Lindera glauca biomass diesel manufacturing process

A technology of biodiesel and production process, which is applied in the fields of biofuel, petroleum industry, fat oil/fat refining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

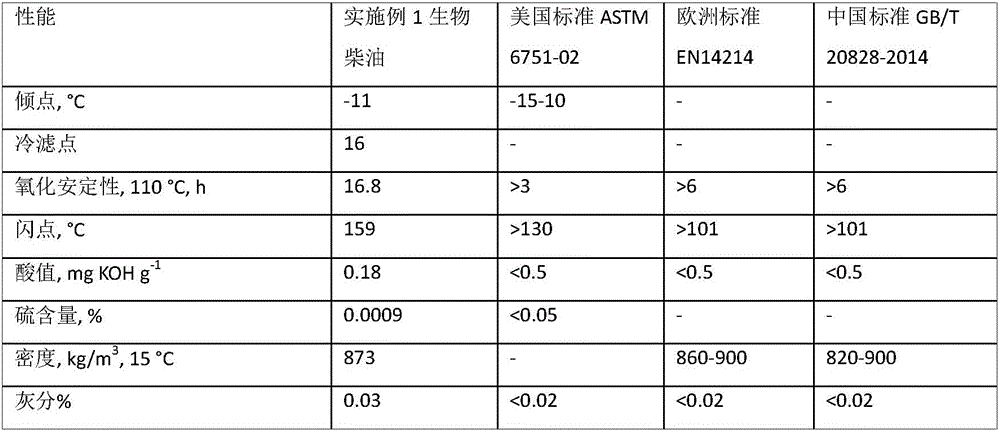

Embodiment 1

[0031] Embodiment 1 utilizes mountain pepper to prepare biological vegetable oil

[0032] A kind of mountain pepper biomass diesel oil production process, its concrete steps are as follows:

[0033] (a) using petroleum ether as a solvent, under the action of an ultrasonic instrument, carry out ultrasonic extraction to the mountain pepper powder under normal temperature conditions, the ultrasonic frequency is 40kHz, the ultrasonic extraction time is 40min, and crude oil is obtained;

[0034] In this example, the mass ratio of peppercorn powder and petroleum ether is 1:8. In actual operation, the mass ratio of peppercorn powder and petroleum ether is controlled within the range of 1:6-10, and the purpose of the invention can be achieved. .

[0035] (b) Use a rotary evaporator to rotary steam the crude oil, add 250-300ml of crude oil each time, work at a temperature of 60-70°C and a rotation speed of 60rpm for 45-60min, and steam out the residual petroleum ether;

[0036] Then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com