Textile finishing resin and preparation method thereof

A technology of fabric finishing and resin, which is applied in the field of fabric finishing resin and its preparation, can solve the problems of low non-ironing properties of fabrics, affecting fabric whiteness, excessive use of dialdehyde, etc., and achieve high non-ironing level, low yellowing degree, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

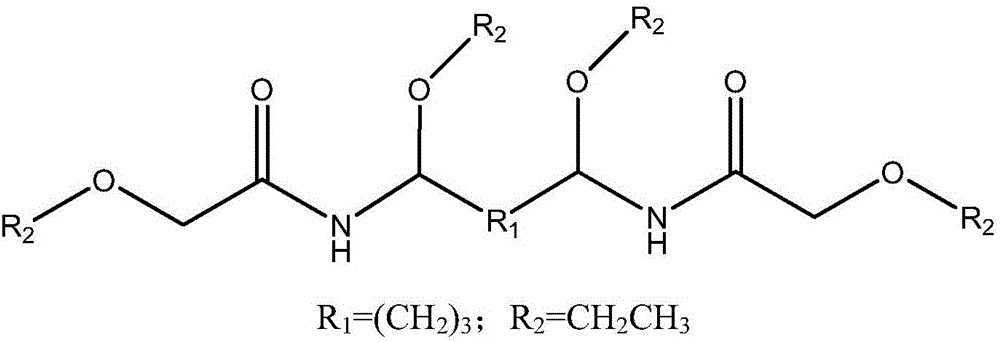

Image

Examples

Embodiment 1

[0025] Embodiment 1, concrete steps are as follows:

[0026] 1) Add 150g of glycolamide, 145g of glyoxal and 75g of water with a mass fraction of 40% in a round-bottomed flask equipped with a mechanical stirrer and a reflux condenser, heat and maintain the mixture at a temperature of 50°C for 3 hours, during which Use 37g mass fraction as 20% aqueous solution of sodium carbonate pentahydrate to adjust and maintain the pH of the mixed solution at 7.5;

[0027] 2) Use 7.1 g of 50% sulfuric acid aqueous solution to adjust the pH of the mixture to 5, and react at 40° C. for 3 hours;

[0028] 3) After the reaction is completed, the temperature of the mixed solution is cooled to 30°C, and the mixture is distilled under reduced pressure while stirring. The vacuum pressure is -0.1MPa. The mixed solution is heated and kept at 47°C, and condensate flows out. When no liquid flows out from the condenser Stop heating and vacuuming, let stand and cool to 40°C;

[0029] 4) Use 5.8 g of sul...

Embodiment 2

[0033] Embodiment 2, concrete steps are as follows:

[0034] 1) Add 150g of glycolamide, 200g of glutaraldehyde and 75g of water with a mass fraction of 50% in a round-bottomed flask equipped with a mechanical stirrer and a reflux condenser, heat and maintain the mixture at a temperature of 70°C for 4 hours, during which Use 14g mass fraction of 20% sodium hydroxide aqueous solution to adjust and maintain the pH of the mixed solution at 7.5;

[0035] 2) Use 14.0 g of 50% toluenesulfonic acid aqueous solution to adjust the pH of the mixture to 5, and react at 50° C. for 3 hours;

[0036] 3) After the reaction is completed, the temperature of the mixed solution is cooled to 30°C, and the mixture is distilled under reduced pressure while stirring. The vacuum pressure is -0.1MPa. The mixed solution is heated and kept at 47°C, and condensate flows out. When no liquid flows out from the condenser Stop heating and vacuuming, let stand and cool to 40°C;

[0037] 4) Use 11.2 g of 50%...

Embodiment 3

[0041] Embodiment 3, concrete steps are as follows:

[0042] 1) add 150g glycolamide, 145g glyoxal (market

[0043] sale, mass fraction 40%) and 75g water, heating and maintaining 60 ℃ of system temperature reaction 3.5 hours, need in the process

[0044] Use 19.6g potassium hydroxide aqueous solution (mass fraction is 20%) to adjust and maintain the system pH at 7.5-8;;

[0045] 1) Add 150g of glycolamide, 145g of glyoxal and 75g of water with a mass fraction of 40% in a round bottom flask equipped with a mechanical stirrer and a reflux condenser, heat and maintain the temperature of the mixture at 60°C for 3.5 hours, during which Use 19.6g mass fraction of 20% potassium hydroxide aqueous solution to adjust and maintain the pH of the mixed solution at 8;

[0046] 2) Use 6.3 g of 50% phosphoric acid aqueous solution to adjust the pH of the mixture to 5, and react at 40° C. for 3.5 hours;

[0047] 3) After the reaction is completed, the temperature of the mixed solution is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com