Three-level buffering heavy-load elastic backing plate and three-level buffering vibration-damping method

An elastic backing plate and three-stage cushioning technology, which is applied in the field of vibration reduction, can solve the problems of local node static stiffness failure, local node static stiffness large, and the overall performance of the backing plate, etc., to achieve good water resistance and smooth deformation. Rebound, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

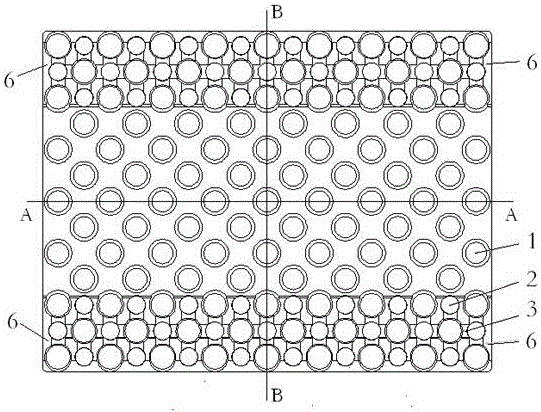

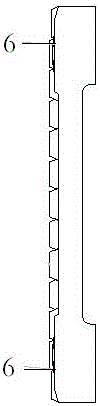

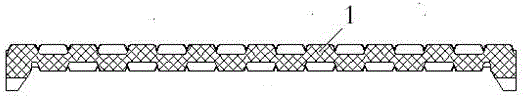

[0023] As shown in Figures 1 to 4, a three-stage cushioning heavy-duty elastic backing plate includes a main body of the backing plate, and the main body of the backing plate is mainly composed of two different main bodies, that is, the middle body 5 and the body connected integrally with the middle body Two side bodies, the two side bodies include two side bodies 4 symmetrically distributed on both sides of the middle body. The upper surface and the lower surface of each side body are all set to be respectively higher than the stepped surface 6 of the upper surface and the lower surface of the middle body, that is, the upper surface of the side body is higher than the upper surface of the middle body, and the lower surface of the side body is convex. Out of (higher than) the lower surface of the middle body. On the step surface, high-position large bosses and low-position small bosses are arranged. On the same surface of the main body of the backing plate, the stepped surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com