Preparation method for carbon/metal oxide nanofiber composite catalyst

A composite catalyst and nanofiber technology, applied in the field of nanomaterials, can solve problems such as poor electrical conductivity, high cost, and limited promotion and application, and achieve enhanced electrocatalytic performance for oxygen reduction, excellent oxygen evolution performance, and high-efficiency catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the carbon / metal oxide nanofiber composite catalyst of the present invention comprises the following steps: (a) dissolving a salt solution containing metal ions and a polymer in an organic solvent, and stirring to form a spinning precursor mixed solution; The metal ions are one or more transition metal ions; if nickel ions and cobalt ions are mixed, the concentration of the cobalt ions is twice the concentration of the nickel ions; (b) the spinning precursor Electrospinning the mixed solution to form a composite non-woven material; (c) placing the composite non-woven material in an inert gas atmosphere for high-temperature calcination to obtain a carbon / metal oxide nanofiber composite catalyst. The composite catalyst is a nanofiber composite catalyst with carbon fiber as the core and metal oxide particles embedded on the surface or inside of carbon nanofibers. It has good electrical conductivity, enhanced electrocatalytic performance for oxygen ...

Embodiment 1

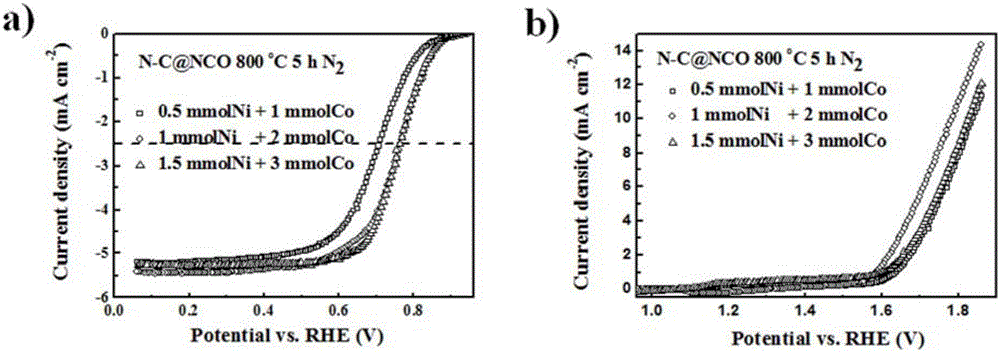

[0022] This example provides a method for preparing a carbon / metal oxide nanofiber composite catalyst (N-C@NCO), which includes the following steps:

[0023] (a) Dissolve a salt solution containing 1 mmol of nickel nitrate and 2 mmol of cobalt nitrate and 1.0 g of a polymer (polyacrylonitrile, MACKLIN, average molecular weight 150,000) in 10 mL of an organic solvent (DMF), and stir for 2 hours to form a spinning precursor body mixture;

[0024] (b) Place the spinning precursor mixture obtained in step (a) in an electrospinning apparatus for electrospinning to form a composite nonwoven material. The control parameters of the electrospinning apparatus are: voltage 15V, injection speed 0.5 mm / min, the receiving distance is 15mm, and the fiber filaments with a diameter of about 1~2mm are obtained;

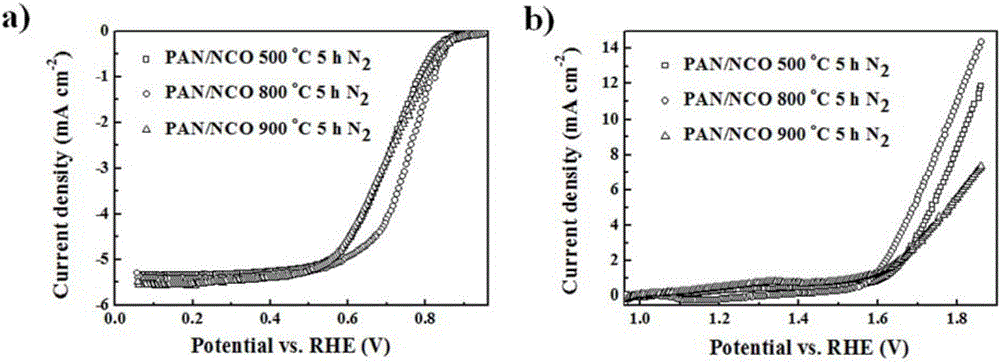

[0025] (c) Put the above-mentioned composite non-woven material in a nitrogen atmosphere and calcinate at 800° C. for 5 hours. The prepared carbon / metal oxide nanofiber composite cat...

Embodiment 2

[0027] This example provides a method for preparing a carbon / metal oxide nanofiber composite catalyst, and its specific steps are basically the same as those in Example 1, except that in step (c), it is calcined at 500° C. for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com