Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

A filling mining method and stage technology, which is applied in underground mining, filling, surface mining, etc., can solve the problems of poor adaptability to ore body occurrence conditions, difficult ventilation management, and large amount of roadway mining and cutting, so as to avoid blasting large blocks The effect of high efficiency, low labor intensity of workers and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Various embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

[0049] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

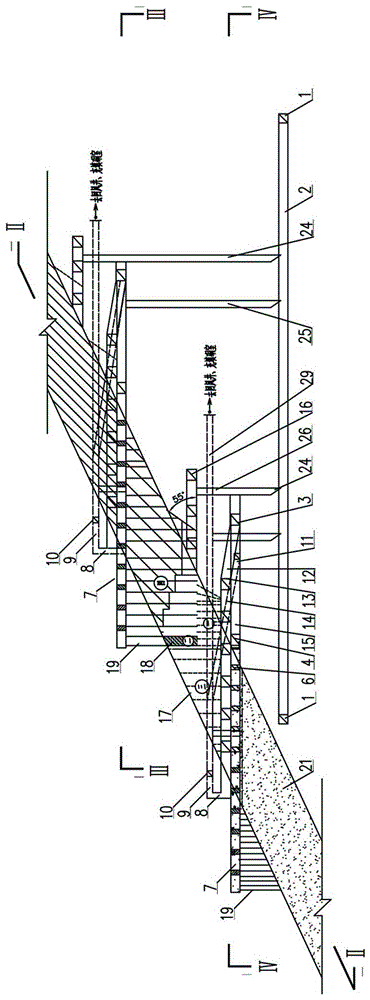

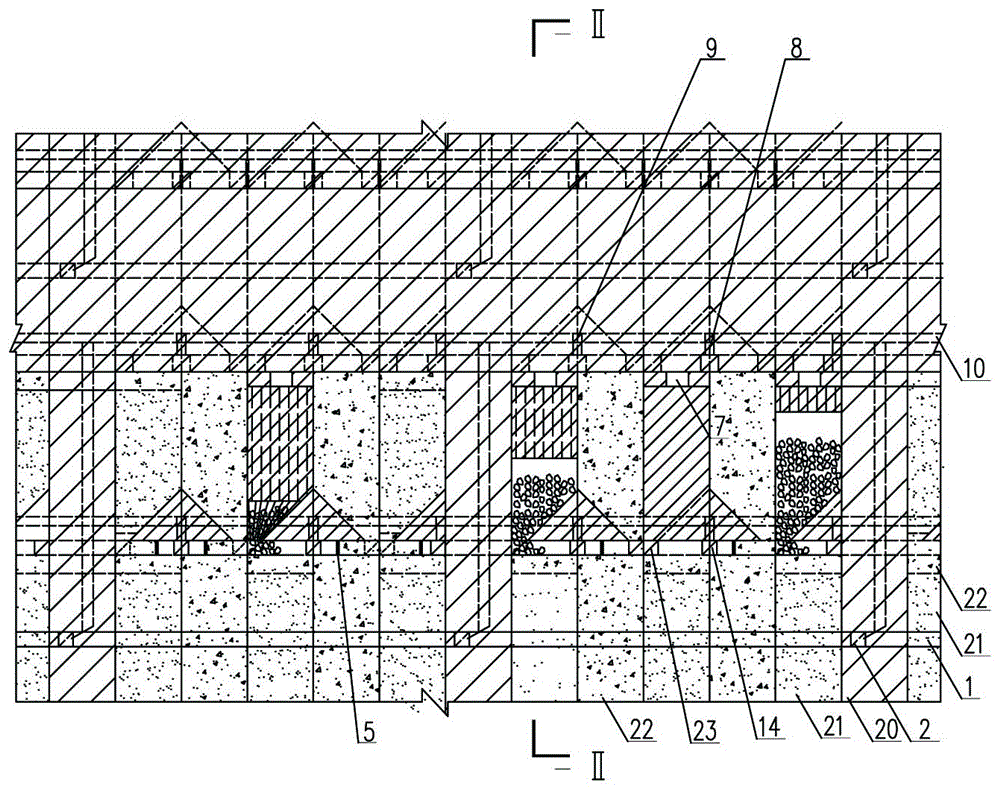

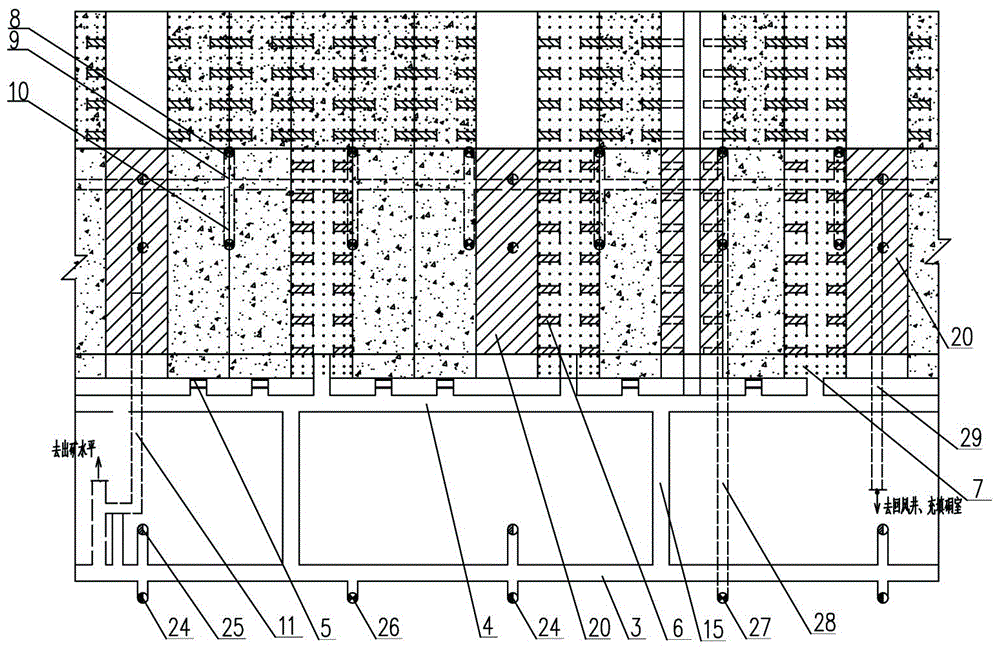

[0050] When mining the ore body, the ore body is first divided into mine rooms arranged at intervals along the direction of the ore body, and one or more mine rooms form a panel. When mining, a panel serves as a mining unit. In the following description, the mining of a mine house will be used to illustrate the up-and-down-stage rock drilling, segmental bottom-cutting and subsequent filling mining method according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com