Annular specimen tensile testing device and realizing method thereof

A tensile test, ring-shaped technology, used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as incompatibility with tensile tests, high device manufacturing costs, and low-carbon energy saving. , to achieve the effect of clear force transmission path, cost saving and long-term cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

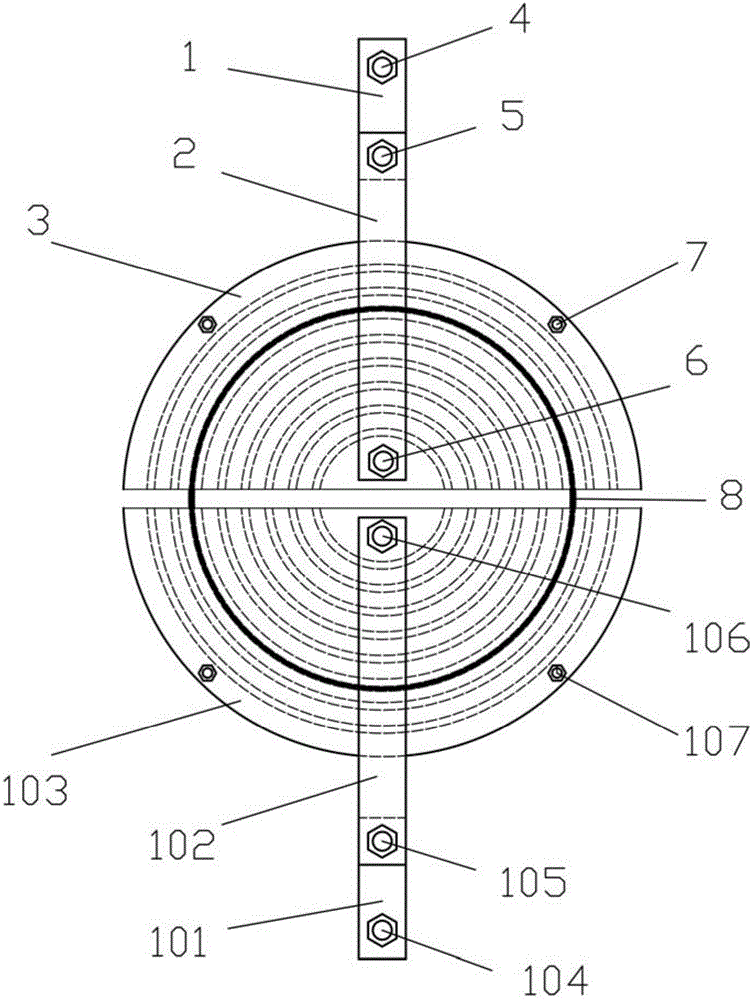

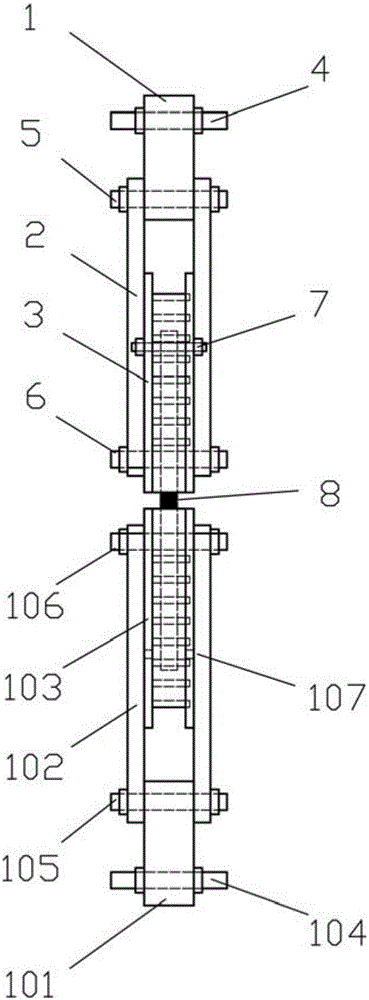

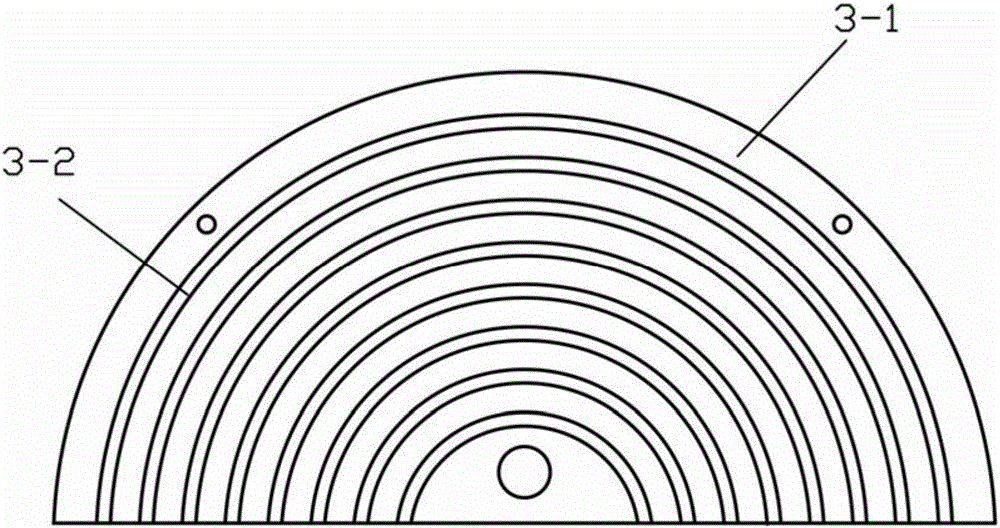

[0045] Such as Figure 1-7 As shown, a ring sample tensile test device includes a tensile device 9, a first connecting joint 1, a second connecting joint 101, a first connecting plate 2, a second connecting plate 102, a first separating disc 3, a second Separation disc 103, ring sample 8, first equipment bolt 4, second equipment bolt 104, first connecting bolt 5, second connecting bolt 105, first fixing bolt 6, second fixing bolt 106, first limit bolt 7 and the second limit bolt 107, wherein the first connecting joint 1 is connected to the tension device 9 through the first equipment bolt 4, and the second connecting joint 101 is connected through the second equipment bolt 104 Connected with the tension device 9; the first connecting plate 2 is connected with the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com