A kind of rosin for soldering flux and its preparation method and application

A technology of flux and rosin, used in welding equipment, manufacturing tools, welding media, etc., can solve the problems of easy decomposition of rosin, irregular solder joints, uneven film formation, etc., to achieve good thermal stability, full solder joints, Good film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

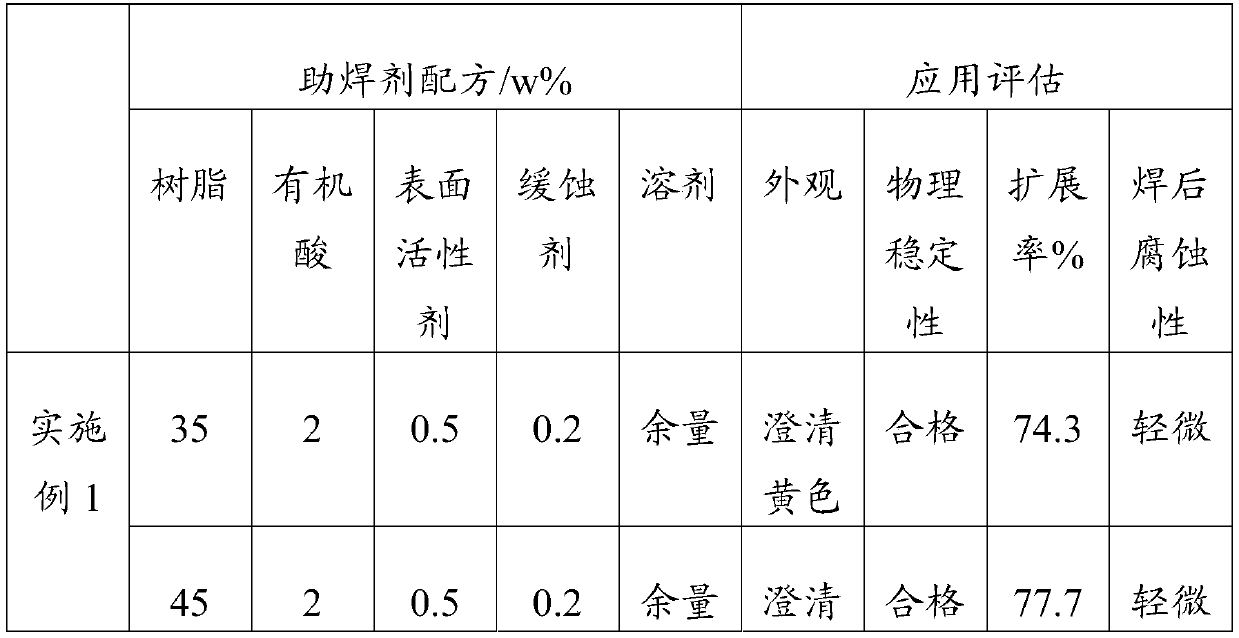

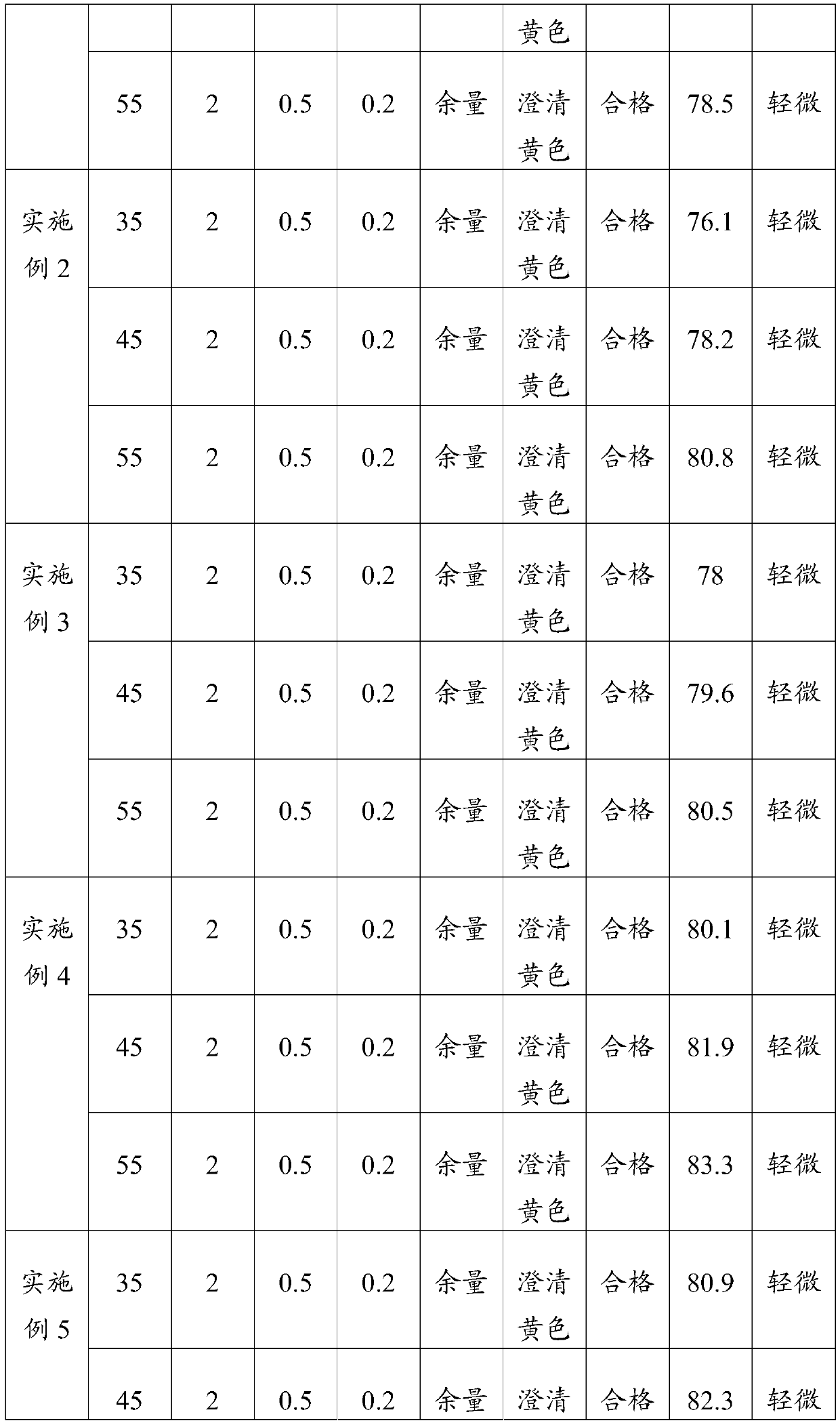

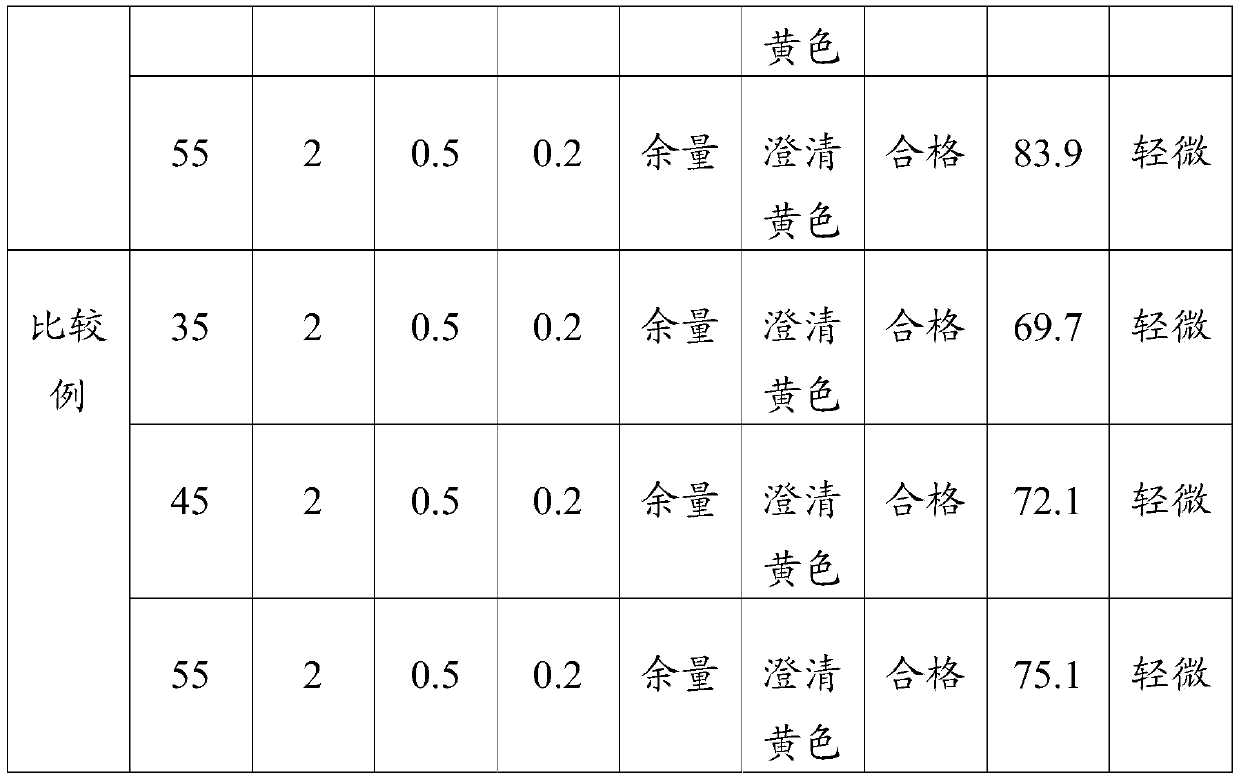

Examples

Embodiment 1

[0029] A kind of embodiment of rosin for soldering flux of the present invention, the rosin for soldering flux described in this embodiment is made up of the component of following mass percent: Laudanane type resin dibasic acid 12.0%, abietic acid 2.28%, dehydroabietic acid Acid 10.31%, dihydroabietic acid 57.3%, tetrahydroabietic acid 18.11%.

[0030] The composition of the above-mentioned rosin for soldering flux was analyzed by gas chromatography, and the softening point was 85.0° C. and the acid value was 175.0 mg KOH / g as measured by ring and ball method.

[0031] The preparation method of rosin for soldering flux described in the present embodiment is:

[0032] (1) Distillation: Weigh 700 grams of Nanya pine rosin, crush it and put it into a distillation bottle, and add tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.7 g, vacuumize, heat to 240°C, observe the ratio of the distilled matter in the receiving bottle with a marked scale,...

Embodiment 2

[0035] A kind of embodiment of the rosin for soldering flux of the present invention, the rosin for soldering flux described in this embodiment is made up of the component of following mass percent: Laudanane type resin dibasic acid 15.82%, abietic acid 2.33%, dehydroabietic acid Acid 10.66%, dihydroabietic acid 53.21%, tetrahydroabietic acid 17.98%.

[0036] The composition of the above-mentioned rosin for soldering flux is obtained by gas chromatography analysis, and its softening point is 92° C., and its acid value is 193.7 mg KOH / g as measured by ring and ball method.

[0037] The preparation method of rosin for soldering flux described in the present embodiment is:

[0038] (1) Distillation: Weigh 700 grams of Nanya pine rosin, crush it and put it into a distillation bottle, and add tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.7 grams, vacuumize, heat to 243 ° C, observe the proportion of the distillate according to the receiving b...

Embodiment 3

[0041] A kind of embodiment of the rosin for soldering flux of the present invention, the rosin for soldering flux described in this embodiment is made up of the component of following mass percent: Laudanane type resin dibasic acid 18.31%, abietic acid 2.5%, dehydroabietic acid Acid 12.51%, dihydroabietic acid 51.35%, tetrahydroabietic acid 15.33%.

[0042] The composition of the above-mentioned rosin for soldering flux was analyzed by gas chromatography, and the softening point was 98° C., and the acid value was 201 mg KOH / g as measured by the ring and ball method.

[0043] The preparation method of rosin for soldering flux described in the present embodiment is:

[0044] (1) Distillation: Weigh 700 grams of Nanya pine rosin, crush it and put it into a distillation bottle. Observing the distillate ratio in the receiving bottle with a good scale, distilling until the mass percentage of nanya pine acid in the residue in the distillation bottle is 19%, stop the distillation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com