A kind of preparation method of polymer fluid loss reducing agent for sulphoaluminate cement

A technology of sulphoaluminate cement and water loss reducing agent, which is applied in the field of oil and gas well cementing, can solve the problems of construction slurry mixing risk, difficult density control, poor stability of cement slurry, etc., and achieve effective control of water loss and good stability , the effect of easy thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

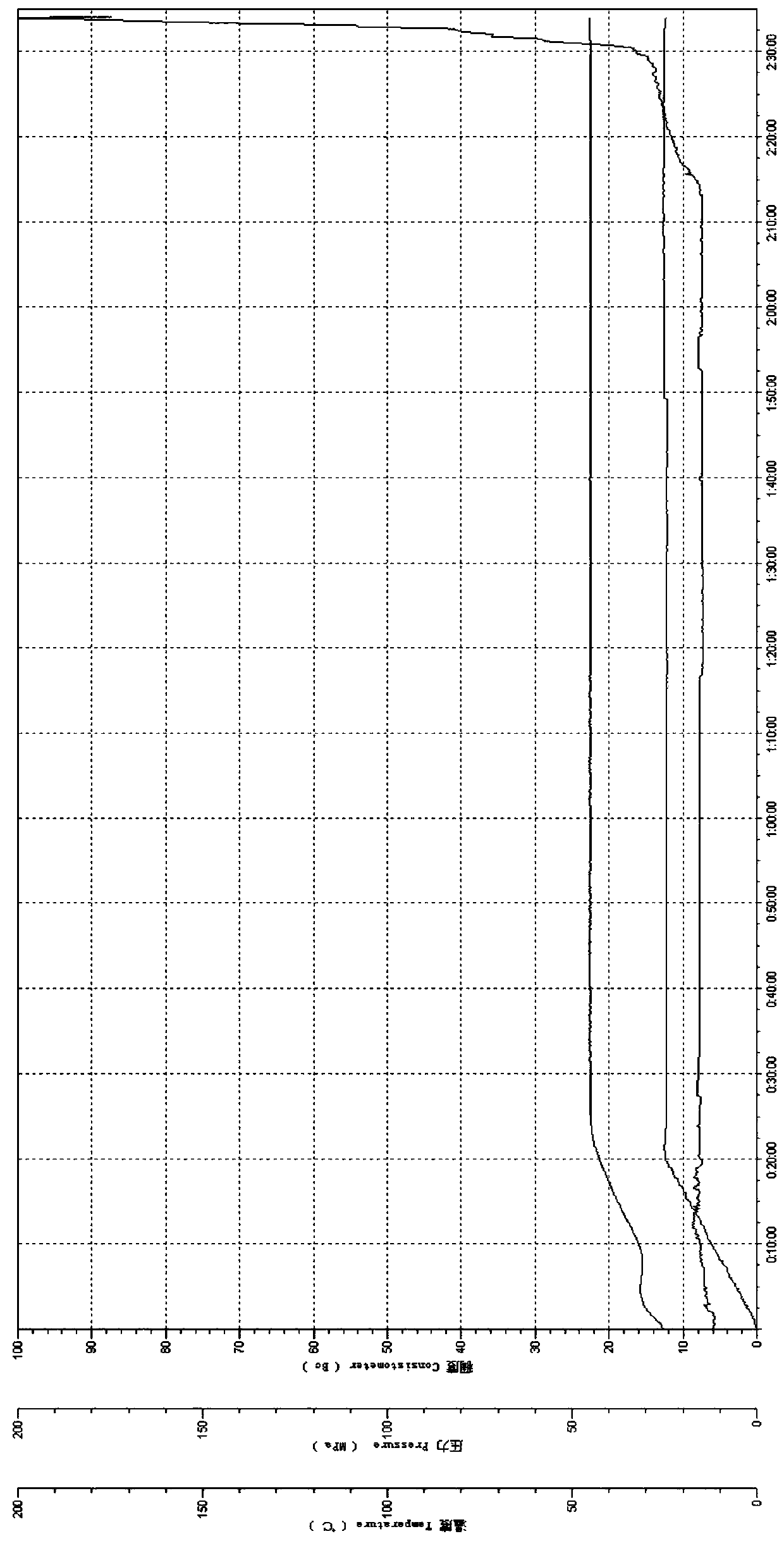

Image

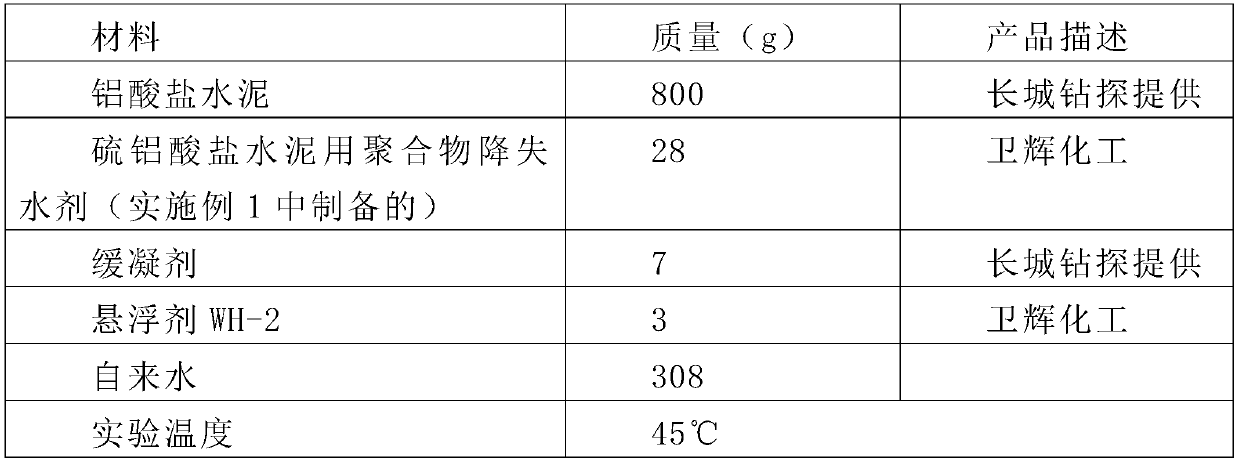

Examples

Embodiment 1

[0025] A preparation method of a polymer fluid loss reducer for sulphoaluminate cement, comprising the steps of:

[0026] (1) Modified polymerization of nanomaterials to obtain modified nanomaterials;

[0027] The nanomaterial is a nano-silica solution, and the modified polymerization includes the following steps: (1-1) 2.4 kg of a silane coupling agent is added dropwise to 477.6 kg of a nano-silica solution, and in the nano-silica solution, the nano-silica The mass fraction of silicon oxide is 29wt%, and the amount of silane coupling agent added to the nano-silica solution is 0.5-1wt% of the mass of the nano-silica solution, and the silane coupling agent / silica sol mixed system is formed after stirring and mixing for 30 minutes After continuing to stir, the initial silane coupling agent modified silica sol is obtained; (1-2) the initial silane coupling agent modified silica sol is adjusted to pH 10 with sodium hydroxide solution, and the concentration of sodium hydroxide solu...

Embodiment 2

[0034] A preparation method of a polymer fluid loss reducer for sulphoaluminate cement, comprising the steps of:

[0035] (1) Modified polymerization of nanomaterials to obtain modified nanomaterials;

[0036] The nanomaterial is a nano-silica solution, and the modified polymerization includes the following steps: (1-1) 2.4 kg of a silane coupling agent is added dropwise to 477.6 kg of a nano-silica solution, and in the nano-silica solution, the nano-silica The mass fraction of silicon oxide is 30wt%, and the amount of silane coupling agent added to the nano-silica solution is 0.5-1wt% of the mass of the nano-silica solution, and the silane coupling agent / silica sol mixed system is formed after stirring and mixing for 30 minutes After continuing to stir, the initial silane coupling agent modified silica sol is obtained; (1-2) the initial silane coupling agent modified silica sol is adjusted to pH 10 with sodium hydroxide solution, and the concentration of sodium hydroxide solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com