A kind of low-density cement slurry system for deep water surface layer cementing and its application

A technology of cement slurry and low density, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large amount of hollow microspheres, low cement slurry production rate, huge construction workload, etc., and achieve high performance Easy to adjust, convenient on-site construction, good pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

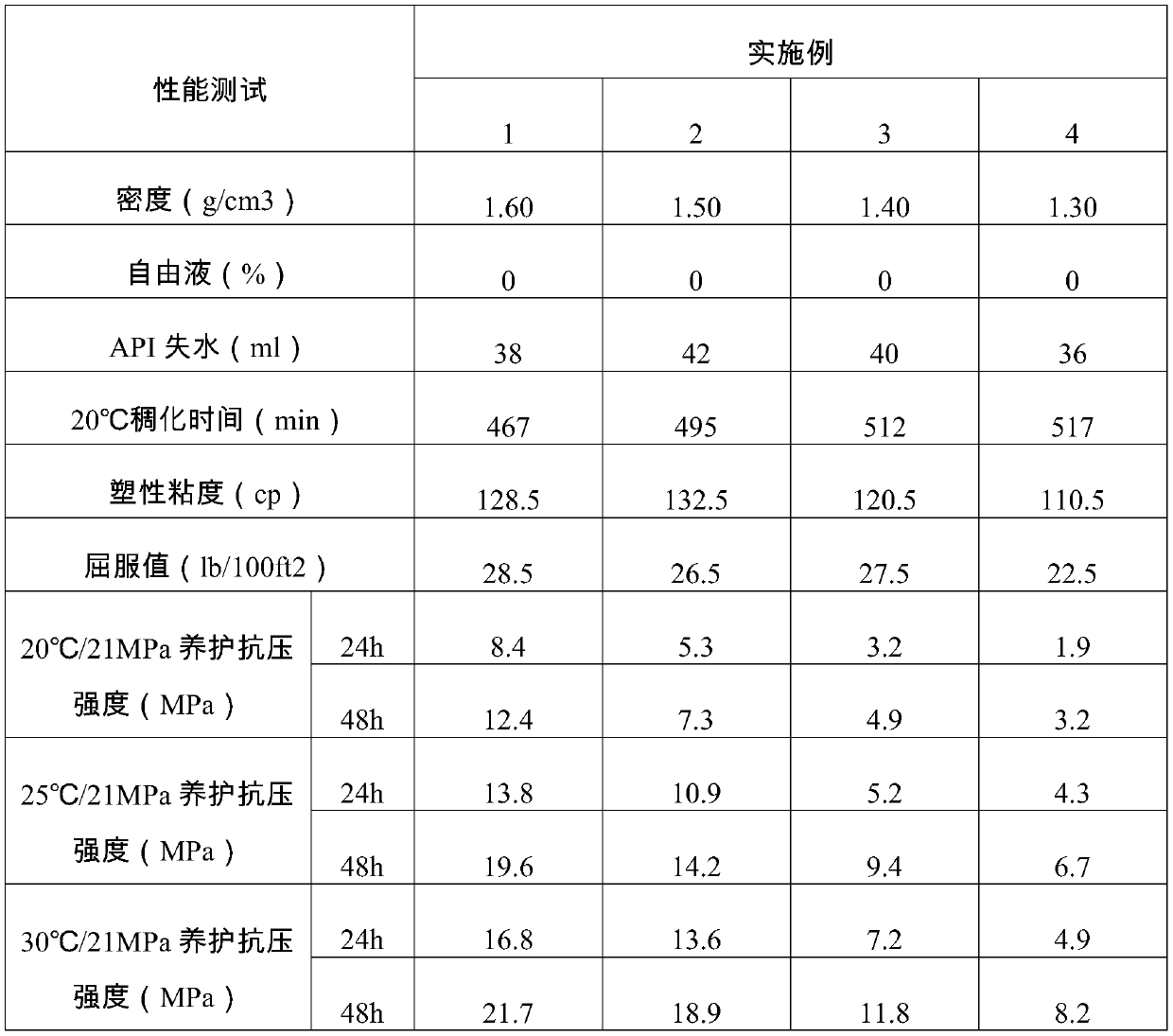

Examples

Embodiment 1

[0036] Preparation of liquid suspension:

[0037] Weigh and mix 50g of silicon dioxide liquid LUDOX HS 40, 15g of polyurethane suspending agent ACRYSOL RM-8W, and 35g of deionized water, and stir evenly to obtain a liquid suspending agent. Among them, the particle size of silicon dioxide in LUDOX HS40 is 12nm, the content is 40%, and pH=9.5.

[0038] Preparation of liquid early strength agent:

[0039] Nano Ca(OH) 2 Preparation of:

[0040] (1) Weigh 11.1g of calcium chloride and 40g of deionized water, place them in a beaker and stir to dissolve them, and place them in a water bath at 60°C after they are completely dissolved;

[0041] (2) add 4g polycarboxylate dispersant in beaker, stir;

[0042] (3) Weigh 10 g of sodium hydroxide and dissolve it in 20 g of deionized water, put it into the dropping funnel after it is completely dissolved, add the sodium hydroxide solution into the beaker in a dropwise manner, and stir while adding it dropwise.

[0043] (4) Suction filtr...

Embodiment 2

[0057] Preparation of liquid suspension:

[0058] Weigh and mix 50g of silicon dioxide liquid LUDOX AS 40, 20g of polyurethane suspending agent ACRYSOL RM-8W, and 30g of deionized water, and stir evenly to obtain a liquid suspending agent. Among them, the particle size of silicon dioxide in LUDOX AS 40 is 22nm, the content is 40%, and the pH=9.4.

[0059] Preparation of liquid early strength agent:

[0060] (1) Weigh 1.38g xanthan gum, slowly add it into a beaker filled with 100g deionized water, and stir for 1h to form a uniform viscous solution;

[0061] (2) Weigh 142g K 2 SO 4 and 148g Na 2 SO 4 and 16g Na 2 SiO 3 , added to 80g of ethylene glycol, stirred to disperse evenly;

[0062] (3) Weigh 80g of the solution obtained in step (1) and add it to the liquid obtained in step (2), and stir to make it evenly mixed;

[0063] (4) Add the nano-Ca(OH) prepared by 28g embodiment 1 2 , stir to make it evenly mixed;

[0064] (5) Add 7.2g triethanolamine, stir to make it ...

Embodiment 3

[0071] Preparation of liquid suspension:

[0072] Weigh and mix 55g of silicon dioxide liquid LUDOX SM 30, 25g of polyurethane suspending agent ACRYSOL RM-2020W, and 20g of deionized water, and stir evenly to obtain a liquid suspending agent. Among them, the particle size of silicon dioxide in LUDOX SM30 is 7nm, the content is 30%, pH=10.

[0073] Preparation of liquid early strength agent:

[0074] (1) Weigh 1.2g xanthan gum, slowly add it into a beaker filled with 100g deionized water, and stir for 1h to form a uniform viscous solution;

[0075] (2) Weigh 160g Na 2 SO 4 and 3g Na 2 SiO 3 , added to 50g of ethylene glycol, stirred to disperse evenly;

[0076] (3) Weigh 50g of the solution obtained in step (1) and add it to the liquid obtained in step (2), and stir to make it evenly mixed;

[0077] (4) add the nano-Ca(OH) that 20g embodiment 1 prepares 2 , stir to make it evenly mixed;

[0078] (5) Add 3.8g triethanolamine, stir to make it mix evenly;

[0079] (6) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com