Large-size rectangular steel production process combining billeting, continuous rolling and controlled cooling

A production process and technology for rectangular steel, applied in cooling beds, metal rolling, manufacturing tools, etc., can solve the problems of low production process cost, unavailability of rectangular steel, bending and twisting of rectangular steel, etc., and achieve the cost of production process. Low, high precision control of external dimensions, the effect of enriching production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Φ500mm section continuous casting round billet production 260 tons, F300X110, the specific process is as follows:

[0037] 1) Heating: The blank is sent to the heating furnace through the conveying roller table for heating. The heating furnace is an air and gas double regenerative heating furnace, and the furnace is a double-row cloth distribution. The heating time is 7-8 hours, and the steel billet is tapped after reaching the tapping temperature, and the tapping temperature is controlled at 1100-1150°C.

[0038] 2) High-pressure water descaling machine: Segmented annular high-pressure descaling machine removes iron oxide chips on the surface of the billet. The pressure of the descaling machine is 23MPa, and the descaling speed is 0.8m / s.

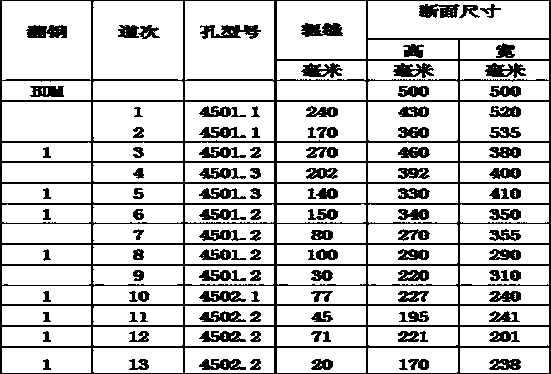

[0039] 3) Rolling by the blanking machine: the blanking machine is a double-roller reciprocating blanking machine, and the diameter of the rolls is Ф1200mm. After the large round billet is rolled by the blanking machine for 13 passe...

Embodiment 2

[0051] The Φ500mm section continuous casting round billet produces 450 tons of 180X115, hot delivery for billet rolling, the specific process is as follows:

[0052] 1) Heating: The blank is sent to the heating furnace through the conveying roller table for heating. The heating furnace is an air and gas double regenerative heating furnace, and the furnace is a double-row cloth distribution. The heating time is 7~8 hours. The steel billet is tapped after reaching the tapping temperature, and the tapping temperature is controlled at 1100~1150°C.

[0053] 2) High-pressure water descaling machine: Segmented annular high-pressure descaling machine removes iron oxide chips on the surface of the billet. The pressure of the descaling machine is 230bar, and the descaling speed is 0.8m / s.

[0054] 3) Rolling by the blanking machine: the blanking machine is a double-roller reciprocating blanking machine, and the diameter of the rolls is Ф1200mm. After the large round billet is rolled by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com