A spray type bulk fiber treatment process

A treatment process and technology for loose fibers, applied in the field of spray-type loose fiber treatment technology, can solve the problems of dense fiber web structure, limited fiber web thickness, and fiber web easily broken, etc., and achieves good processing fluency, improved processing efficiency, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

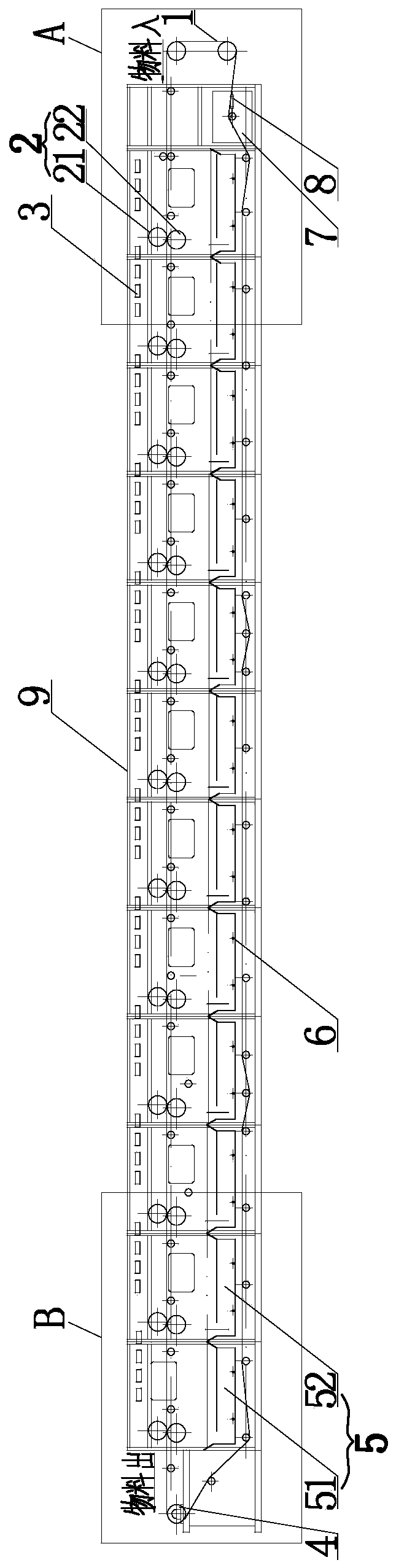

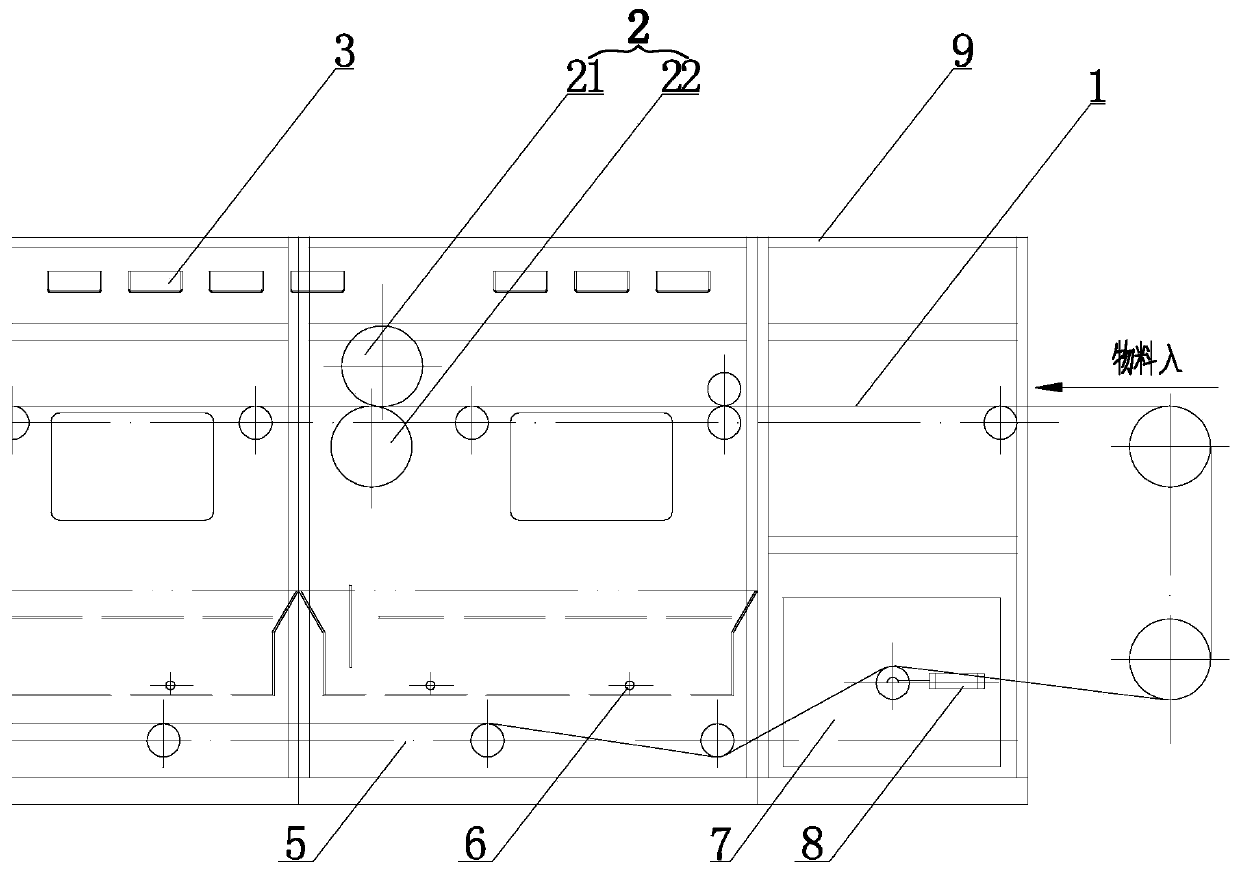

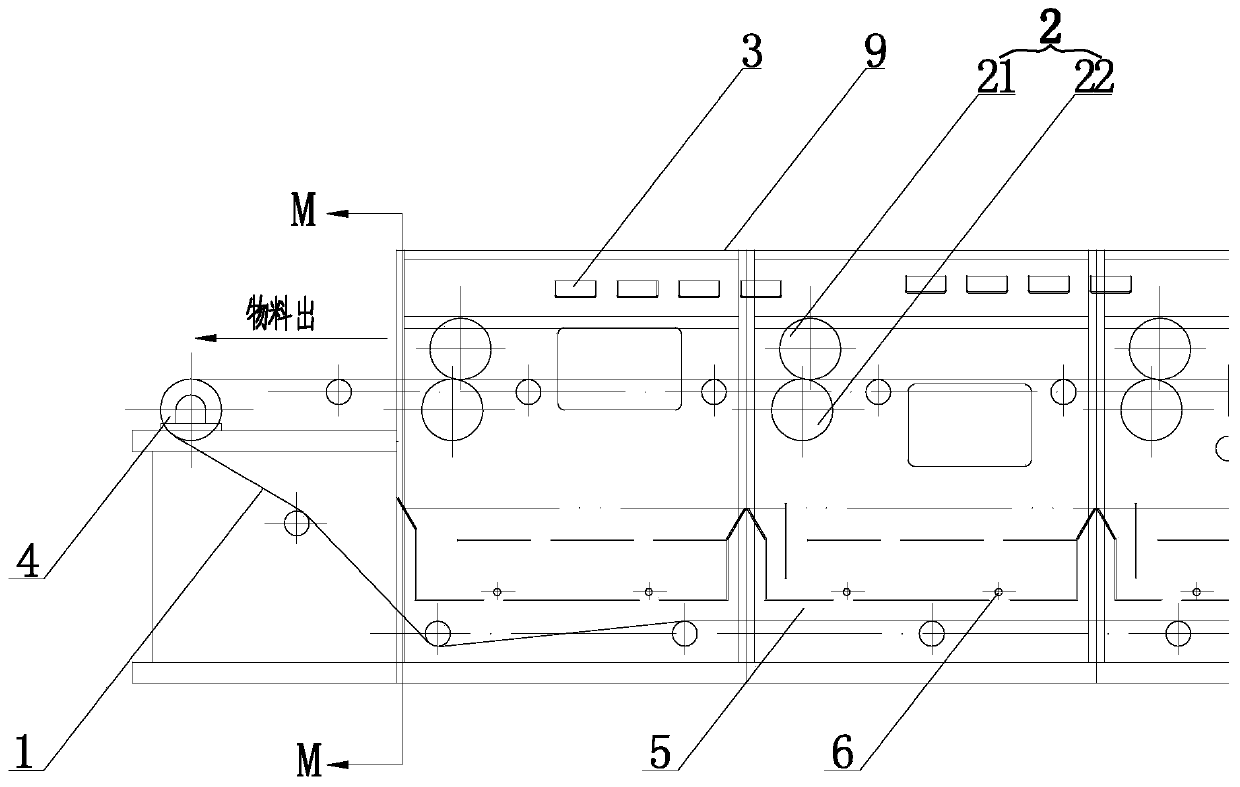

[0028] A kind of spraying type bulk fiber processing technology of present embodiment, combines figure 1 , figure 2 and image 3 , the loose fibers to be processed are placed on the processing net 1, and the processing net 1 rotates under the drive of the driving roll 4, and several groups of rolls 2 are arranged along the advancing direction of the processing net 1, and the rolls 2 include an upper roll 21 and a lower roll 22, and the upper roll 2 The roll 21 and the lower roll 22 are separated above and below the processing net 1, the central axis of the upper roll 21 is misaligned with the central axis of the lower roll 22, and the central axis of the upper roll 21 passes through the lower roll 22, and the upper roll 21 and the lower roll 22 The direction of rotation is opposite, so as to drag the loose fibers to advance with the treatment net 1; the treatment liquid is sprayed down from the treatment tank 3 above the upper roll 21, and the loose fibers on the treatment n...

Embodiment 2

[0036] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: a processing liquid tank 5 is arranged under the processing network 1 for receiving and supplying the processing liquid to the processing tank 3; a heating pipe 6 is arranged in the processing liquid tank 5 to treat A water tank 7 is arranged below the net 1 for supplying clear water and adjusting the concentration of the treatment liquid; a heat exchanger 8 is arranged in the water tank 7 for stabilizing the temperature of the clear water and the treatment liquid and for stabilizing the temperature of the treatment liquid.

[0037] The treatment liquid enters from the treatment liquid tank in the last area 51 (that is, along the direction of the treatment network, near the outlet of the box body), and is pumped into the treatment tank 3. After overflowing, the fiber material is processed, and the treatment liquid returns to this tank. In the next treatment li...

Embodiment 3

[0039] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: at the position close to the outlet of the box body 9, fixing seats 92 are respectively fixed on the opposite side walls 91 of the box body 9, and the fixing seats 92 are installed There is an upper platen 93 and a lower supporting plate 94, and the processing net 1 is fixed between two opposite fixed seats 92, and the upper pressing plate 93 is inclined downward, and a baffle plate 95 is arranged towards one end of the processing net 1, and the baffle plate 95 can be set to have Elastic rubber plate, the lower supporting plate 94 is positioned at the bottom of the processing net 1, both can fix the fixing seat together with the upper pressing plate 93, and can fix the processing net 1 together with the upper pressing plate 93 again. The processed fiber is scraped off through the baffle plate 95 to prevent it from being taken out by the outlet of the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com