A method of producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate

A technology of lithium hydroxide and lithium carbonate, which is applied in the direction of lithium oxide; The effect of guaranteeing product quality, ensuring quality, and reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

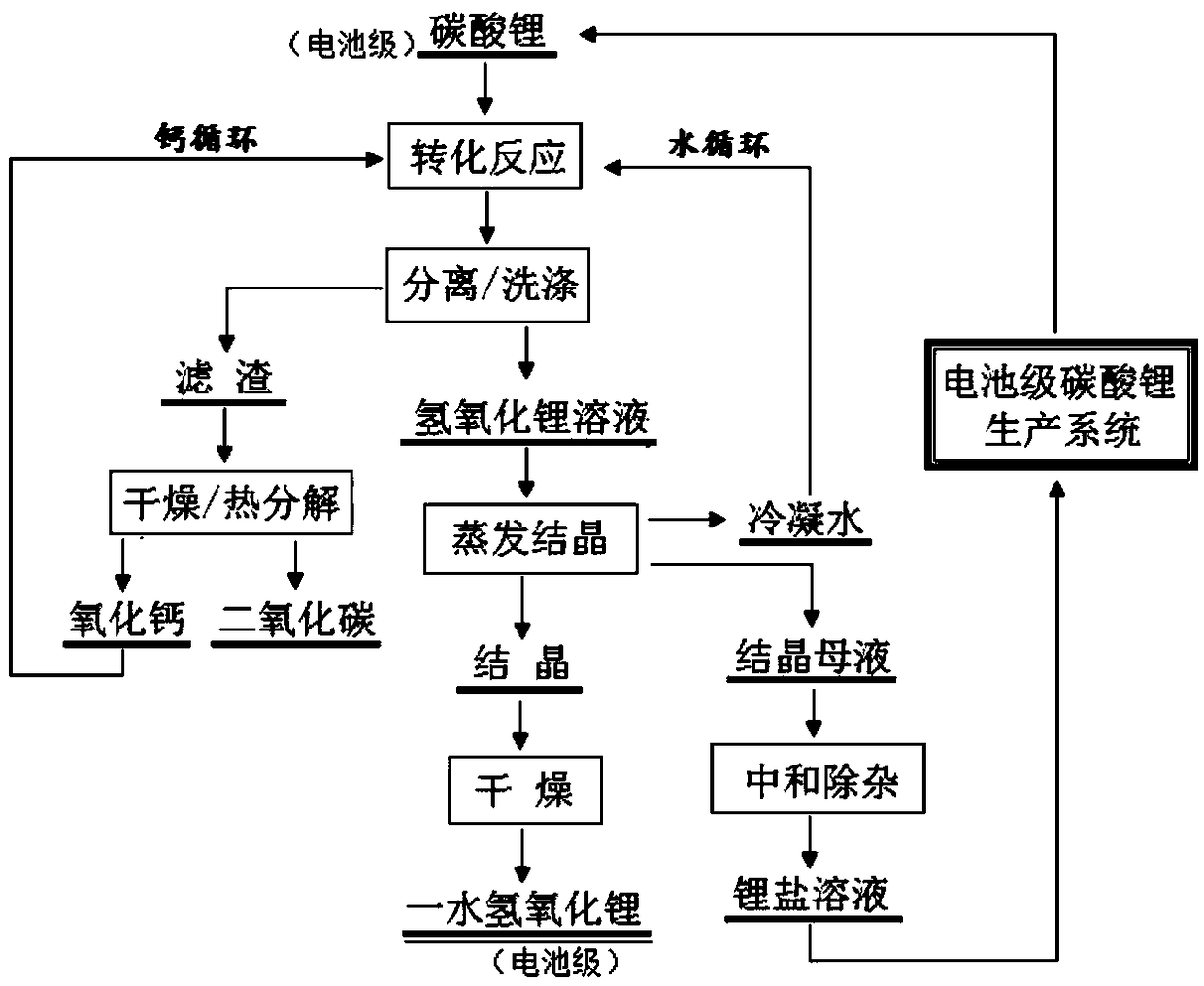

[0024] Embodiment 1 A method of producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate

[0025] 1) Transformation reaction: add calcium oxide and water to lithium carbonate at a weight ratio of 1:0.7:18, and a transformation reaction occurs at 80°C for 7 hours to generate transformation slag and lithium hydroxide solution. The conversion rate is 91.1%. The concentration is 3.49%.

[0026] 2) Separation and washing: separating the reacted conversion slag from the lithium hydroxide solution, washing the conversion slag, and incorporating the washing solution into the lithium hydroxide solution.

[0027] 3) drying the conversion slag obtained in step 2), and the generated calcium oxide enters the calcium cycle to participate in the conversion reaction of step 1) again;

[0028] 4) Evaporate, crystallize and dry the lithium hydroxide solution obtained in step 2) to obtain lithium hydroxide monohydrate; the condensed water generated during the c...

Embodiment 2

[0030] Embodiment 2 A method of producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate

[0031] 1) Conversion reaction: add calcium oxide and water to lithium carbonate at a weight ratio of 1:0.75:18.7, and a conversion reaction occurs at 85°C for 5.5 hours to generate conversion slag and lithium hydroxide solution. The conversion rate is 98.5%. Lithium hydroxide The concentration is 3.45%.

[0032] 2) Separation and washing: separating the reacted conversion slag from the lithium hydroxide solution, washing the conversion slag, and incorporating the washing solution into the lithium hydroxide solution.

[0033] 3) drying the conversion slag obtained in step 2), and the generated calcium oxide enters the calcium cycle to participate in the conversion reaction of step 1) again;

[0034] 4) Evaporate, crystallize and dry the lithium hydroxide solution obtained in step 2) to obtain lithium hydroxide monohydrate; the condensed water generated d...

Embodiment 3

[0036] Embodiment 3 A method of producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate

[0037] 1) Conversion reaction: add calcium oxide and water to lithium carbonate at a weight ratio of 1:0.72:20, and a conversion reaction occurs at 80°C for 6.5 hours to generate conversion slag and lithium hydroxide solution. The conversion rate is 93.3%. The concentration of lithium is 3.43%.

[0038] 2) Separation and washing: separating the reacted conversion slag from the lithium hydroxide solution, washing the conversion slag, and incorporating the washing solution into the lithium hydroxide solution.

[0039] 3) drying the conversion slag obtained in step 2), and the generated calcium oxide enters the calcium cycle to participate in the conversion reaction of step 1) again;

[0040] 4) Evaporate, crystallize and dry the lithium hydroxide solution obtained in step 2) to obtain lithium hydroxide monohydrate; the condensed water generated during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com