secondary cyclone separator

A technology of cyclone separator and separator, which is applied in the direction of cyclone device and the device whose axial direction of the cyclone can be reversed, etc. It can solve the problems that the performance of the secondary cyclone impurity removal equipment is not fully exerted and the production efficiency is limited. , to achieve the effects of meeting insufficient production needs, improving production efficiency, and diversifying production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

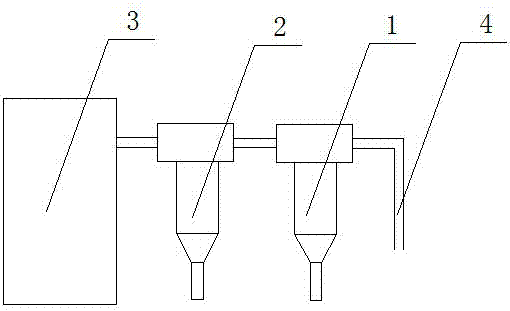

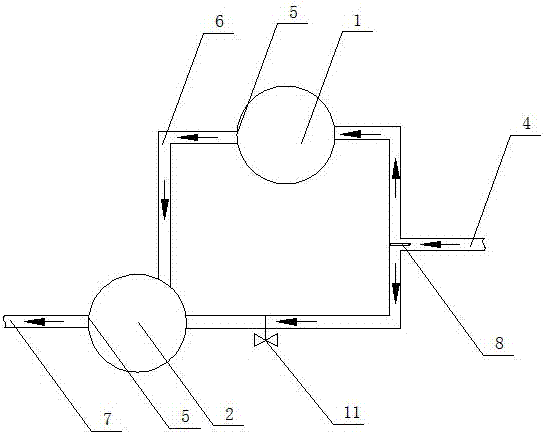

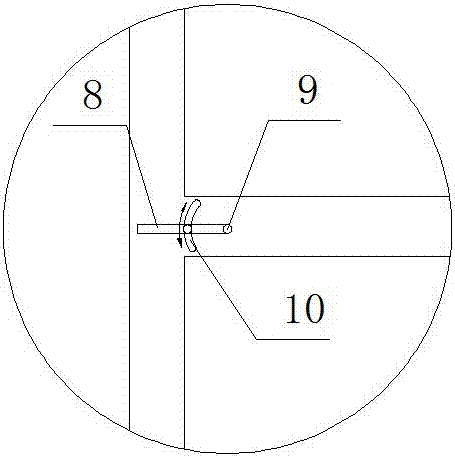

[0016] figure 1 and 2 A secondary cyclone separator shown includes a primary separator 1, a secondary separator 2 and a hopper 3, and the primary separator 1 and secondary separator 2 are respectively communicated with the feeding pipe 4, and the primary separation The discharge port 5 of the device 1 communicates with the secondary separator 2 through the connecting pipe 6 , and the discharge port 12 of the secondary separator 2 communicates with the discharge pipe 7 . An air distribution plate 8 is provided on the feeding pipe 4 . One end of the air distribution plate 8 is provided with a rotating shaft 9, and the rotating shaft 9 is connected with the wall of the feeding pipe 4. The feeding pipe 4 is provided with an indexing plate 10, and the angle of the air dividing plate 8 can be adjusted along the indexing plate 10. The feed pipe 4 of the secondary separator 2 is provided with a valve 11 .

[0017] When it is necessary to improve production efficiency during product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com