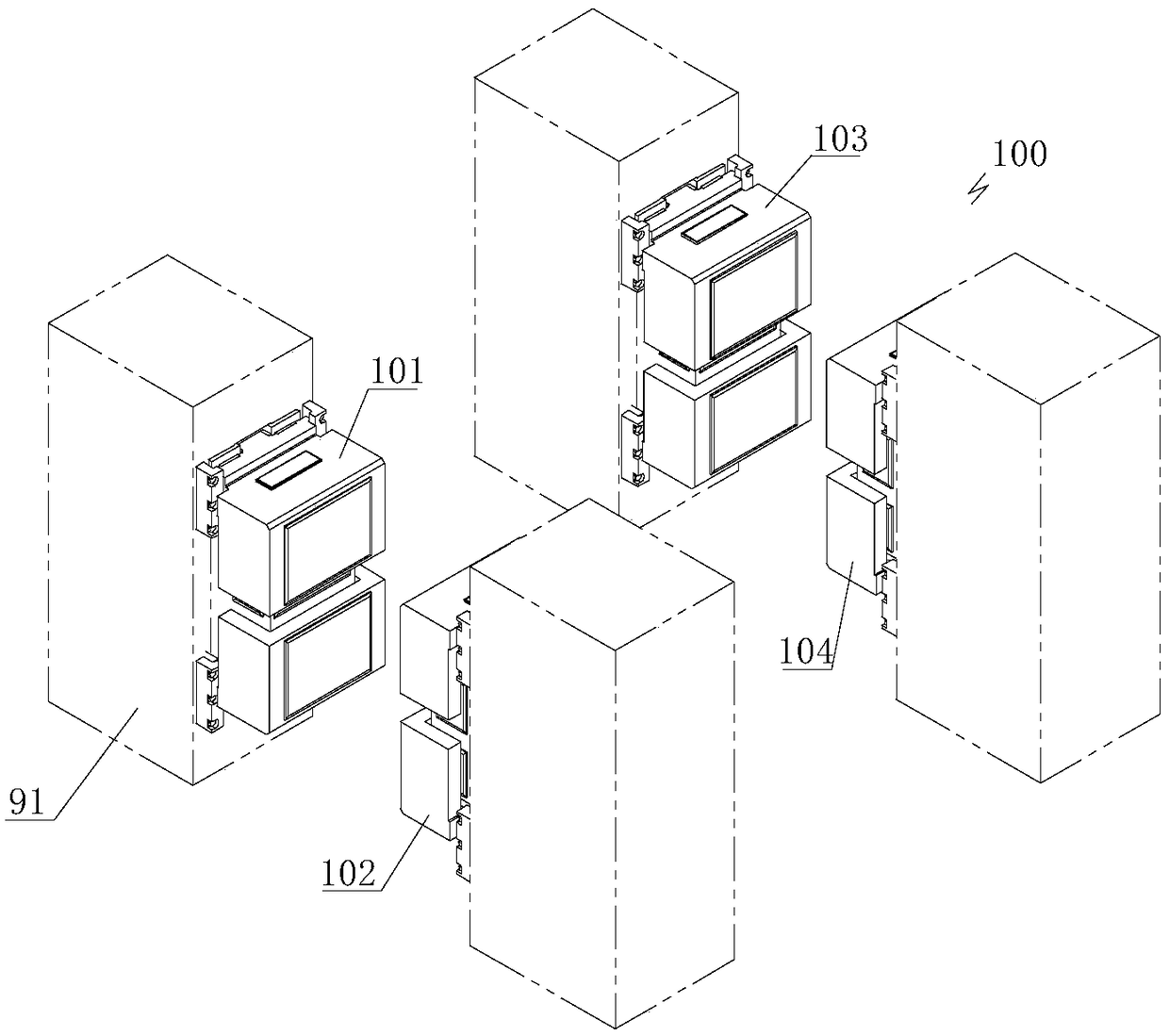

Double-guided work roll bending and balancing device for strip mill

A work roll bending and balancing device technology, applied in rolling force/roll gap control, keeping roll equipment in an effective state, metal rolling, etc. Oil and other problems, to avoid rust, convenient and convenient disassembly and assembly, and improve work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

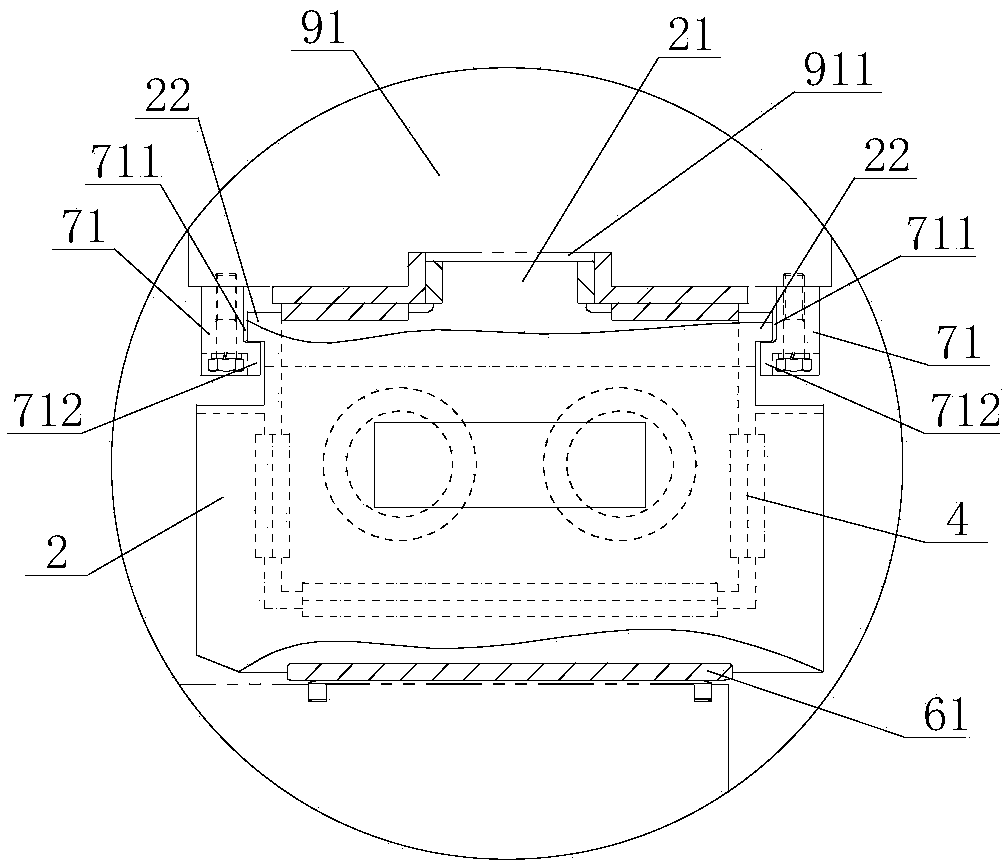

[0057] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0058] Such as Figure 1 to Figure 5 As shown, the present invention provides a double-guided work roll bending and balancing device 100 for a strip mill, comprising a bending roll and a balancing cylinder 1, and a cylinder body 11 of the bending roll and balancing cylinder is fixedly arranged on the inner wall of the archway 91. The top of the body 11 is from top to bottom, and the upper piston rod 12 is installed for sealing and sliding. The bottom of the cylinder body 11 is from bottom to top, and the lower piston rod 13 is for sealing and sliding. There is a hydraulic system for controlling the actions of the upper piston rod 12 and the lower piston rod 13 (the hydraulic system is controlled by the control device, which is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com