Preparation method of porous-graded sphere activated copper oxide powder

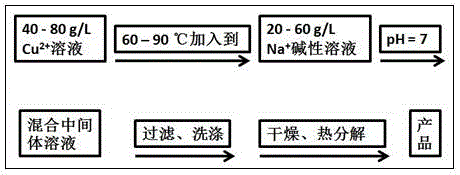

An active copper oxide, graded technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of increasing process difficulty and wastewater treatment difficulty, complicated solution preparation, complicated equipment and process, etc., and the reaction end point is easy to control and process Simple operation and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 107.2g CuCl 2 ·H 2 O was dissolved in pure water to make a 1L solution (Cu 2+ Concentration is 40g / L), weigh 106gNaHCO 3 Dissolve in pure water to make 1.2L solution (Na + ion concentration 24.5g / L), the NaHCO 3 Add the solution into a 3L beaker, stir it mechanically, preheat to 85°C and keep the reaction temperature, add CuCl 2 Solution, added within 30min, pH=7. Aging for half an hour.

[0043] Suction filtration, 50mL pure water washing 3 times.

[0044] The washed powder is dried and thermally decomposed to obtain porous graded spherical activated copper oxide.

[0045] The drying temperature is 120°C, and the thermal decomposition temperature is 400°C.

Embodiment 2

[0047] Weigh 266.4g Cu(NO 3 ) 2 ·3H 2 O was dissolved in pure water to make a 1L solution (Cu 2+ Concentration is 70g / L), weigh 118.5gNa 2 CO 3 Dissolve in pure water to make 1.2L solution (Na + ion concentration 43g / L), the Na 2 CO 3 Add the solution into a 3L beaker, stir it mechanically, preheat to 75°C and keep the reaction temperature, add Cu(NO 3 ) 2 Solution, added within 30min, pH=7. Aging for half an hour.

[0048] Suction filtration, 50mL pure water washing 3 times.

[0049] The washed powder is dried and thermally decomposed to obtain porous graded spherical activated copper oxide.

[0050] The drying temperature is 120°C, and the thermal decomposition temperature is 400°C.

Embodiment 3

[0052] Weigh 236g Cu(SO 4 ) 2 ·5H 2 O was dissolved in pure water to make a 1L solution (Cu 2+ Concentration is 60g / L), take by weighing 19.2g sodium hydroxide and 51.2g Na respectively 2 CO 3 Dissolve in pure water to make 1.2L solution (Na + ion concentration of 36.8g / L), the above-mentioned alkaline mixed solution was added to a 3L beaker, mechanically stirred, preheated to 65°C and kept at the reaction temperature, adding Cu(SO 4 ) 2 Solution, added within 30min, pH=7. Aging for half an hour.

[0053] Suction filtration, 50mL pure water washing 3 times.

[0054] The washed powder is dried and thermally decomposed to obtain porous graded spherical activated copper oxide.

[0055] The drying temperature is 120°C, and the thermal decomposition temperature is 400°C.

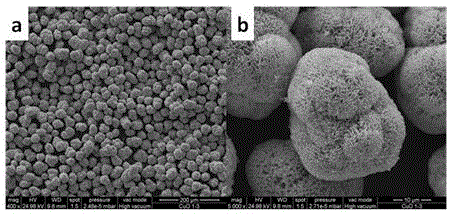

[0056] see figure 2 , which is the SEM picture of the best embodiment 2, as can be seen from the figure, the product appearance is a microrod (diameter 500nm, length 2μm, such as figure 2 Shown in b) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com