Pneumatic Opposite Action Piston Pump

A plunger pump and action technology, which is applied to piston pumps, pumps, and components of pumping devices for elastic fluids, etc., can solve problems such as low efficiency and high power consumption, and achieve energy loss saving, power saving, The effect of reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

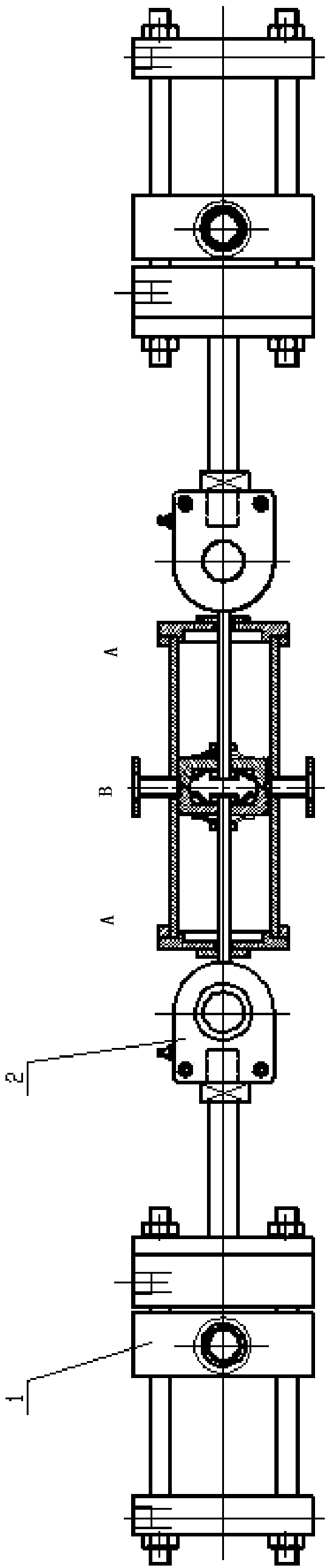

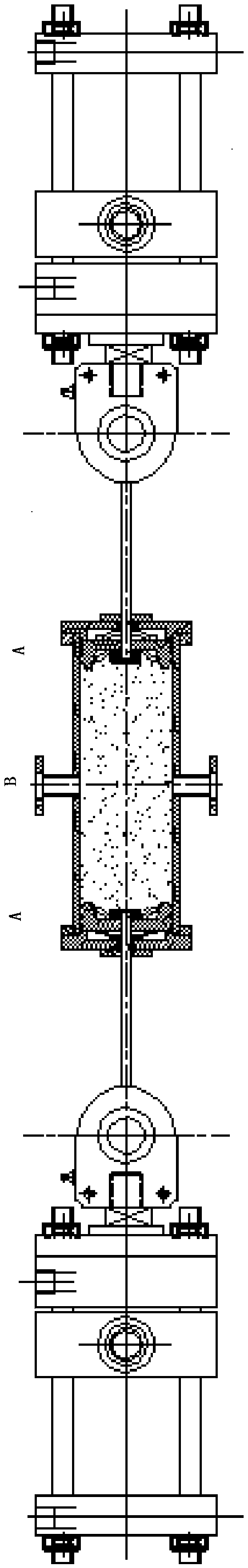

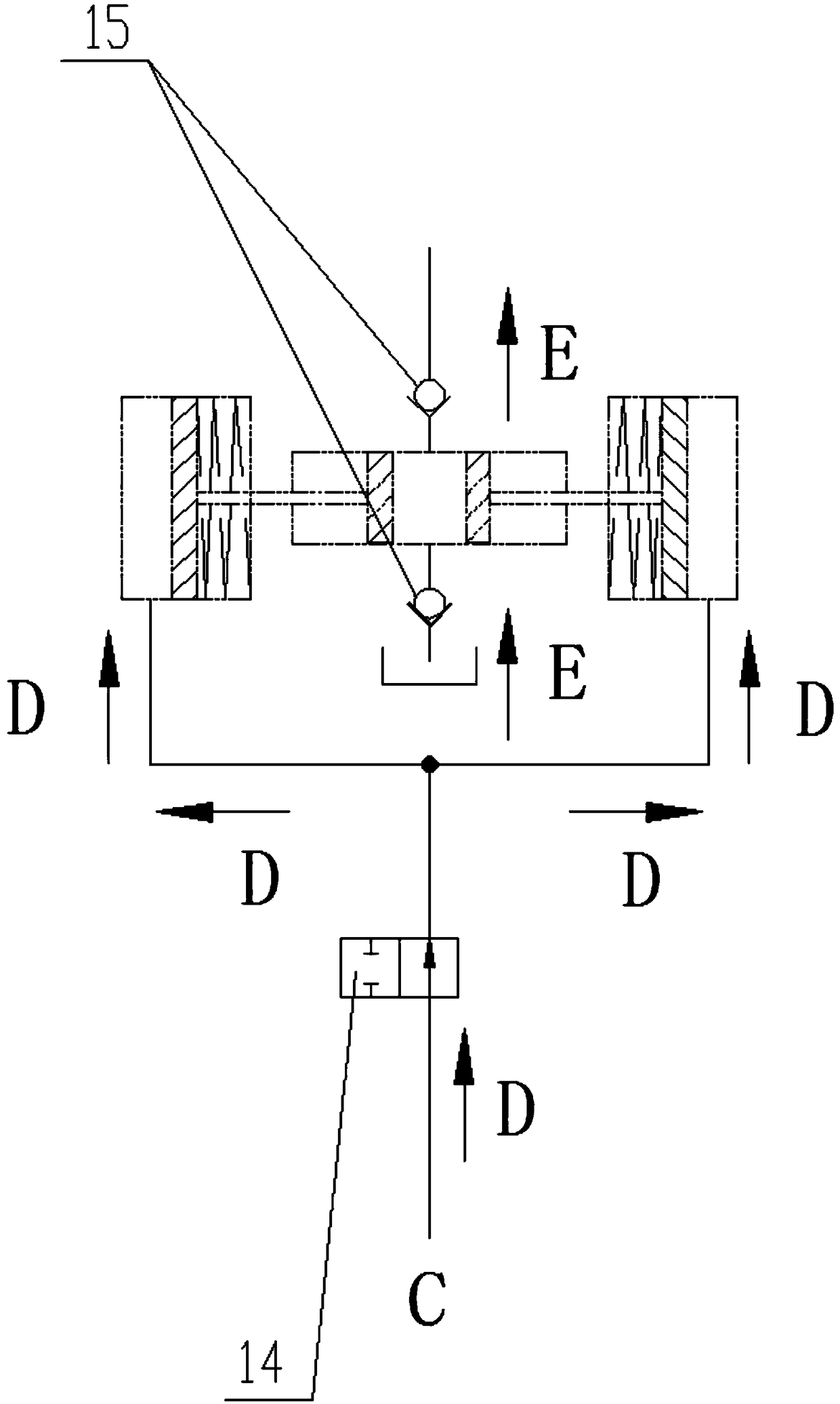

[0030] Such as Figure 1 to Figure 6 As shown, a pneumatic opposite-acting plunger pump includes a pump body 7, the pump body 7 is a casting, the inner cavity of the pump body 7 and the contact surface of the plug 10 have a Cr plating layer of 0.08 mm to 0.12 mm, and the preferred The inner cavity of the pump body 7 and the contact surface of the plug 10 have a 0.1mm Cr plating layer. Cr-plated layer, the surface of this coating is smooth and flat, which reduces the frictional resistance between the sealing ring and the cavity; and this coating has a relatively strong anti-rust ability, because the medium water quality of the continuous casting workshop is complex and there are corrosion factors, so the existence of the Cr-plated layer can Greatly extend the service life of the pump.

[0031] The left and right sides of the inner cavity of the cylindrical pump body 7 are respectively provided with a group of plug bodies, and the upper and lower sides of the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com