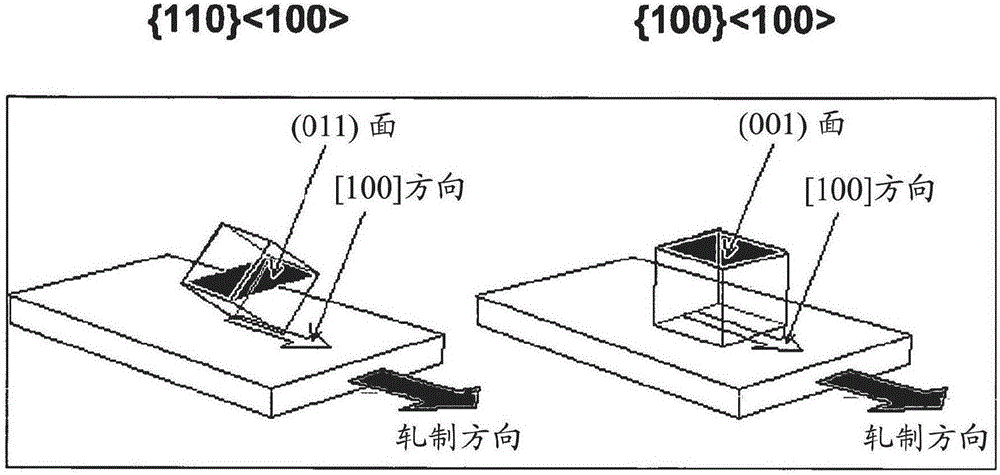

Semiconductor-based, large-area, flexible electronic devices on {110}<100> oriented substrates

A technology of electronic devices and semiconductors, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

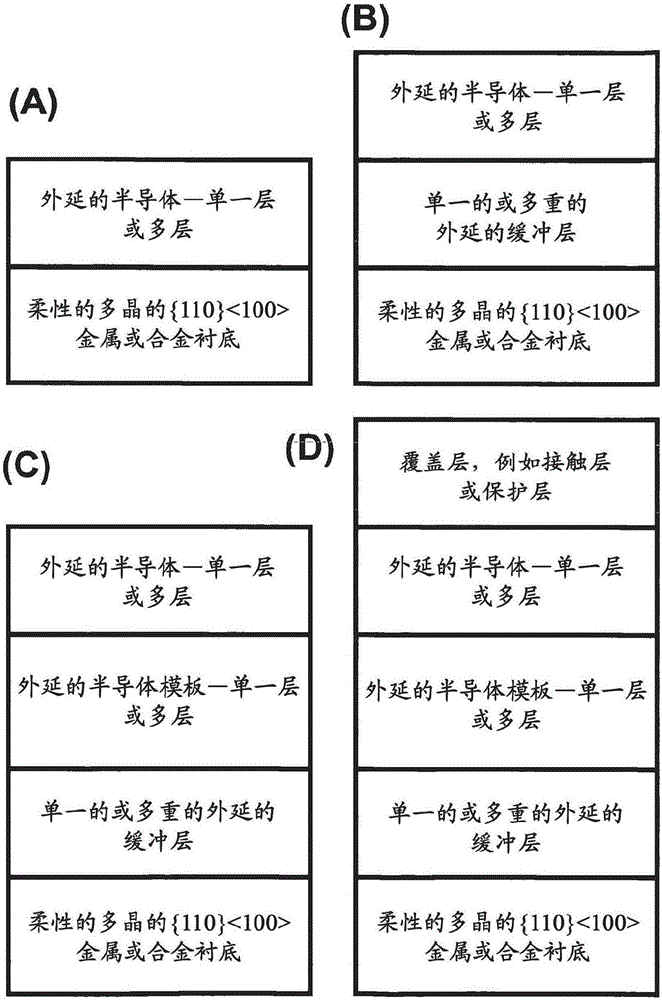

Method used

Image

Examples

Embodiment 1

[0096] Example 1: [100] uniaxially textured metal substrates were prepared by successively pressing or forging cubic metals or alloys by compression to a large total deformation and then recrystallization annealing. For example, a NiW alloy with 3-9 at% W is used, compressed to 90% deformation by uniaxial extrusion, and then annealed in a furnace at a temperature above the primary recrystallization temperature of the alloy. The primary recrystallized texture formed is the [100] texture. By increasing the annealing temperature to a high temperature close to 1000°C, an average grain size of greater than 100 μm is formed. An epitaxial buffer layer is then deposited on the substrate. For example, chemical vapor deposition (CVD) is used to deposit epitaxial TiN layers at deposition temperatures ranging from 300°C to 600°C. An epitaxial Si layer is then deposited using a CVD type process at a deposition temperature ranging from 300°C to 900°C. This results in the formation of a [...

Embodiment 2

[0097] Example 2: [110] uniaxially textured metal substrates were prepared by successively pressing cubic metals or alloys by compression to a large total deformation and then recrystallization annealing. For example, a NiW alloy with 3-9 at% W is used, compressed to 90% deformation by uniaxial extrusion, and then annealed in a furnace at a temperature above the primary recrystallization temperature of the alloy. The primary recrystallized texture formed is the [110] texture. By increasing the annealing temperature to a high temperature close to 1000°C, an average grain size of greater than 100 μm is formed. An epitaxial buffer layer is then deposited on the substrate. For example, chemical vapor deposition (CVD) is used to deposit epitaxial TiN layers at deposition temperatures ranging from 300°C to 600°C. An epitaxial Si layer is then deposited using a CVD type process at a deposition temperature ranging from 300°C to 900°C. This results in the formation of a [110] uniaxi...

Embodiment 3

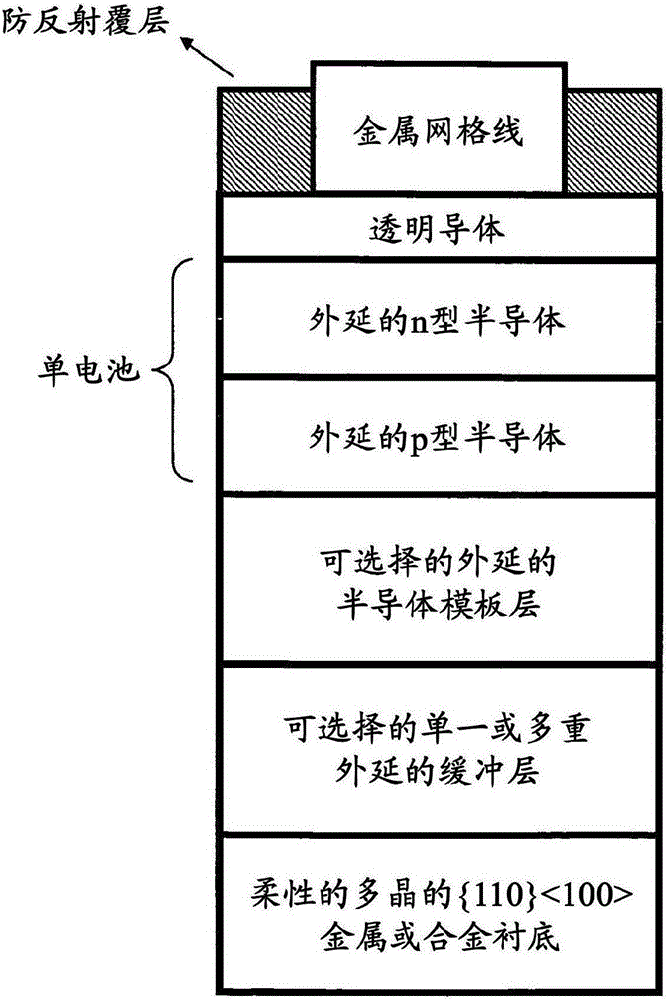

[0098] Example 3: Figure 10 Shown in cross-section of a crystallographically textured, flexible NiW alloy with a textured Si semiconductor layer over the alloy and an epitaxial buffer layer of textured TiN in between idealized schematic diagram. [100] textured biaxially textured Ni-3at%W was prepared by continuous rolling of powder metallurgy obtained alloy coils from a thickness of about 120 mils to a foil thickness of about 2 mils or 50 microns. The rolled crystallographic texture of the foil or strip is the standard Cu-type rolled texture of greatly deformed FCC metals. After degreasing and drying the tape, the tape was loaded into a reel-to-reel high vacuum (10-8 Torr) chamber containing a radio frequency induction furnace. The strip was pulled through the hot zone of the furnace under a partial pressure of ~3 x 10-7 Torr of hydrogen sulfide gas at a rate such that each section was heated to 1250° C. in twenty minutes, so as to be on the surface of the strip. A sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com