Preparation method of master batch for graphene/PVC (Polyvinyl Chloride) composite material and master batch

A composite material and graphene technology, which is applied in the field of preparation of graphene/PVC composite material masterbatch, can solve problems such as unstable product quality, inability to fully disperse, and inability to continue production, and achieve improved mechanical properties, stable quality, The effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

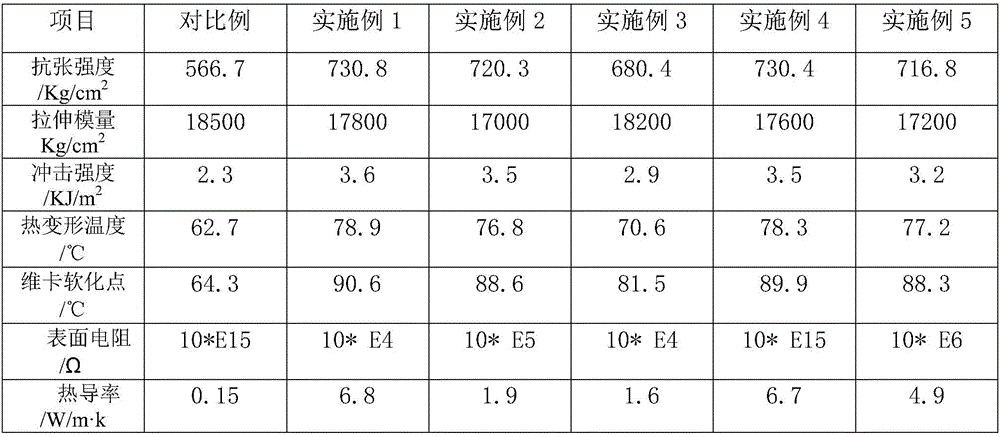

Examples

Embodiment 1

[0049] (1) Take the following masterbatch components by weight, 30kg graphene.

[0050] (2) Add the material weighed in step (1) into a high-speed dispersion mixing tank with an ultrasonic vibrating rod, and add 300 kg of tetrahydrofuran into the high-speed dispersion mixing tank, and perform stirring and ultrasonic dispersion for 6 hours.

[0051] (3) Weigh 150kg of PVC powder and add it into a closed stirring tank, add 1000kg of tetrahydrofuran at the same time, adjust the temperature to 46.5°C to completely dissolve PVC.

[0052] (4) Pump the mixed liquid prepared in step (2) (3) into a closed mixing tank with a volume of 2 cubic meters, and mix well for 1 hour.

[0053] (5) Pump the mixed liquid mixed in step (4) into the closed cycle spray drying equipment under airtight conditions, adjust the temperature of the air inlet to 100°C, and the temperature of the air outlet to 55°C. The bottom of the drying tower is discharged to prepare masterbatch powder particles suitable ...

Embodiment 2

[0056] (1) Take the following masterbatch components by weight, 5kg graphene, 10kg carbon nanotubes, and 10kg carbon fibers.

[0057] (2) Add the material taken in step (1) into a high-speed dispersion mixing tank with an ultrasonic vibrating rod, and add 200 kg of a mixed solution of dichloroethane, chloroform, and acetone to the high-speed dispersion mixing tank, and stir and ultrasonically Disperse for 4 hours.

[0058] (3) Weigh 150kg of PVC powder and add it to a closed mixing tank, add 800kg of dichloroethane, chloroform, and acetone mixture at the same time, and adjust the temperature to 40°C to completely dissolve PVC.

[0059] (4) Pump the mixed liquid prepared in step (2) (3) into a closed mixing tank with a volume of 2 cubic meters, and mix well for 1 hour.

[0060] (5) Pump the mixed liquid mixed in step (4) into the closed cycle spray drying equipment under airtight conditions, adjust the temperature of the air inlet to 100°C, and the temperature of the air outle...

Embodiment 3

[0063] (1) Take the following masterbatch components by weight, 5kg graphene, 1kg carbon nanotube, 30kg carbon black.

[0064] (2) Add the material weighed in step (1) into a high-speed dispersion mixing tank with an ultrasonic vibrating rod, and add 400 kg of acetone and carbon disulfide mixed solution to the high-speed dispersion mixing tank, and stir and ultrasonically disperse for 4 hours.

[0065] (3) Weigh 150kg of PVC powder and add it to a closed mixing tank, add 900kg of acetone and carbon disulfide mixture at the same time, and adjust the temperature to 45°C to completely dissolve the PVC.

[0066] (4) Pump the mixed liquid prepared in steps (2) and (3) into a closed stirring tank with a volume of 2 cubic meters, and mix well for 0.5 hours.

[0067] (5) Pump the mixed liquid mixed in step (4) into the closed cycle spray drying equipment under airtight conditions, adjust the temperature of the air inlet to 100°C, and the temperature of the air outlet to 40°C. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com