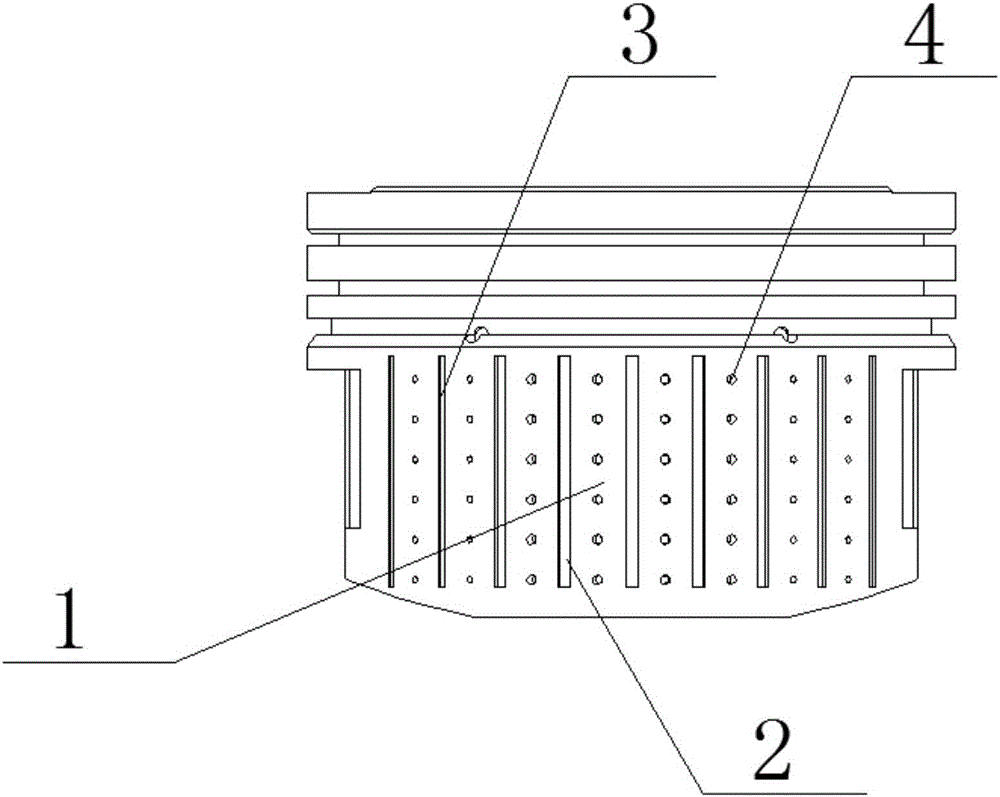

[0033] Such as figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7As shown, in the present invention, vertical concave stripes parallel to each other are evenly arranged at equal intervals on the outer surface of the piston skirt 1, and the vertical concave stripes include the first vertical concave stripes 2 and the second vertical concave stripes. Stripe 3, the first vertical concave stripe 2 with equal depth is designed on the part of piston skirt 1 with less stress, and the second vertical concave stripe 2 is designed on the part of piston skirt 1 with higher stress 3. The second vertical concave stripe 3 is deeper from the top end of the piston and shallower from the bottom end of the piston. The depth changes linearly from the upper part to the lower part of the piston skirt 1, and the linear relationship is Y=-X(H1-H0) / L3, X and Y are the abscissa and ordinate of the point in the plane respectively, H1 is the groove depth of the top end of the piston, H1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com