3D printing device applicable to pneumatic extruding low-temperature platform control

A platform control and 3D printing technology, which is applied in the field of tissue engineering technology and biological 3D printing, can solve the problems such as difficult to meet the requirements of the working environment, and achieve the effect of novel structure, easy control and good molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

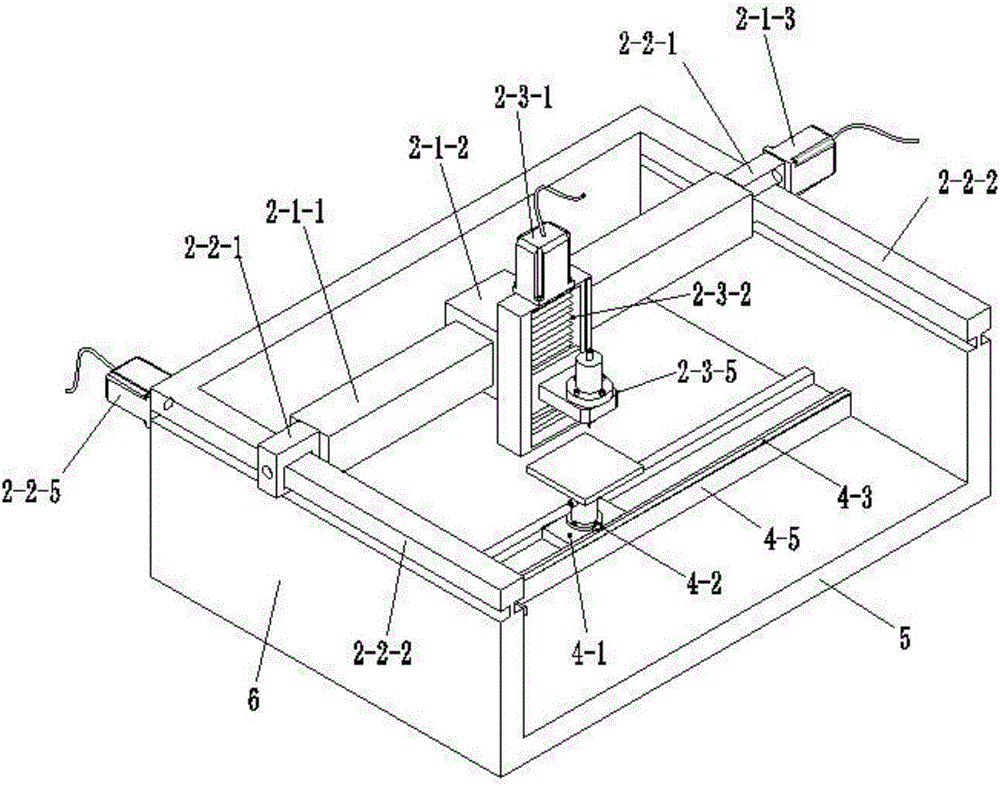

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1-2 As shown, a 3D printing device suitable for pneumatic extrusion low-temperature platform control, including a bottom plate 5 and a side plate 6, the forming system is also composed of a nozzle device 1, a three-dimensional motion mechanism 2, a forming table cooling device 3 and a forming table control mechanism 4 Composition; the nozzle device 1 is composed of the upper terminal air port 1-1, the screw group 1-2, the barrel 1-3 and the needle head 1-4; the three-dimensional motion mechanism 2 is composed of the X-axis motion mechanism 2-1, and the Y-axis motion mechanism 2- 2 and Z-axis motion mechanism 2-3; X-axis motion mechanism 2-1 is composed of beam 2-1-1, X-axis motion slider 2-1-2 and X-axis control motor 2-1-3; Y-axis The motion mechanism 2-2 consists of a Y-axis motion slider 2-2-1, a guide rail 2-2-2, a Y-axis grating 2-2-3, a Y-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com