Method for preparing high-quality graphene through electrochemical reduction

A graphene and electrochemical technology, applied in the electrolysis process, electrolysis components, etc., can solve problems such as environmental pollution, difficult to clean up, complex process, etc., and achieve the effect of reducing production costs, avoiding equipment loss, and easily obtaining raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

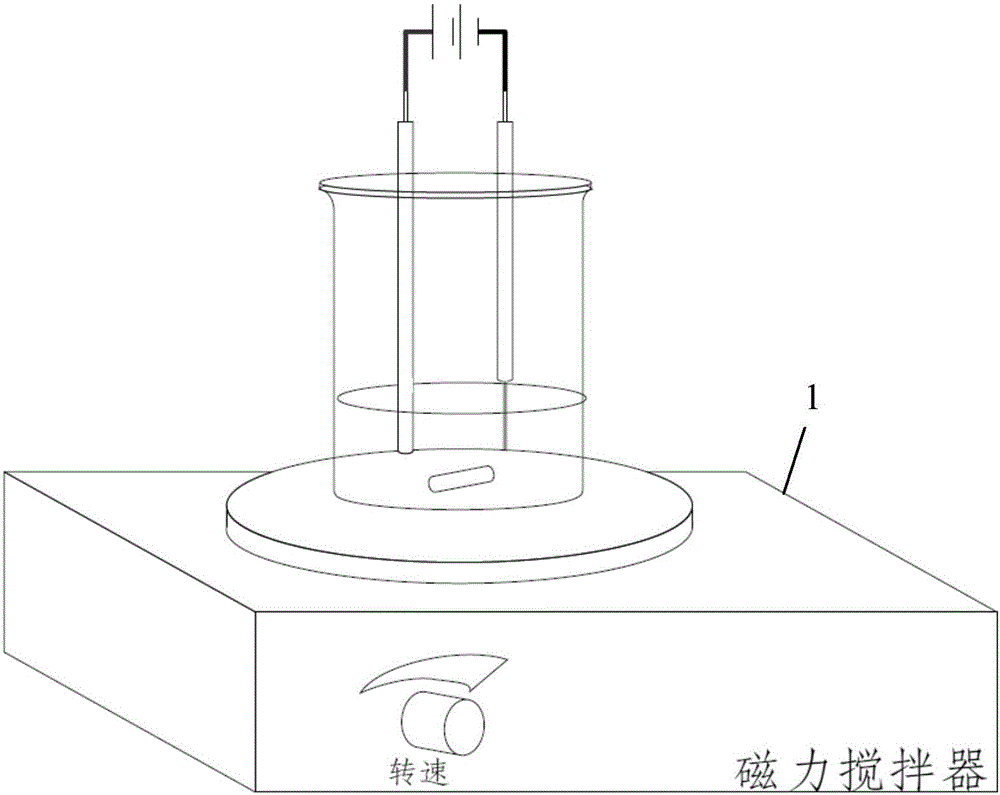

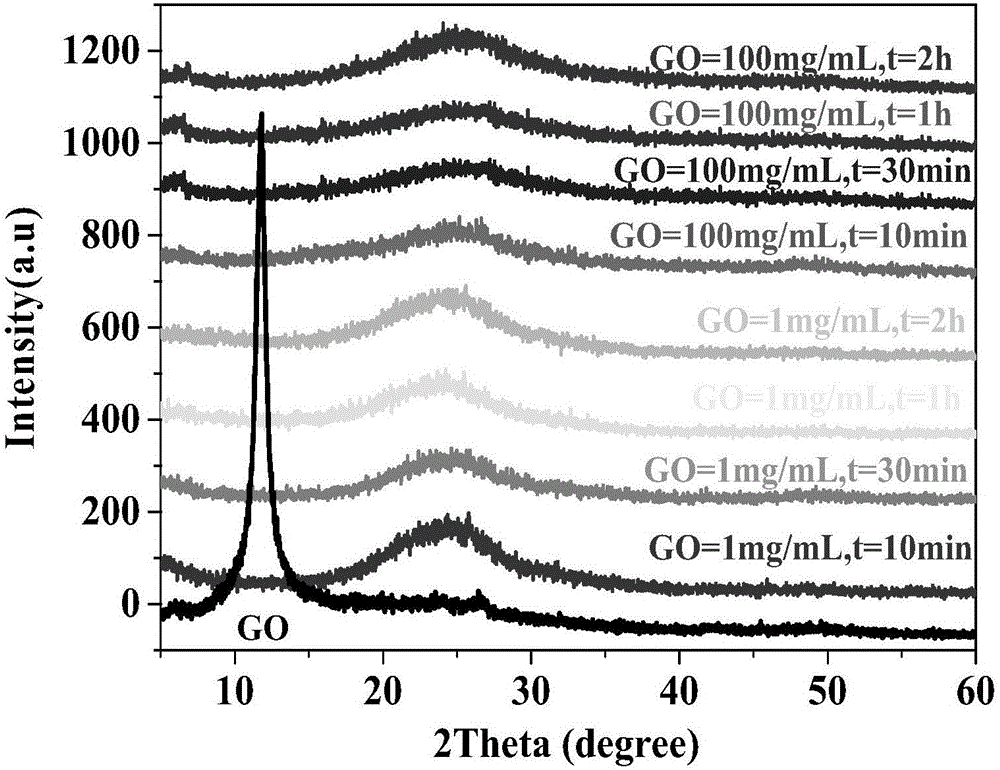

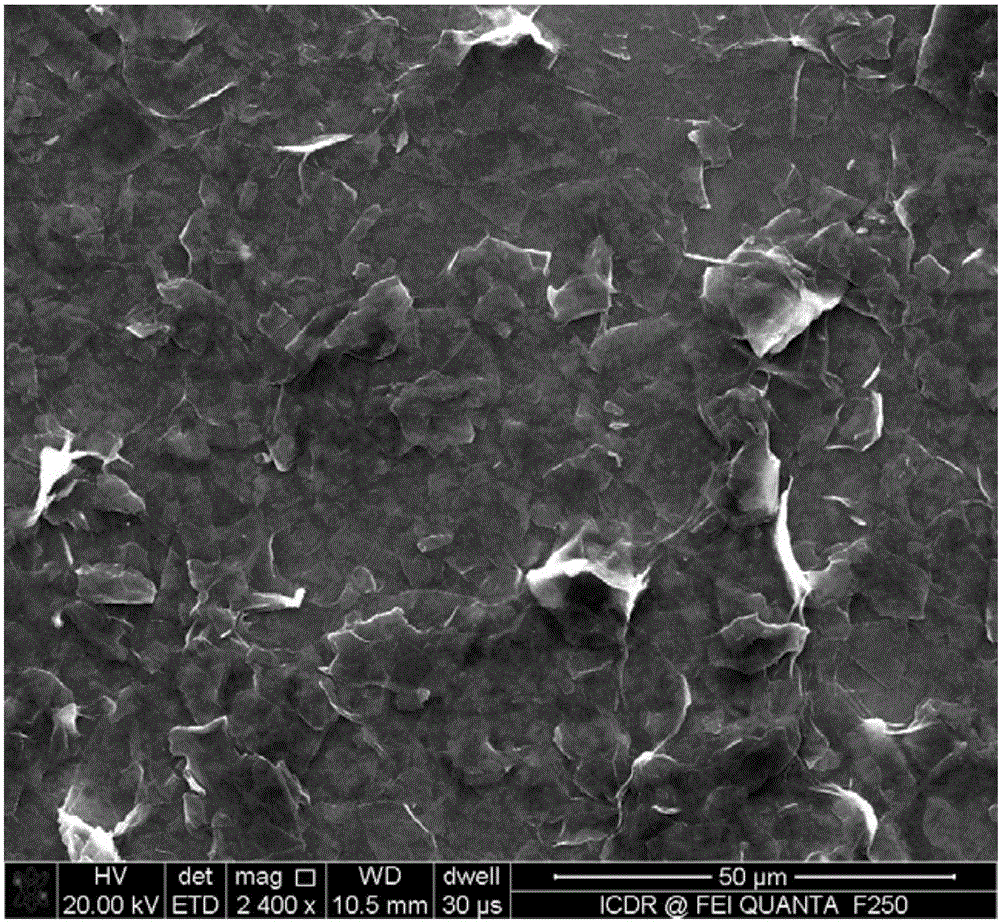

[0038] 0.1 g of graphite oxide was dissolved in 100 mL of deionized water, and the graphene oxide solution was obtained after ultrasonic peeling at a power of 560 W for 1 h, and 0.076 mL of concentrated sulfuric acid (mass concentration: 98%) was added to the graphene oxide solution. Finally, follow figure 1 , with a glassy carbon electrode as the positive electrode and a platinum wire as the negative electrode, a voltage of 1.5V was applied, and after stirring for 10 minutes, the reduced graphene was suction-filtered, and then fully washed with deionized water to adjust the pH value to neutral. sex. Subsequently, the graphene obtained after reduction cleaning is uniformly dispersed in deionized water by ultrasonic dispersion to form a stable high-quality graphene dispersion.

Embodiment 2

[0040] Different from Example 1, the reduction time is 30min.

Embodiment 3

[0042] The difference from Example 1 is that the reduction time is 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com