Axial current force curtain sail current wheel

A technology of flow curtain and sail flow wheel, which is applied to wind turbines, wind turbines, wind turbine control and other directions that are consistent with the wind direction, can solve the problem that the three-blade wind wheel has less flow area and weak flow power, increases transportation costs and Installation costs, high mold costs, etc., to achieve the effect of improving the use value, reducing selectivity, and eliminating mold production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

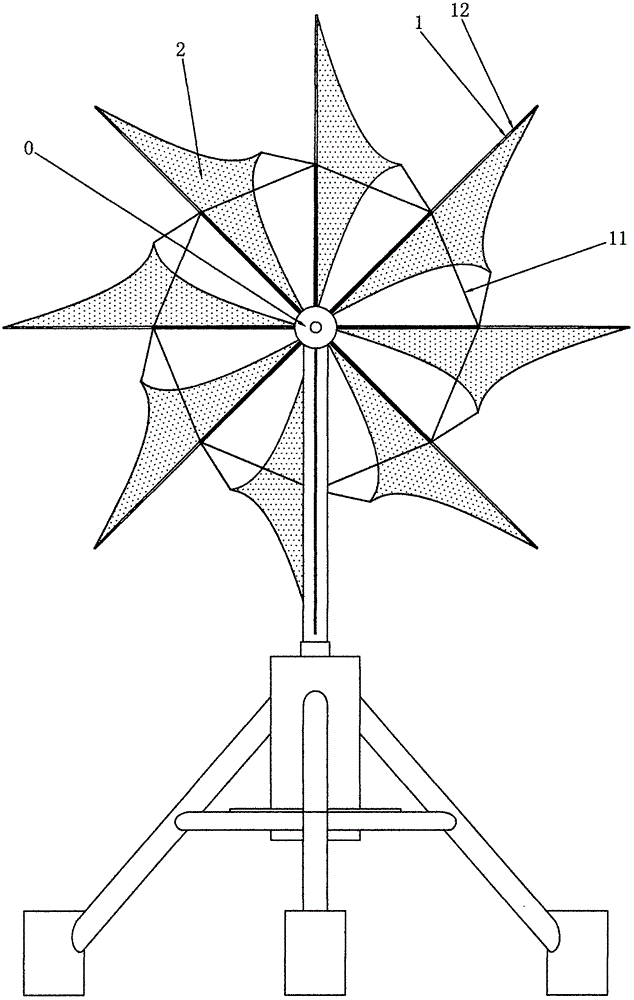

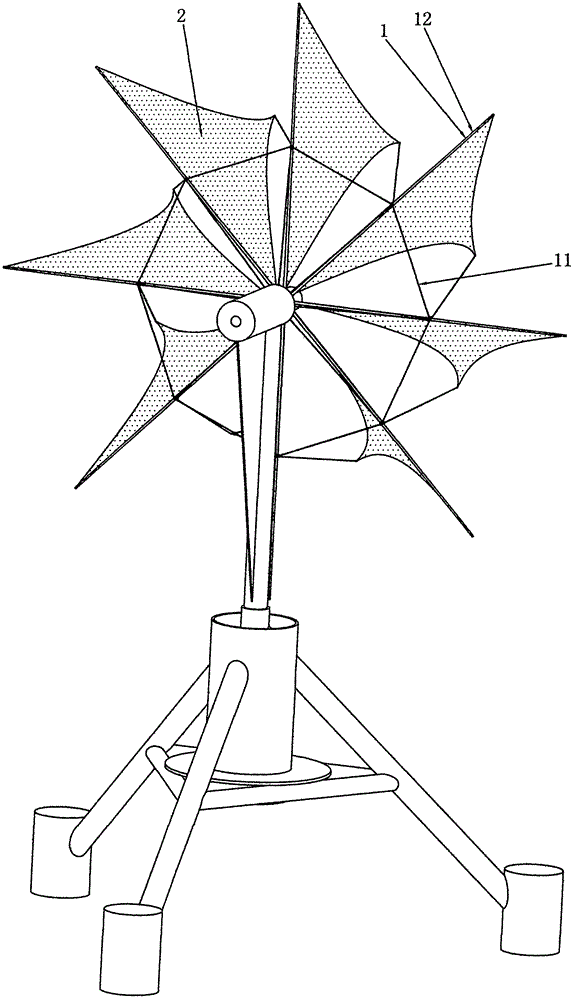

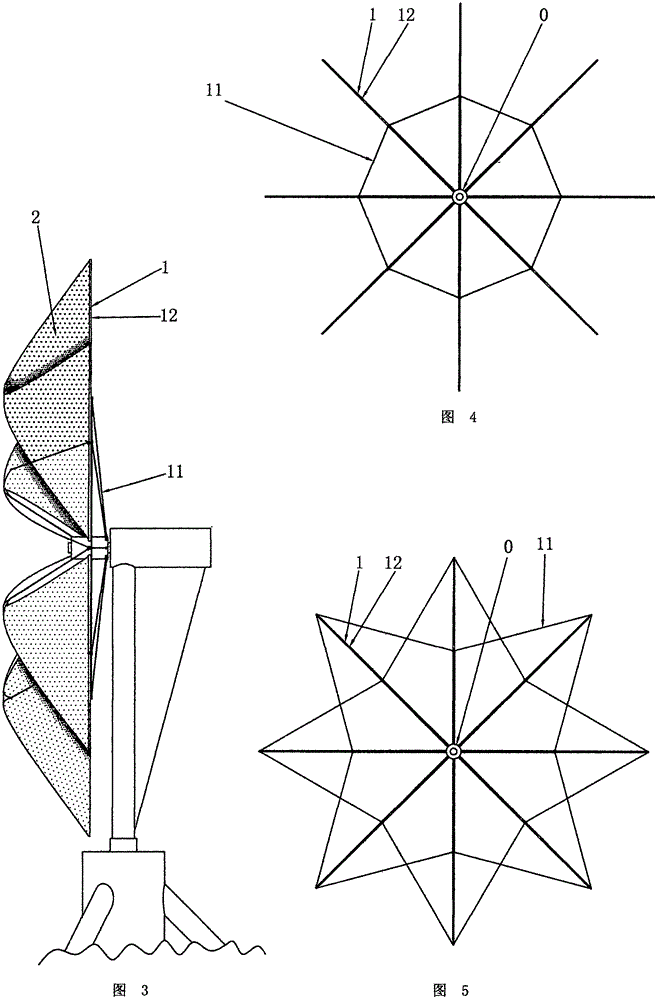

[0058] Axial flow curtain sail wheel, as shown in Figure 17, 19, 20, 21, 22, 32, it includes: flow wheel frame 1, curtain sail 2; described flow wheel frame 1 is composed of outer wheel 10, wheel hub 0 , a chain cable 11 or a strut 12; the outer wheel 10 has at least one outer ring or an outer circular tube body and an outer frame; the chain cable 11 is a chain or a rope; the chain cable 11 or a strut 12 surround the wheel hub 0 in an axial ring array and connect the two ends of each piece to tighten or tighten the hub 0 and the outer wheel 10 to be coaxial and concentric; 0 axial annular array; or the curtain sail 2 artificially swings or stretches on the wheel frame 1 and surrounds the hub 0 axial annular array.

[0059] Axial flow curtain sail wheel, such as figure 1 , 2, 4, 5, 6, 7, 9, 10, 29, 30, it includes: a wheel frame 1, a curtain sail 2; 11; the strut 12 is fixed on the hub 0 with one end and surrounds the hub 0 in an axial circular array; the chain cable 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com