A kind of automatic processing and production equipment for motor rotor

A technology for motor rotors and production equipment, applied in the manufacture of stator/rotor bodies, conveyors, transportation and packaging, etc., can solve the problems of machining accuracy, complex structure, time-consuming and labor-intensive, etc., to improve the quality of use and easy operation. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

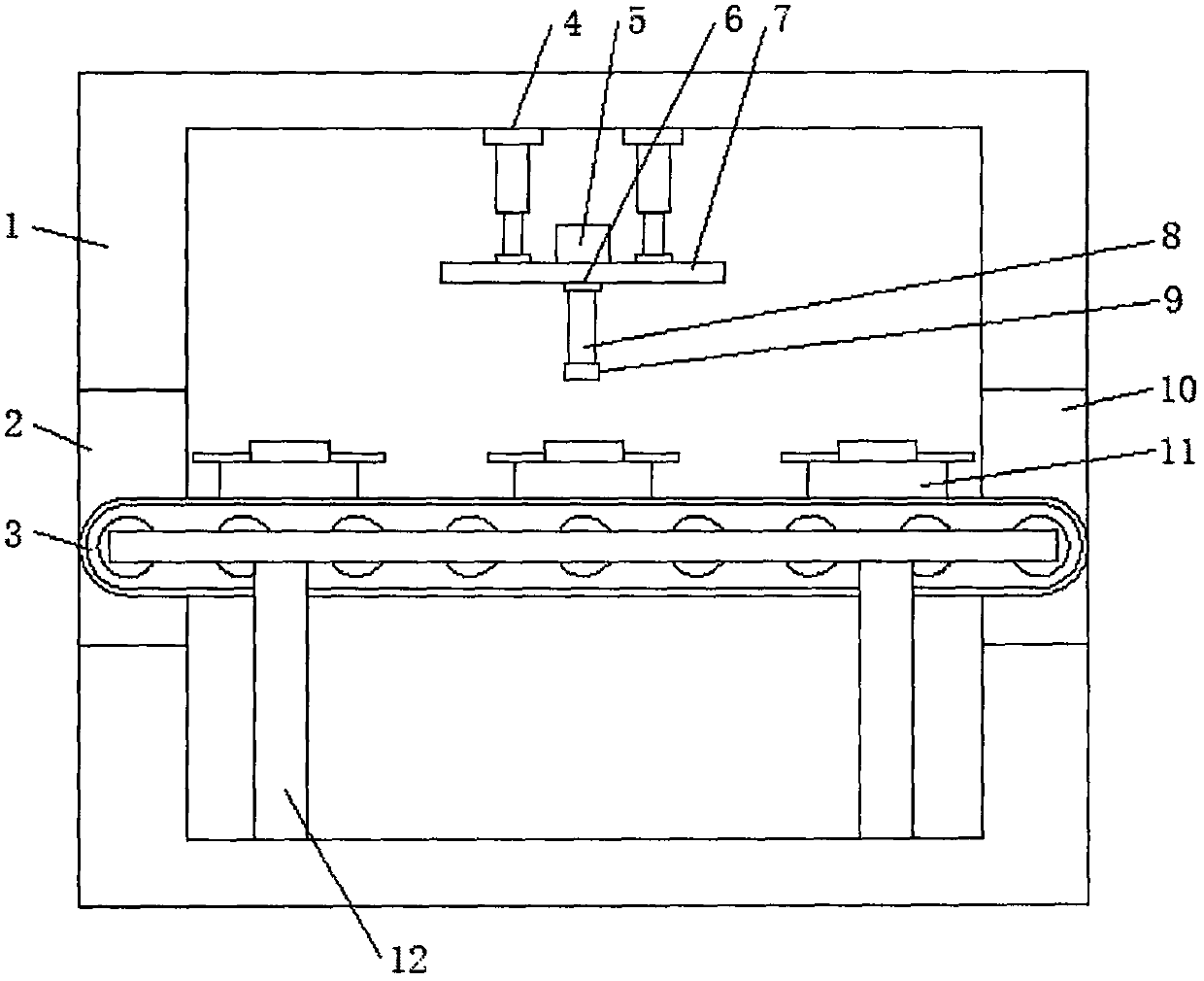

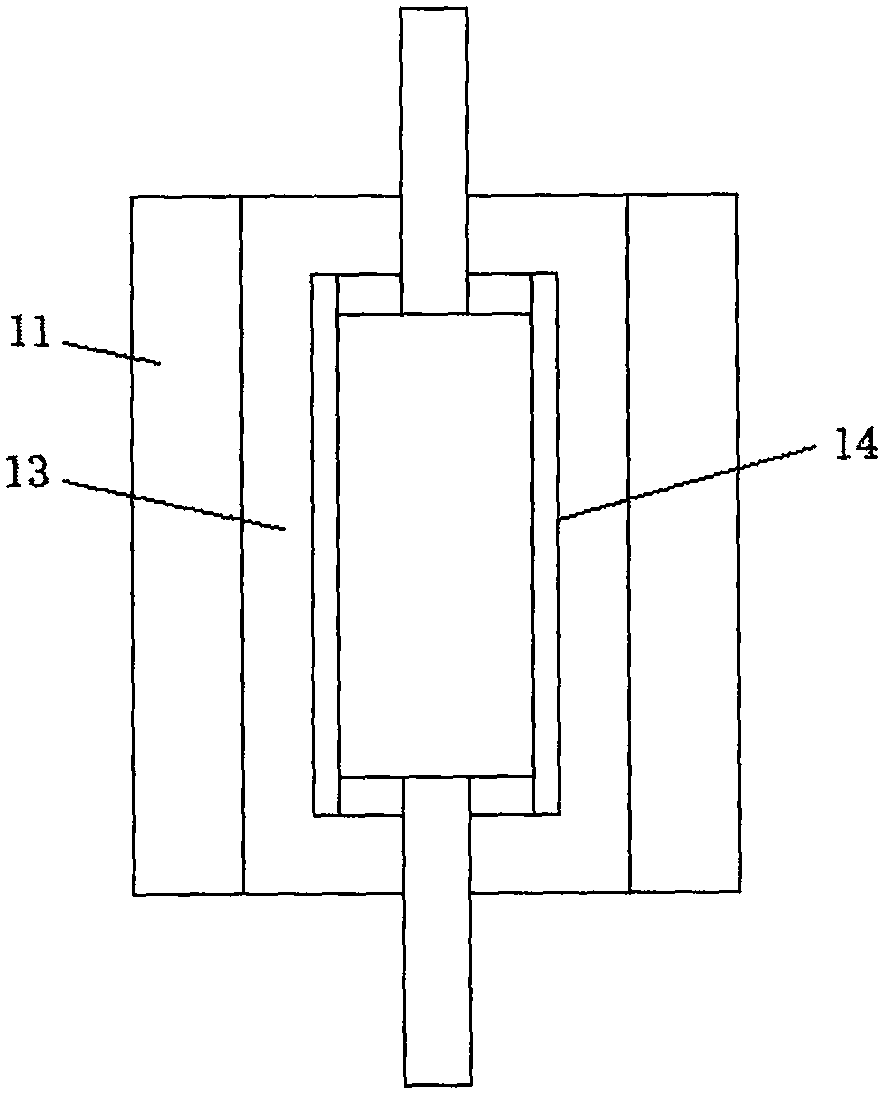

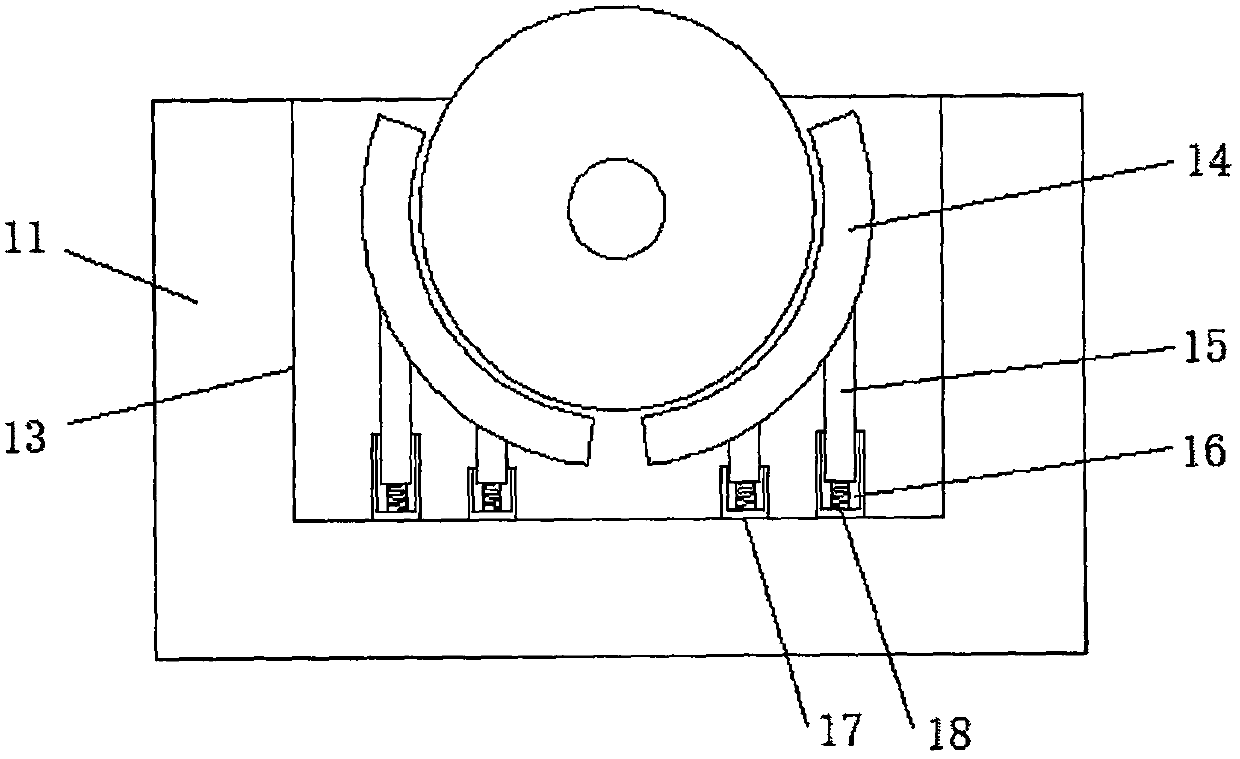

[0018] refer to Figure 1-3 , an automatic processing and production equipment for motor rotors, comprising a device body 1 and a controller installed in the device body 1, the device body 1 is a cavity structure, one side of the device body 1 is provided with a material inlet 2, and the device body 1 The other side is provided with a discharge port 10, a plurality of cylinders 4 are installed on the top of the equipment body 1, and a horizontally arranged moving plate 7 is arranged in the equipment body 1, and the moving plate 7 is fixedly connected with the piston rod of the cylinder 4, and the moving plate The top of 7 is equipped with the first rotating motor 5 by screw, the bottom end of moving plate 7 is connected with rotating rod 8, and rotating rod 8 is connected with the output shaft of the first rotating motor 5, and the bottom end of rotating rod 8 is equipped with grinding block 9. An infrared sensor 6 is also embedded in the bottom of the moving plate 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com