Limonite treatment system and application of limonite treatment system to limonite treatment

A limonite and fan-shaped technology is applied in the system field of processing limonite, which can solve the problems of increased construction cost, reduced product metallization rate, long process flow, etc., and achieves the effects of saving investment and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

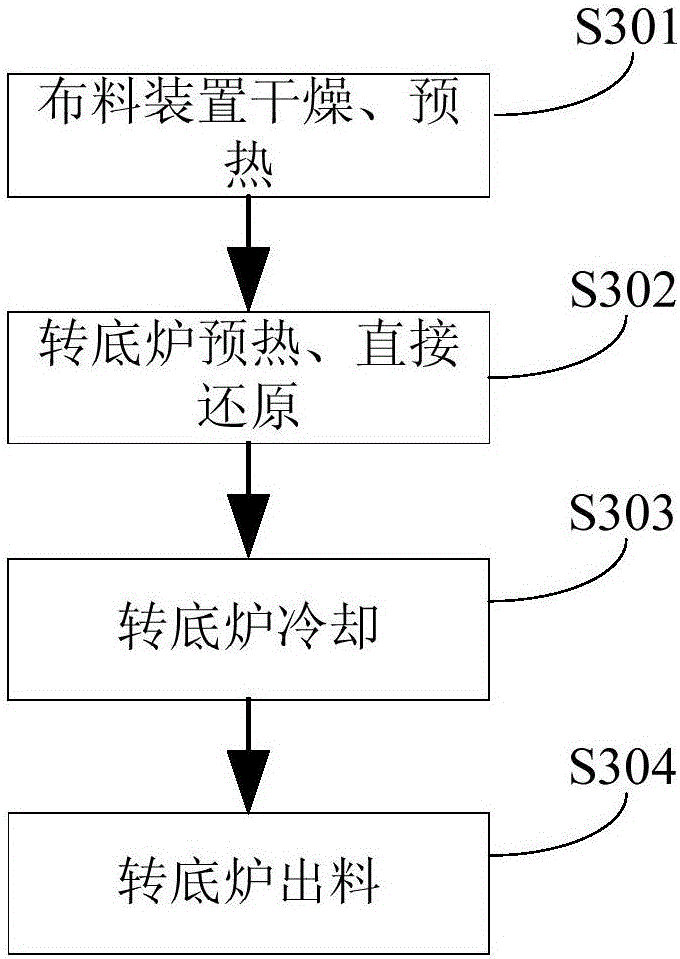

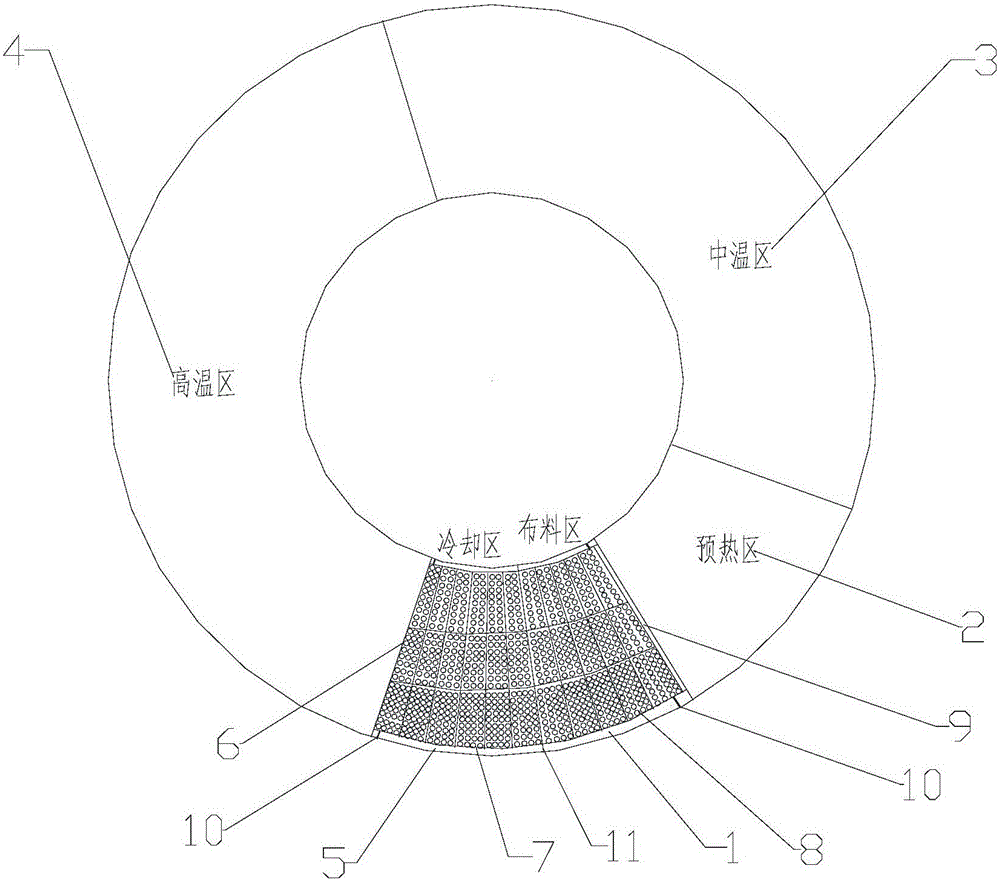

[0075] The limonite with an iron grade of 45.18% was crushed to -2 mm, and the tailings were magnetically separated under a magnetic field with a magnetic field strength of 250 mT to obtain qualified limonite. Qualified limonite is mixed with a certain amount of reducing agent, binder and additives, and then pressed into water-containing raw pellets with a particle size of 10mm and a free water content of 8%. The pellets are distributed into the Rotary hearth furnace. The distribution device is a mesh belt distributor, including a feeding channel, a three-layer mesh belt and a fixing device.

[0076] The distance between the centers of the mesh belts of each layer is 500mm, the height of the bottom mesh belt from the bottom of the rotary hearth furnace is 400mm, and the outlet of the bottom mesh belt is located above the material distribution area 1 of the rotary hearth furnace.

[0077] The inside of the mesh belt is divided into three circular runways by two partitions 7, a...

Embodiment 2

[0082] The limonite with an iron grade of 33.49% was crushed to -2 mm, and the tailings were magnetically separated under a magnetic field with a magnetic field strength of 250 mT to obtain qualified limonite. Qualified limonite is mixed with a certain amount of reducing agent, binder and additives, and then pressed into water-containing raw pellets with a particle size of 40mm and a free water content of 10%. The pellets are distributed into the Rotary hearth furnace. The distribution device is a mesh belt distributor, including a feeding channel, a three-layer mesh belt and a fixing device.

[0083] The distance between the centers of the mesh belts of each layer is 300mm, the height of the bottom mesh belt from the bottom of the rotary hearth furnace is 600mm, and the outlet of the bottom mesh belt is located above the material distribution area of the rotary hearth furnace.

[0084] The inside of the mesh belt is divided into 4 circular runways by three partitions, and ...

Embodiment 3

[0089] The limonite with an iron grade of 23.49% was crushed to -2 mm, and the tailings were magnetically separated under a magnetic field with a magnetic field strength of 250 mT to obtain qualified limonite. Qualified limonite is mixed with a certain amount of reducing agent, binder and additives, and then pressed into water-containing raw pellets with a particle size of 20mm and a free water content of 15%. The pellets are distributed into the Rotary hearth furnace. The distributing device is a mesh belt distributor, including a feeding channel 12, five layers of mesh belts 6 and a fixing device.

[0090] The distance between the centers of the mesh belts of each layer is 200mm, the height of the bottom mesh belt from the bottom of the rotary hearth furnace is 200mm, and the outlet of the bottom mesh belt is located above the material distribution area 1 of the rotary hearth furnace.

[0091] The inside of the mesh belt is divided into two ring-shaped tracks by partitions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com