Method for quantitative representation of leakage risk of oil-gas cap rock due to faulting effect

A quantitative characterization and fault technology, applied in geophysical measurement, instruments, etc., can solve the problems of inaccurate characterization of oil and gas caprocks, leakage risks, etc., and achieve the effects of improving drilling success rate, high accuracy, and reducing drilling risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

[0032] This method of quantitatively characterizing the seepage risk of oil and gas cap rocks due to faulting includes the following steps:

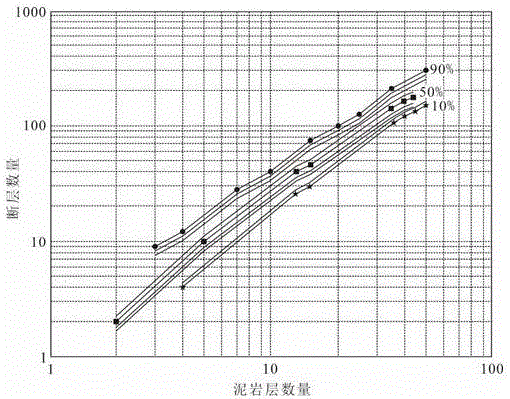

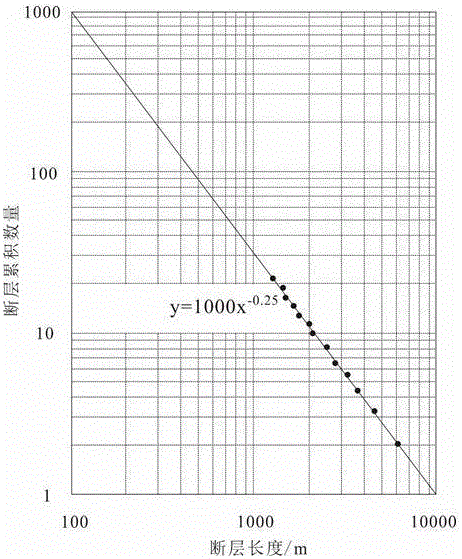

[0033] a. Establishment of cap rock and fault structure model: use core, imaging logging and conventional logging data to interpret the lithology (sandstone and mudstone) characteristics of the target layer, and determine the thickness of each layer of mudstone and sandstone and the cap rock The total thickness is used to establish caprock and fault structure models, and the model features are: The cap rock is composed of thick mudstone interbedded with thin sandstone; The mudstone layer has good sealing ability, and each layer of mudstone has a similar thickness, and the thin sandstone has good lateral and vertical connectivity, which can cause oil and gas migration; Faults are randomly distributed in the caprock. If the fault th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com