Iron-silicon-aluminum-ferrite composite magnetic core and preparation method therefor

A technology of ferrite core and sendust, which is applied in transformer/inductor core, inductance/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problem that switching power supply devices are vulnerable to damage and reactive power consumption increase, switching loss and other issues, to achieve the effect of improving the power factor of the power supply, reducing transient loss, and reducing current distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the sendust-ferrite composite magnetic core described in the above technical solution, comprising the following steps:

[0031] (1) Mixing the sendust powder and the insulating coating agent to obtain a mixed material;

[0032] (2) Molding the mixed material obtained in the step (1) with the ferrite core to obtain a green body; said molding makes the mixed material coated on the surface of the ferrite core;

[0033] (3) preheating the green body obtained in the step (2) and then annealing to obtain a sendust-ferrite composite magnetic core.

[0034]The invention mixes the sendust aluminum alloy powder and the insulating coating agent to obtain the mixed material. In the present invention, the mixing temperature is preferably 15-130°C, more preferably 20-120°C, more preferably 40-100°C, most preferably 80-90°C; in the present invention, the mixing The speed is preferably 5-60r / min, more preferably 15-55r / min, m...

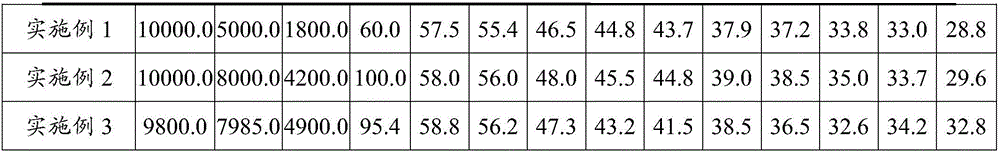

Embodiment 1

[0044] Mix 300-mesh sendust aluminum powder with a weight of 29.6 grams, 0.2 g phosphoric acid and 0.2 g sodium silicate at room temperature for 10 minutes at a mixing rate of 5 to 60 r / min to obtain a mixed material; wherein the sendust aluminum powder has a chemical composition of Iron 87.8%, silicon 6.8% and aluminum 5.4%.

[0045] Put 12g of the mixed material into the mold of OD33.02mm×ID19.90mm×HT15mm, and then put the nickel-zinc ferrite powder core with the mass of 3g and the size of OD30mm×ID25mm×HT3mm into the mold, and the mass of nickel-zinc The ratio is 0.4:0.6, and finally put the remaining 18g of mixed material into the mold, and the pressure reaches 21T / cm 2 Hold for 10s at the same time, and the green body is obtained by ejecting the mold;

[0046] The green body was preheated at 200°C for 50 minutes under the condition of vacuum degree of 0.08Pa to obtain the sendust-ferrite composite magnetic core precursor;

[0047] Under the same vacuum condition, keep t...

Embodiment 2

[0049] Mix 200 meshes of sendust powder with a weight of 28.4 grams, 0.8 g of tetraethyl orthosilicate and 0.8 g of zinc stearate at a speed of 60 r / min at 80°C for 10 minutes to obtain a mixed material; the sendust powder The chemical composition of iron is 87.8%, silicon 6.8% and aluminum 5.4%.

[0050] Put 20g of the mixed material into the mold of OD33.02mm×ID19.90mm×HT15mm, then put 3g of manganese zinc ferrite core with the size of OD30mm×ID25mm×HT3mm into the mold, and finally put the remaining 10g of the mixed material Put it into the mold, pressurize 20T / cm 2 Hold for 15s, withdraw from the mold, and obtain the green body;

[0051] In the condition of nitrogen gas with a flow rate of 5L / min, after preheating at 250°C for 80 minutes, in the same atmosphere, annealing at 680°C for 80 minutes to obtain a sendust-ferrite composite core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com