Automatic refrigerator refrigerating tube cleaning device and method

A technology for automatic cleaning and cleaning devices, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems that the capillary can not ensure the drying of the inner wall, increase the cost of replacing the capillary, and shorten the service life of the refrigerator. The human-computer interaction is reliable and stable, easy to promote and use, and the effect of eliminating the need for replacement links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

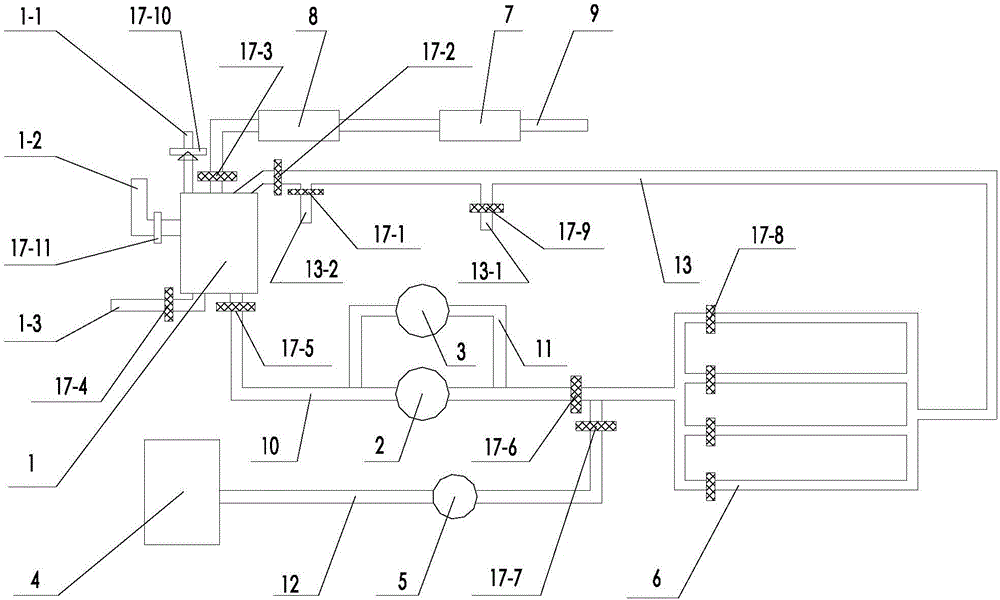

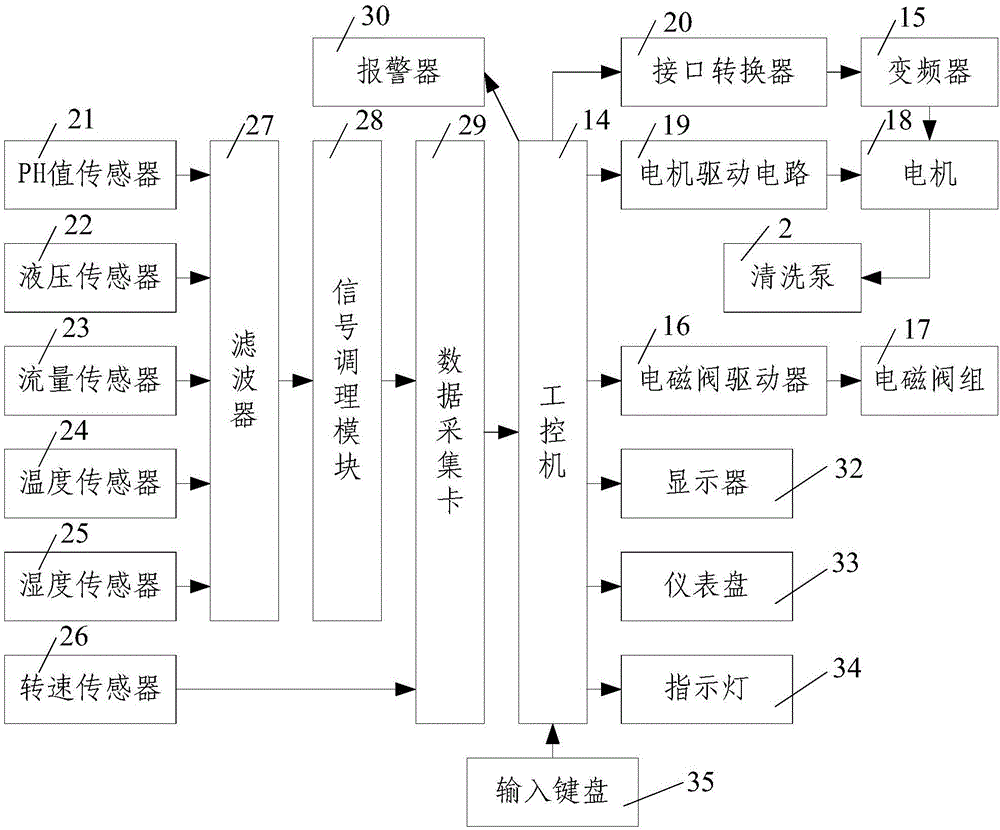

[0063] Such as figure 1 and figure 2 As shown, the refrigerator refrigeration pipe automatic cleaning device according to the present invention includes a cleaning device and a control terminal for controlling the operation of the cleaning device. The cleaning device includes a cleaning pipeline communicated with the capillary tube 6 of the refrigerator and a Both are in communication with the liquid storage tank 1 for storing the cleaning liquid and the nitrogen source 4 for storing nitrogen. 1 and the liquid inlet pipe 10 and the liquid outlet pipe 13 of the refrigerator capillary 6, the heat exchanger 5 and the air inlet valve 17-7 are installed on the inlet pipe 12, the cleaning pump 2 is installed on the liquid inlet pipe 10 and the cleaning pump 2 The on-off valve 17-5 and the liquid inlet valve 17-6 on both sides, the waste liquid recovery pipe 13-1 and the waste water discharge pipe 13-2 are arranged on the liquid outlet pipe 13, and the position of the liquid outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com