ZnO-NiO/rGO composite material with efficient electrocatalytic oxygen reduction performance

A composite material, zno-nio technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problem that potential materials have not been developed and reported, and achieve the effects of easy control of reaction parameters, cost reduction, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

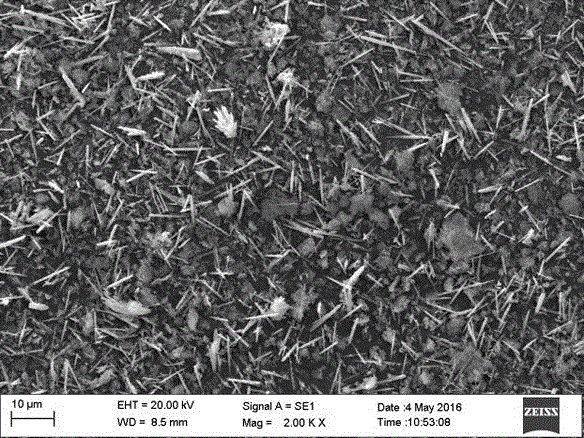

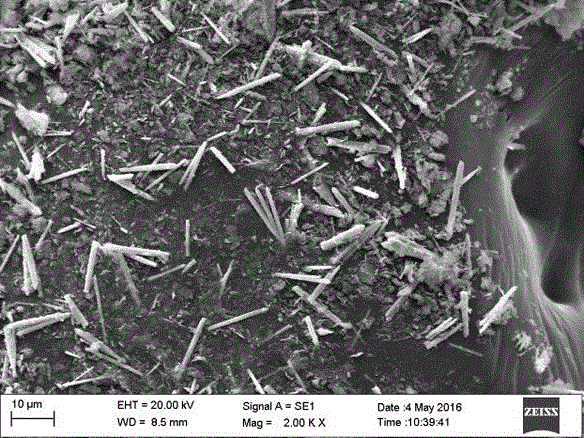

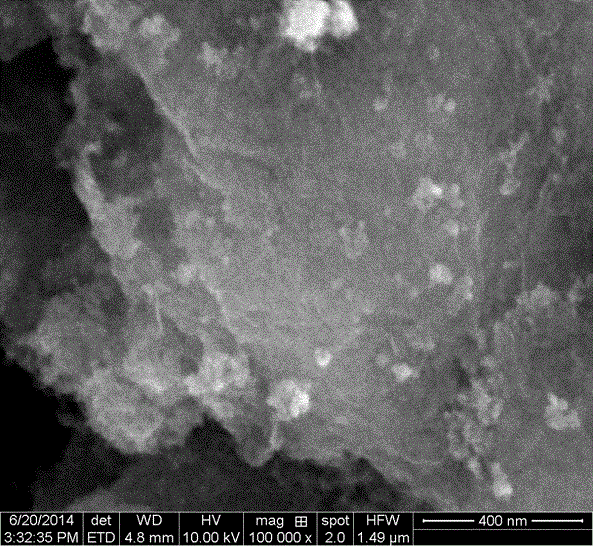

[0047] In a small 100 mL beaker, while stirring with a magnetic stirrer, add 40 mL of deionized water, and slowly add Zn(NO 3 ) 2 ·6H 2 O 1.48 g (0.005 mol), Ni(NO 3 ) 2 ·6H 2 O 1.46 g (0.005 mol), NaOH 1.60 g (0.04 mol), stirred for 5 min to form a light blue uniform liquid, add ethanol 10 mL, ethylene glycol 5 mL and 6 g / L graphene oxide 4 mL to fully stir the solution (about 10 min), transfer the reaction solution into a 100 ml autoclave, heat to 190 ºC, take it out after 24 hours at a constant temperature, wash the product three times with absolute ethanol, then wash three times with double distilled water, and put it in a vacuum Distilled under reduced pressure at 50 ºC for 20 min in a distillation device to obtain a black powdery solid, which is a ZnO-NiO / rGO composite material with high-efficiency electrocatalytic oxygen reduction performance. It has been detected that the mass ratio of ZnO-NiO to rGO in the ZnO-NiO / rGO composite is about 100:3, and the molar ratio...

Embodiment 2

[0050] In a small 100 mL beaker, while stirring with a magnetic stirrer, add 40 mL of deionized water, and slowly add 1.48 g (0.005 mol) of Zn(NO 3 ) 2 ·6H 2 O , 1.46g (0.005mol) Ni(NO 3 ) 2 ·6H 2 O and 1.60 g (0.04mol) NaOH, stirred for 5 min to form a light blue homogeneous liquid, add 10 mL of ethanol, 5 mL of ethylene glycol and 6 mL of 6 g / L graphene oxide and stir the solution fully (about 10 min) , transfer the reaction solution into a 100 ml autoclave, heat to 190 ºC, take it out after 24 hours at a constant temperature, wash the product three times with absolute ethanol, then wash three times with double distilled water, put it in a vacuum distillation device at 50 ºC Distilled under reduced pressure for 20 min, a black powdery solid was obtained, which is the ZnO-NiO / rGO composite material with high-efficiency electrocatalytic oxygen reduction performance. It has been detected that the mass ratio of ZnO-NiO to rGO in the ZnO-NiO / rGO composite is about 100:5, and...

Embodiment 3

[0053] In a small 100 mL beaker, while stirring with a magnetic stirrer, add 40 mL of deionized water, and slowly add 1.48 g (0.005 mol) of Zn(NO 3 ) 2 ·6H 2 O, 1.46g (0.005mol) Ni(NO 3 ) 2 ·6H 2 O and 1.60 g (0.04mol) NaOH, stirred for 5 min to form a light blue homogeneous liquid, added 10 mL of ethanol, 5 mL of ethylene glycol and 5 mL of 6 g / L graphene oxide, and stirred the solution thoroughly (about 10 min ), transfer the reaction solution into a 100 ml autoclave, heat to 190°C, take it out after 24 hours at a constant temperature, wash the product three times with absolute ethanol, then wash three times with twice distilled water, and put it in a vacuum distillation device at 50°C Distilled under reduced pressure for 20 min to obtain a black powdery solid, which is the ZnO-NiO / rGO composite material with high-efficiency electrocatalytic oxygen reduction performance. It has been detected that the mass ratio of ZnO-NiO to rGO in the ZnO-NiO / rGO composite is about 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com