Automatic welding technique for splicing plates of cylinder body of oil tank truck

An automatic welding and oil tanker technology, applied in manufacturing tools, welding equipment, metal processing, etc., can solve the problems of large welding heat input, difficult cleaning of sundries, oil pollution, poor gas protection on the back, etc., to ensure the quality of welding seam , The effect of eliminating the welding defects of chain pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, rather than for limiting the protection scope of the present invention.

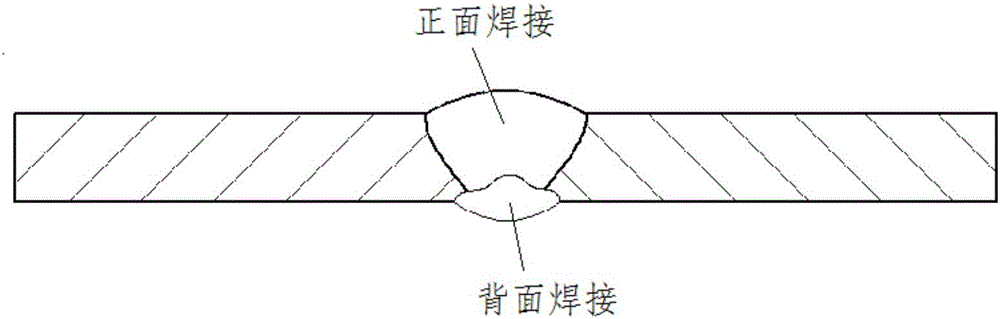

[0019] An automatic welding process for assembling a tank body of an oil tanker in this embodiment adopts automatic TIG welding, and the welding seam layer distribution of the welded joint is as follows figure 1 shown, including the following steps:

[0020] I. Front welding: Front penetration welding to double-sided forming is adopted for the joints of the splicing plate and ring of the cylinder body. The welding parameters: the traveling speed of the welding trolley is 215mm / min, Ih: 410A, Il: 330A, Ic: 325A, U: 17.2 v, wfs: 220cm / min, F: 1.3HZ, Fac: 54HZ, N: 70%, Nac: 70%, gas flow: 25L / min;

[0021] II. Back welding: after the completion of step I, turn over the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com